Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Nickel Foam

Product Details

Nickel Foam is a highly porous metal material composed primarily of nickel, offering unique structural and functional properties ideal for a range of industrial applications. Manufactured through a sintering process that fuses nickel powder into a continuous porous network, it provides excellent performance in various fields, including filtration, energy storage, and thermal management.

This lightweight, chemically stable material boasts exceptional electrochemical activity, making it suitable for applications such as batteries, fuel cells, and supercapacitors. Nickel foam is highly customizable in terms of porosity (ranging from 5ppi to 300ppi) and shape, ensuring it meets the specific needs of industries like automotive, aerospace, electronics, energy, and medical fields.

Material | Nickel foam, Sold in sheet |

Dimension | 500*1000, or customized as request |

Thickness | 0.5mm, 1.0mm, 1.5mm, 2.0mm,3.00mm etc |

The aperture | 80 PPI (5-80 PPI available) |

Porosity | 90-98% |

Through Hole Rate | ≥98% |

Bulk density | 0.25-1.00g/cm3 |

High Porosity: Nickel foam’s high porosity (ranging from 5ppi to 300ppi) provides a large surface area, making it ideal for applications like liquid and gas filtration, catalytic carriers, and as an electrode material in energy storage devices.

Excellent Conductivity: As a Metal Foam , nickel foam retains the conductivity of pure nickel, making it suitable for applications requiring electrical conductivity.

Chemical Stability: Nickel foam exhibits excellent resistance to a wide range of chemicals, ensuring reliable performance in harsh chemical environments.

Mechanical Strength: Despite its porous structure, nickel foam retains sufficient mechanical strength to withstand pressure and impact, making it durable in demanding environments.

Thermal Stability: Nickel foam maintains performance within a broad temperature range, making it suitable for heat dissipation and high-temperature applications.

Customizable: Nickel foam is available in various porosity levels (5ppi to 300ppi) and sizes, allowing for tailored solutions to meet the needs of specific applications.

Battery Electrodes: In lithium-ion batteries and other types of batteries, nickel foam serves as an excellent electrode material due to its high conductivity and porous structure, which supports efficient ion transmission.

Catalyst Carrier: The high surface area and chemical stability of nickel foam make it an ideal material for use as a catalyst carrier in chemical reactions, enhancing catalytic processes.

Filtration Material: The unique porous structure of nickel foam allows it to filter liquids and gases efficiently, making it useful in various filtration applications.

Sensors: Thanks to its electrochemical properties, nickel foam is used in sensors, especially in gas detection applications, to monitor and measure gas concentrations.

Heat Exchangers: With its excellent thermal conductivity, nickel foam is employed in heat exchangers, where it aids in efficient heat dissipation and temperature regulation.

High Surface Area: Nickel foam's porous structure provides a vast surface area, enhancing its effectiveness in applications like filtration, catalysis, and energy storage.

Thermal & Electrical Conductivity: It retains the high conductivity of nickel, making it an excellent material for energy-efficient applications such as heat exchangers and battery electrodes.

Chemical & Mechanical Stability: Nickel foam is resistant to corrosion and high pressures, ensuring its longevity and reliability in demanding applications.

Customizability: Available in a wide range of porosities (5ppi to 300ppi) and shapes, nickel foam can be tailored to meet the specific needs of various industries.

Cost-Effective: Despite its advanced properties, nickel foam is a cost-effective solution for industries looking for efficient materials that offer long-term durability and performance.

