Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

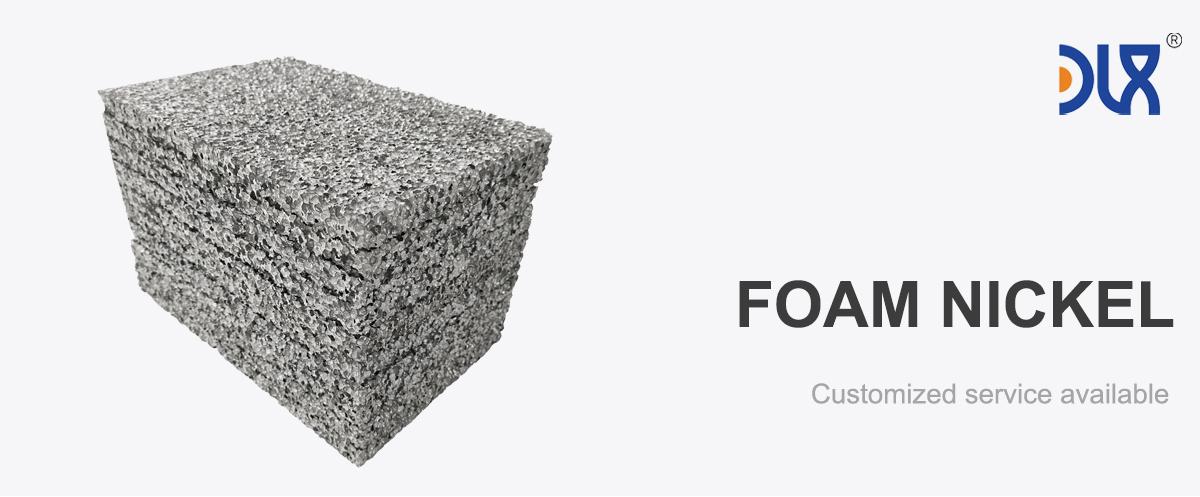

Nickel Foam

Product Details

Nickel foam is an advanced material that plays a pivotal role in energy storage solutions, particularly in modern battery systems. Due to its high porosity, excellent thermal conductivity, and superior mechanical strength, nickel foam is an essential component in the development of efficient and durable batteries. Its versatility makes it an ideal choice for a wide range of applications, including energy storage devices, industrial drying equipment, and other high-performance technologies.

Material | Nickel foam, Sold in sheet |

Dimension | 500*1000, or customized as request |

Thickness | 0.5mm, 1.0mm, 1.5mm, 2.0mm,3.00mm etc |

The aperture | 80 PPI (5-80 PPI available) |

Porosity | 90-98% |

Through Hole Rate | ≥98% |

Bulk density | 0.25-1.00g/cm3 |

High Porosity and Open Cell Rate: Nickel foam boasts an impressive porosity of 95-98%, with an open cell rate of ≥98%, which ensures high air permeability and a significant specific surface area. This property makes it ideal for applications such as exhaust gas purifiers and catalyst carriers.

Superior Thermal Conductivity: With a thermal conductivity greater than 3W/M.K, nickel foam ensures efficient heat dissipation, which is crucial for high-temperature applications, such as infrared burners and industrial drying equipment.

Mechanical Strength and Durability: Nickel foam is designed with an ultimate tensile strength of ≥2-7MPa, making it a robust material that can withstand significant mechanical stress. This durability is especially important for use in batteries and high-performance systems.

Temperature Resistance: Nickel foam can withstand temperatures of up to 500℃, ensuring its reliability in environments that require high-temperature resistance, such as heating applications in various industrial and civil equipment.

