Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

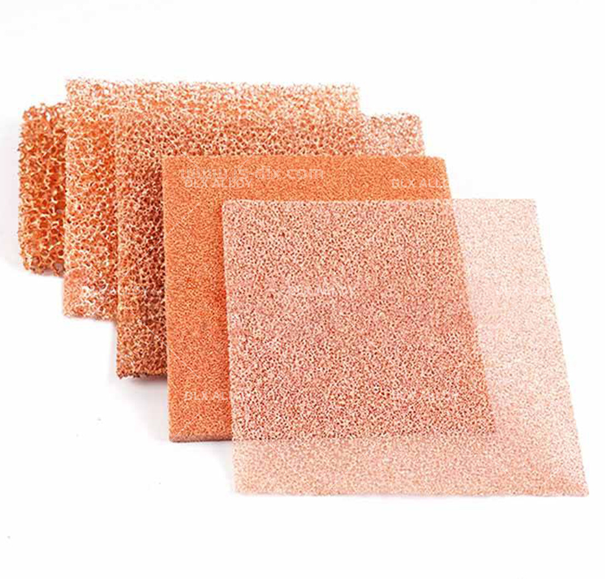

Copper Foam

Product Details

As industries and HVAC systems demand more efficient, lightweight, and high-performance heat transfer solutions, Copper Foam heat exchangers have emerged as a revolutionary innovation. Combining the high thermal conductivity of copper with a lightweight porous structure, copper foam significantly enhances heat dissipation and fluid flow efficiency. These properties make it an ideal choice for industrial cooling, HVAC systems, renewable energy solutions, and high-performance electronics.

Superior Thermal Conductivity

Copper has one of the highest thermal conductivities among metals, allowing heat exchangers to rapidly transfer and dissipate heat, improving cooling efficiency.

Porous Structure for Enhanced Heat Transfer

The open-cell structure of copper foam provides a larger surface area, facilitating more effective heat exchange between fluids or gases in HVAC and industrial cooling systems.

Lightweight and Space-Saving

Compared to traditional solid metal heat exchangers, copper foam offers a higher performance-to-weight ratio, making it ideal for compact and portable cooling applications.

Corrosion and Oxidation Resistance

Copper foam is highly resistant to corrosion, ensuring durability in harsh industrial and HVAC environments where exposure to moisture and chemicals is common.

Eco-Friendly and Recyclable

As a sustainable material, copper foam supports green energy initiatives and reduces environmental impact by being fully recyclable.

HVAC Systems and Air Conditioning Units

Used in air-to-air and air-to-liquid heat exchangers to improve cooling efficiency.

Enhances heat dissipation in air conditioning coils, refrigeration units, and ventilation systems.

Industrial Cooling and Thermal Management

Ideal for power plants, manufacturing facilities, and heavy machinery where high-performance cooling is required.

Applied in heat recovery systems to improve energy efficiency and reduce operational costs.

Electronics and Semiconductor Cooling

Essential for cooling high-power electronics, CPUs, GPUs, and data centers.

Helps prevent overheating in 5G infrastructure, telecommunication devices, and AI computing hardware.

Renewable Energy and Battery Thermal Management

Used in solar panel cooling systems and wind turbine heat exchangers to optimize energy efficiency.

Applied in electric vehicle (EV) battery cooling systems, ensuring longer battery life and improved safety.

Aerospace and Automotive Applications

Enables lightweight and high-performance cooling solutions in aircraft engines, space systems, and automotive radiators.

Supports turbocharged engine cooling, improving vehicle efficiency and reliability.

Medical and Laboratory Equipment

Used in precision cooling systems for MRI machines, laser devices, and pharmaceutical processing.

Ensures stable operating temperatures in sensitive research instruments.

Industries are increasingly seeking high-performance, energy-efficient, and cost-effective cooling solutions. Copper foam heat exchangers meet these demands by offering:

Higher heat dissipation efficiency, reducing overheating risks and improving equipment longevity.

Compact and lightweight designs, ideal for space-constrained applications.

Long-term durability, ensuring minimal maintenance costs and extended service life.

Environmental benefits, supporting sustainability efforts in industrial and HVAC applications.

1. How can I contact with your company?

We are always ready to serve you via Email, Telephone, Fax, Skype, Whatsapp, Wechat or Mobile telephone.

2. What is your working time?

Monday-Saturday : 7:30AM-17:00PM (Beijing time, GMT+08.00)

We have public holiday during May.1-3, Oct.1-7 and Chinese New Year holiday . Pls email us during our holiday if u have any question.

3. Do you provide free samples?

Yes, we can provide a free sample for testing, buyer should bear all the shipping costs.

4. What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

5. What is the lead time?

Usually sample lead time is 7 days after payment has been confirmed.