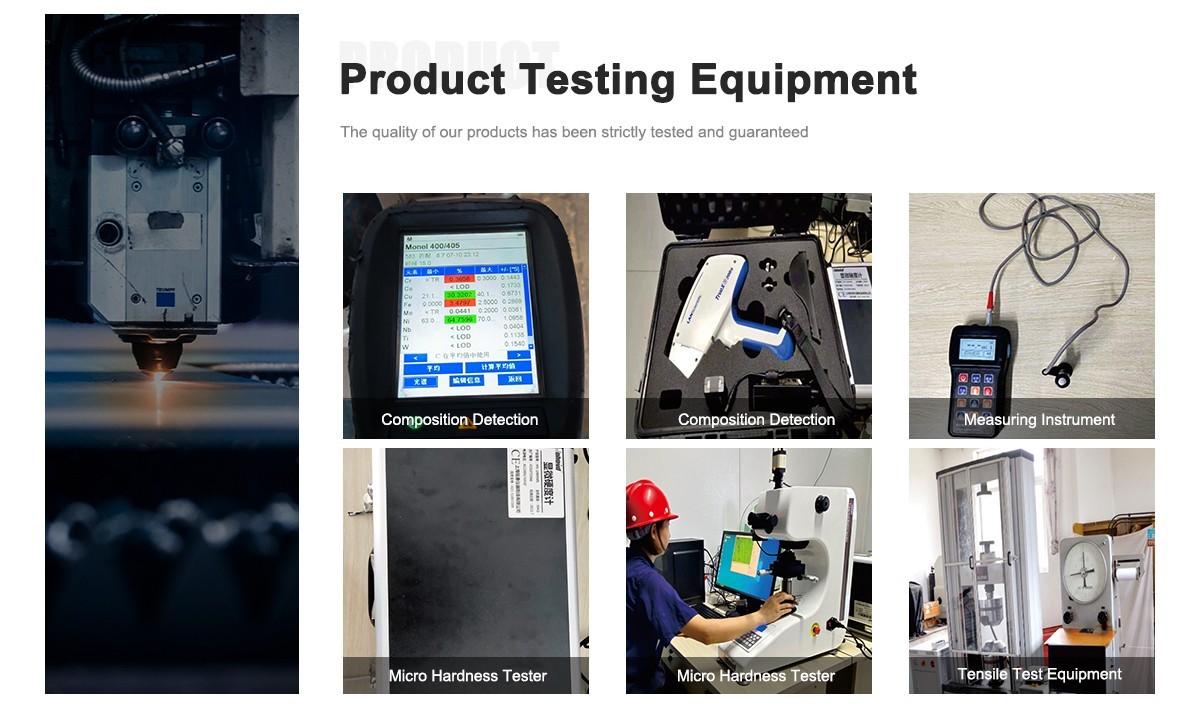

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got ISO9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, Precision Alloy , FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Q1: What is the range of porosity available for nickel foam?

A1: Nickel foam is available in a wide range of porosities, from 5ppi to 300ppi, allowing for tailored solutions depending on the application requirements.

Q2: How is nickel foam used in battery applications?

A2: Nickel foam is used as an electrode material in lithium-ion batteries and other types of batteries due to its excellent conductivity and porous structure, which supports efficient ion transmission.