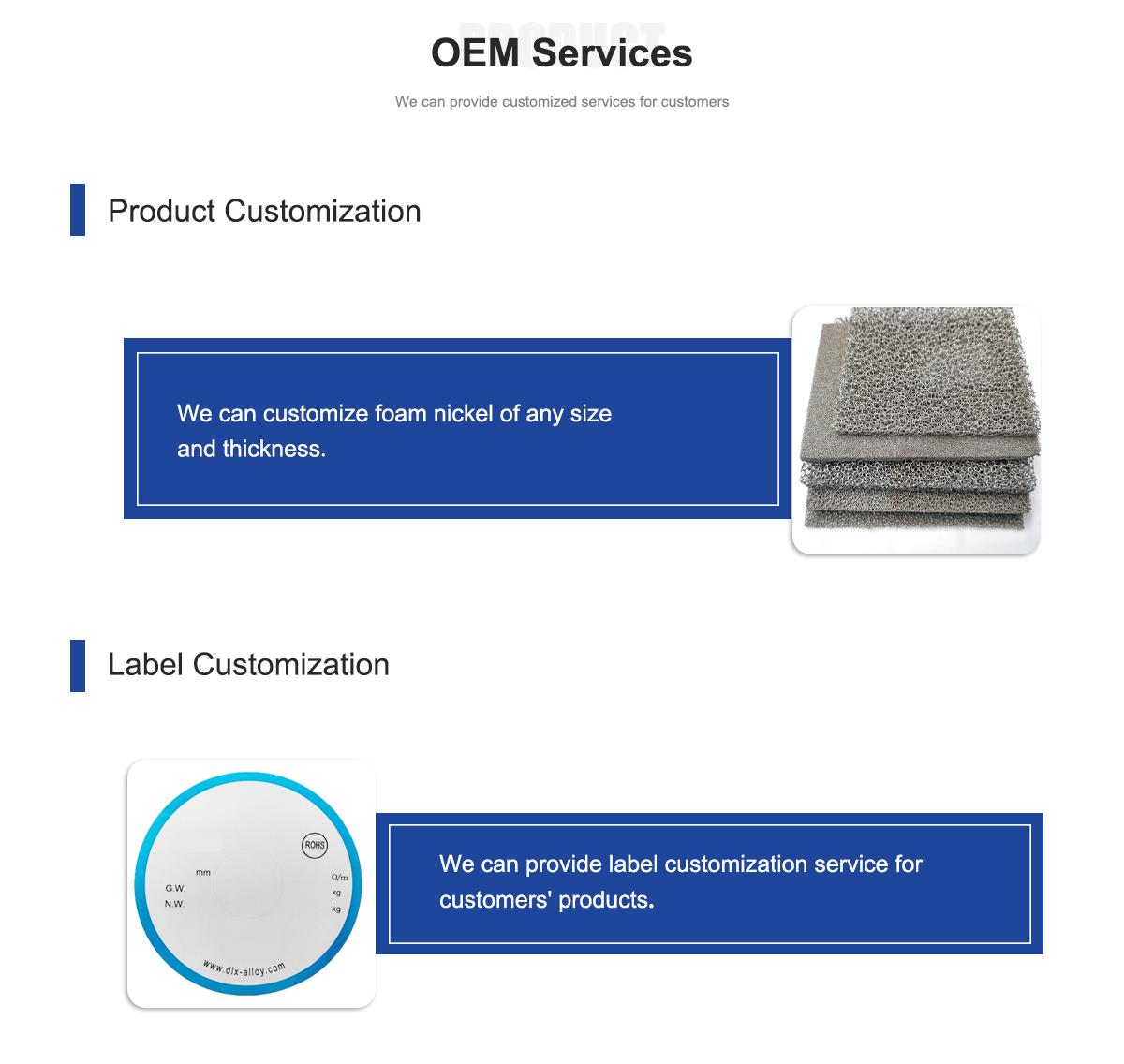

Customization: Available in various thicknesses (1-30mm) and cell sizes (5-150 PPI), nickel foam can be tailored to meet the specific requirements of different industries and applications.

Purity: With a minimum nickel content of 99.7%, nickel foam offers excellent electrical conductivity and chemical stability, making it a prime choice for battery electrodes and other electronic applications.

Nickel foam is used in a wide array of applications, owing to its unique combination of properties. Below are some of the key industries and applications where nickel foam proves indispensable:

Battery Electrodes: The high surface area and conductivity of nickel foam make it an ideal material for battery electrodes, particularly in rechargeable batteries used in energy storage systems, electric vehicles, and portable devices.

Energy Storage Devices: Nickel foam is utilized in energy storage technologies like supercapacitors and fuel cells, where its high porosity, mechanical strength, and thermal stability contribute to enhanced energy storage and efficient power release.

Exhaust Gas Purifiers: Its high porosity and resistance to corrosion make nickel foam an ideal material for exhaust gas purification systems, where it serves as the catalyst support material.

High-Temperature Filter Materials: Nickel foam's temperature resistance and corrosion resistance make it suitable for use in high-temperature filtration applications, particularly in chemical processing and industrial drying systems.

Infrared Burners and Heating Equipment: With excellent thermal conductivity, nickel foam is often used as a surface material in infrared burners and other high-temperature heating equipment, ensuring efficient heat transfer and stability.

Drying Equipment: In industrial and civil drying equipment, nickel foam provides reliable thermal management, enhancing the efficiency of heat exchange and speeding up the drying process.

The production of high-quality nickel foam involves several key steps to ensure the final product meets the strict requirements of various industries. The nickel foam is manufactured by a foaming process, where nickel metal is transformed into a highly porous structure. During this process, the material is carefully controlled to ensure consistent porosity, strength, and thermal properties.

After the foam is produced, it is treated to improve its surface area and mechanical properties, making it suitable for specific applications. The foam can be further customized in terms of thickness and cell size to suit different industrial needs. The final product is then thoroughly tested for quality assurance, ensuring that it meets the necessary performance and durability standards.

