Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

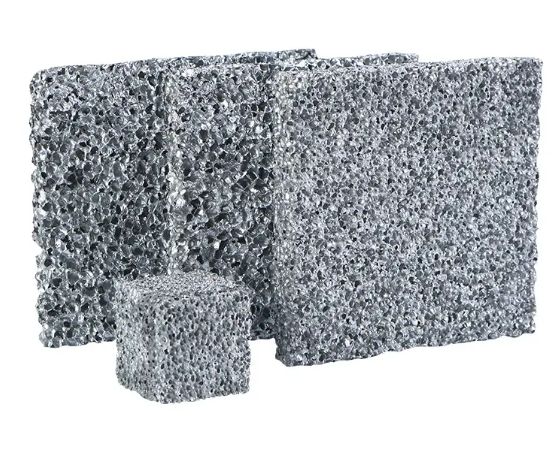

Aluminum Foam&Aluminum products

Product Details

In the aerospace industry, material selection is critical for achieving the perfect balance between strength, weight reduction, and performance. Foam aluminum has emerged as a game-changing material, offering a unique combination of high strength, low weight, and excellent energy absorption. These characteristics make it an ideal solution for lightweight aerospace components, improving efficiency, safety, and sustainability in aircraft and spacecraft design.

Structural Components

Foam aluminum is used in aerospace structures where weight reduction is crucial without compromising strength. It is applied in aircraft fuselage panels to enhance durability while reducing the overall weight, satellite components to improve launch efficiency and reduce payload costs, and spacecraft shielding for impact resistance against micrometeoroids and space debris.

Noise and Vibration Reduction

Aerospace environments demand noise control for both passenger comfort and operational efficiency. Foam aluminum is used in aircraft cabin walls and floors to dampen vibrations and improve acoustic insulation, as well as jet engine housings to absorb noise and improve operational efficiency.

Thermal and Fire Protection

With excellent heat resistance and fireproofing capabilities, foam aluminum plays a crucial role in heat shielding in spacecraft and aircraft interiors to protect against extreme temperature variations, thermal insulation in fuel tanks and engines to enhance safety and efficiency, and fire-resistant partitions for improved onboard safety.

Impact Protection and Energy Absorption

Foam aluminum is widely used in aerospace applications requiring high energy absorption, including crash-resistant panels to protect passengers and cargo during emergencies, landing gear shock absorbers to enhance durability and performance, and protective barriers for avionics and sensitive equipment against mechanical shocks.

Aerospace manufacturers prioritize materials that enhance fuel efficiency, safety, and sustainability. Foam aluminum meets these demands by offering lightweight construction that reduces fuel consumption and increases aircraft range, a high strength-to-weight ratio that provides structural integrity without adding unnecessary weight, superior heat and fire resistance that enhances safety in high-temperature environments, energy absorption capabilities that improve crashworthiness and impact protection, and corrosion and oxidation resistance that ensures durability in harsh operating conditions.

1. How can I contact with your company?

We are always ready to serve you via Email, Telephone, Fax, Skype, Whatsapp, Wechat or Mobile telephone.

2. What is your working time?

Monday-Saturday : 7:30AM-17:00PM (Beijing time, GMT+08.00)

We have public holiday during May.1-3, Oct.1-7 and Chinese New Year holiday . Pls email us during our holiday if u have any question.

3. Do you provide free samples?

Yes, we can provide a free sample for testing, buyer should bear all the shipping costs.

4. What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

5. What is the lead time?

Usually sample lead time is 7 days after payment has been confirmed.