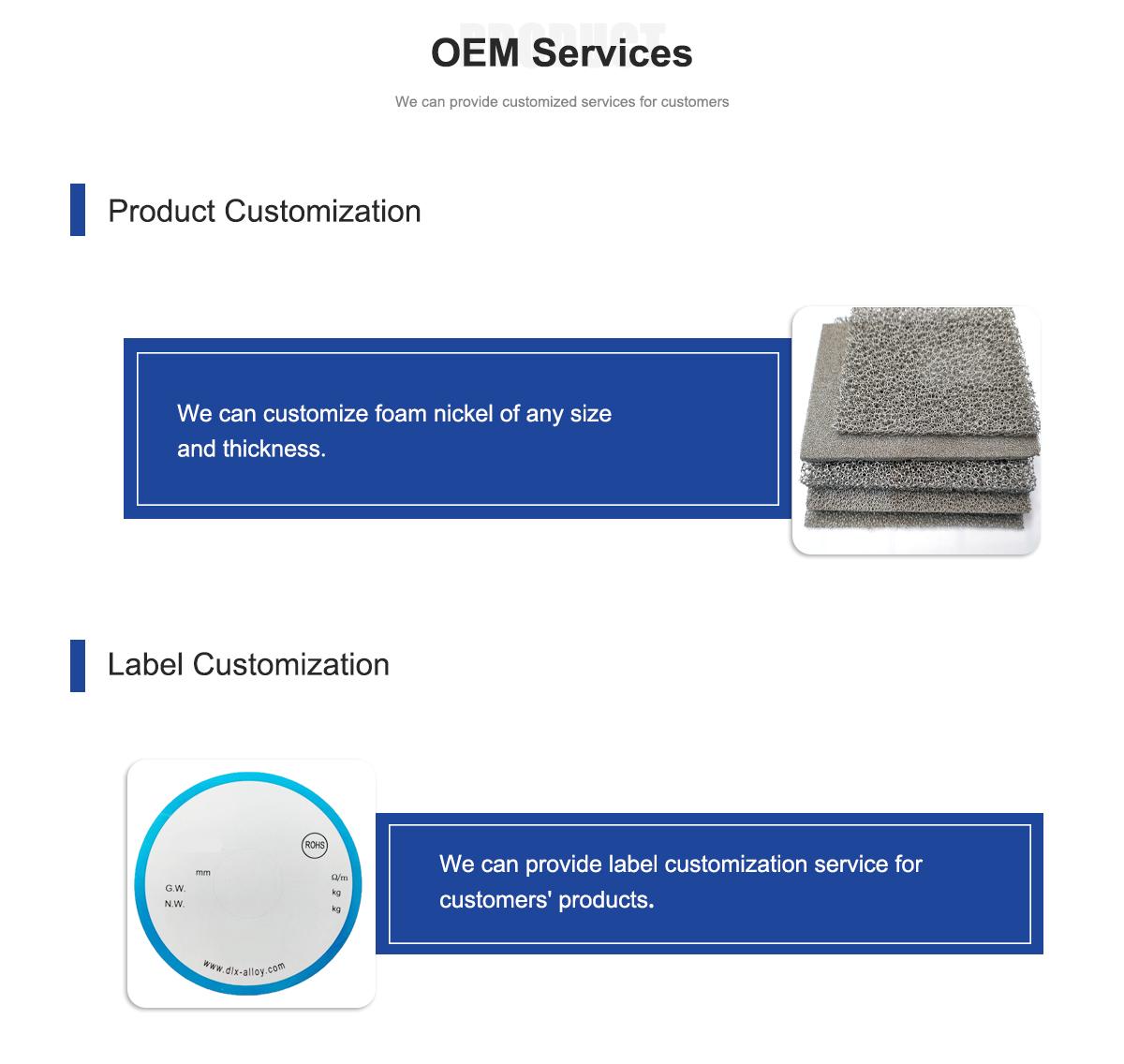

Q3: Can nickel foam be customized for specific applications?

A3: Yes, nickel foam is highly customizable in terms of size, shape, and porosity, allowing it to meet the specific needs of various applications like filtration, heat dissipation, and energy storage.

Q4: What are the advantages of using nickel foam in filtration applications?

A4: Nickel foam’s high porosity and large surface area make it an ideal material for liquid and gas filtration, ensuring effective filtration and stable flow rates.

Q5: Is nickel foam resistant to chemicals and high temperatures?

A5: Yes, nickel foam is chemically stable and resistant to various chemicals, making it suitable for use in aggressive environments. It also performs well under high-temperature conditions due to its thermal stability.

Q6: What industries use nickel foam?

A6: Nickel foam is widely used in industries such as automotive, aerospace, electronics, energy, medical, and chemical processing, where its unique properties are crucial for applications like filtration, battery manufacturing, heat dissipation, and more.

Q7: What is the lead time for custom nickel foam orders?

A7: The typical lead time for custom orders is 7-15 days after payment confirmation, depending on the quantity and customization requirements.

Q8: How can I contact your company for inquiries?

A8: You can contact us via email, phone, or through platforms like WhatsApp or WeChat. We are available Monday to Saturday, 7:30 AM – 5:00 PM (Beijing Time, GMT+08:00).