Efficient Energy Storage: Due to its high surface area and conductivity, nickel foam enhances the efficiency of energy storage systems, making it ideal for use in advanced battery technologies.

Long-Lasting Durability: With excellent mechanical strength and temperature resistance, nickel foam offers a long service life, reducing the need for frequent replacements and ensuring sustained performance in demanding applications.

Versatility in Applications: Nickel foam is highly versatile, making it suitable for a wide range of uses, from battery electrodes to heating materials in industrial equipment, thereby providing a comprehensive solution for various industries.

Excellent Thermal Management: The high thermal conductivity of nickel foam ensures efficient heat dissipation in critical applications, making it a reliable choice for high-temperature and high-performance systems.

Corrosion Resistance: Nickel foam’s inherent resistance to acid and alkali corrosion makes it durable even in harsh chemical environments, such as those found in chemical processing or exhaust gas purification systems.

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got ISO9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, Precision Alloy , FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

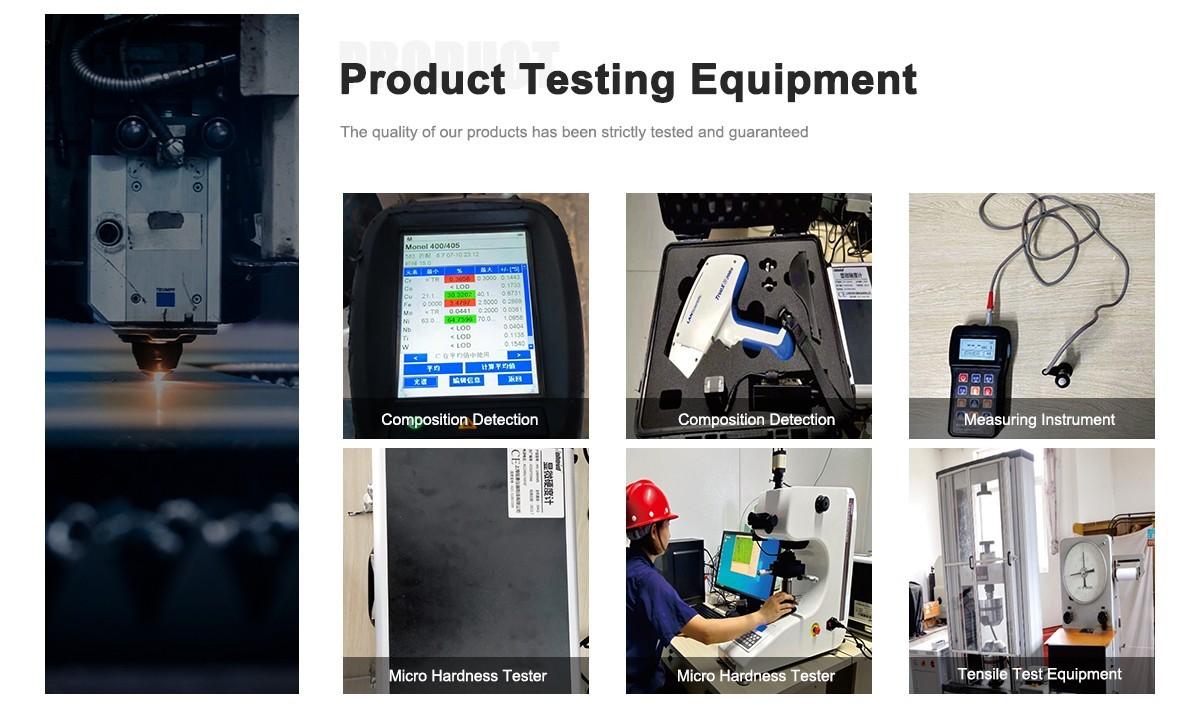

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

1. How soon can I expect a reply after sending an RFQ?

We typically provide quotes within 24 hours after receiving your inquiry. If you need an urgent response, please send a message via trade management or contact us directly by phone.

2. What is the delivery time for orders?

The delivery time depends on the order quantity. Generally, it takes around 20-30 days from order confirmation to shipment.

3. Do you accept OEM/ODM manufacturing?

Yes, we offer both OEM and ODM services. You can provide us with your samples or drawings, and we will manufacture according to your specifications.

4. Can I receive a catalogue of your products?

Yes, please contact us, and we will send you our catalogue by email for your review.

5. How do you ensure the quality of your products?

Our professional quality team ensures consistent product quality through advanced planning, strict execution, and continuous improvement. We conduct thorough quality checks during the production process.

6. Can you provide technical data and drawings for your products?

Yes, we can provide detailed technical data and drawings. Please specify the product you are interested in, and we will send the relevant information for your evaluation.