Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Nickel Foam

Product Details

Nickel foam is increasingly used in renewable energy applications, particularly in fuel cell technology, due to its exceptional properties such as high porosity, excellent thermal conductivity, and mechanical strength. Its open-cell structure enables efficient gas diffusion and fuel distribution, which are critical for enhancing fuel cell performance and energy conversion efficiency. Nickel foam is also durable, resistant to corrosion, and can withstand extreme operating conditions, making it a reliable choice for sustainable energy solutions.

This high-performance nickel foam material is ideal for use in a wide range of renewable energy applications, especially for fuel cells that require stable, high-efficiency performance over extended periods. It plays a crucial role in optimizing fuel cell efficiency, improving durability, and extending the operational life of renewable energy systems.

Material | Nickel foam, Sold in sheet |

Dimension | 500*1000, or customized as request |

Thickness | 0.5mm, 1.0mm, 1.5mm, 2.0mm,3.00mm etc |

The aperture | 80 PPI (5-80 PPI available) |

Porosity | 90-98% |

Through Hole Rate | ≥98% |

Bulk density | 0.25-1.00g/cm3 |

Key Features:

High Porosity & Surface Area: Nickel foam provides a large surface area for electrochemical reactions, enhancing fuel cell performance.

Excellent Thermal Conductivity: Efficient heat transfer is vital for maintaining optimal fuel cell operation temperatures.

Corrosion Resistance: With a high resistance to corrosion, nickel foam ensures long-lasting performance in harsh environments.

Mechanical Strength: The material can withstand high mechanical stress and pressure without deformation, ensuring durability.

Recyclability: Nickel foam can be fully recycled, supporting eco-friendly and sustainable energy solutions.

Temperature Resistance: It performs well at temperatures exceeding 500°C, which is crucial for fuel cell environments.

Applications:

Fuel Cell Technology: Nickel foam is used in proton exchange membrane (PEM) and solid oxide fuel cells (SOFC) as an electrode support material for better gas distribution.

Hydrogen Production: Its excellent gas permeability makes it ideal for hydrogen fuel production systems, enhancing efficiency.

Renewable Energy Systems: Nickel foam is widely used in systems that integrate renewable energy sources, including solar and wind energy storage.

Electrochemical Applications: It is a critical component in various electrochemical processes where efficient energy conversion is required.

Advantages:

Enhanced Fuel Cell Efficiency: The high surface area and structural integrity of nickel foam allow for better gas flow and uniform distribution, improving fuel cell efficiency.

Durability: Nickel foam withstands aggressive fuel cell environments, including high temperatures and corrosive substances, making it ideal for long-term use.

Versatility in Renewable Technologies: The material can be applied across different renewable energy systems, offering adaptability and multi-application capabilities.

Sustainability: As a recyclable material, nickel foam contributes to a greener, more sustainable energy infrastructure.

Cost-Effective: By improving the efficiency and longevity of renewable systems, nickel foam can help reduce operational costs over time.

Packaging and Delivery:

Packaging: Nickel foam is securely packaged in eco-friendly materials to ensure safe delivery. Standard packaging includes individual sheets or rolls, and it can be customized per client specifications.

Delivery: Fast and reliable shipping options are available. Standard delivery typically takes 20-30 days depending on the order size. Expedited shipping is available for urgent requirements.

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got ISO9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, Precision Alloy , FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

FAQ:

Q1: How can I place an order for Nickel Foam?

A1: Simply contact us via email or through our website. Our customer support team will guide you through the order process.

Q2: What is the minimum order quantity for Nickel Foam?

A2: The minimum order quantity depends on the product specifications and your application. Contact us to discuss your specific needs.

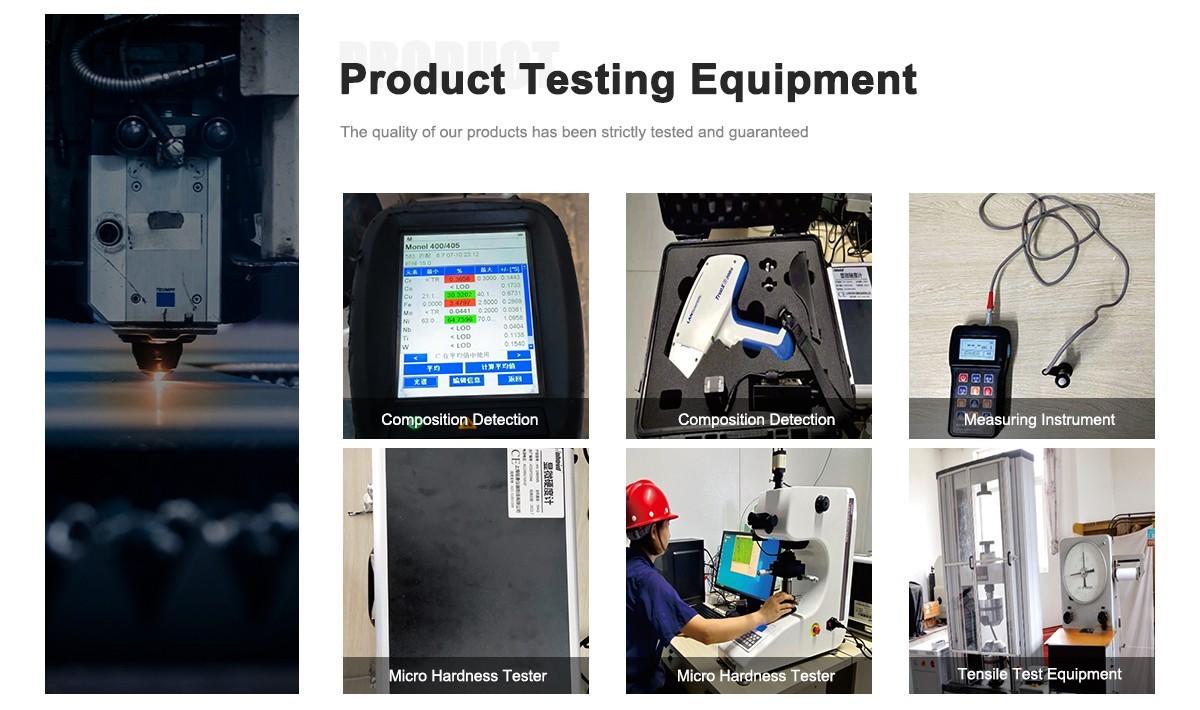

Q3: How is the quality of Nickel Foam ensured?

A3: We maintain a strict quality control process to ensure every batch meets international standards. All products are tested for mechanical strength, porosity, and corrosion resistance before shipment.

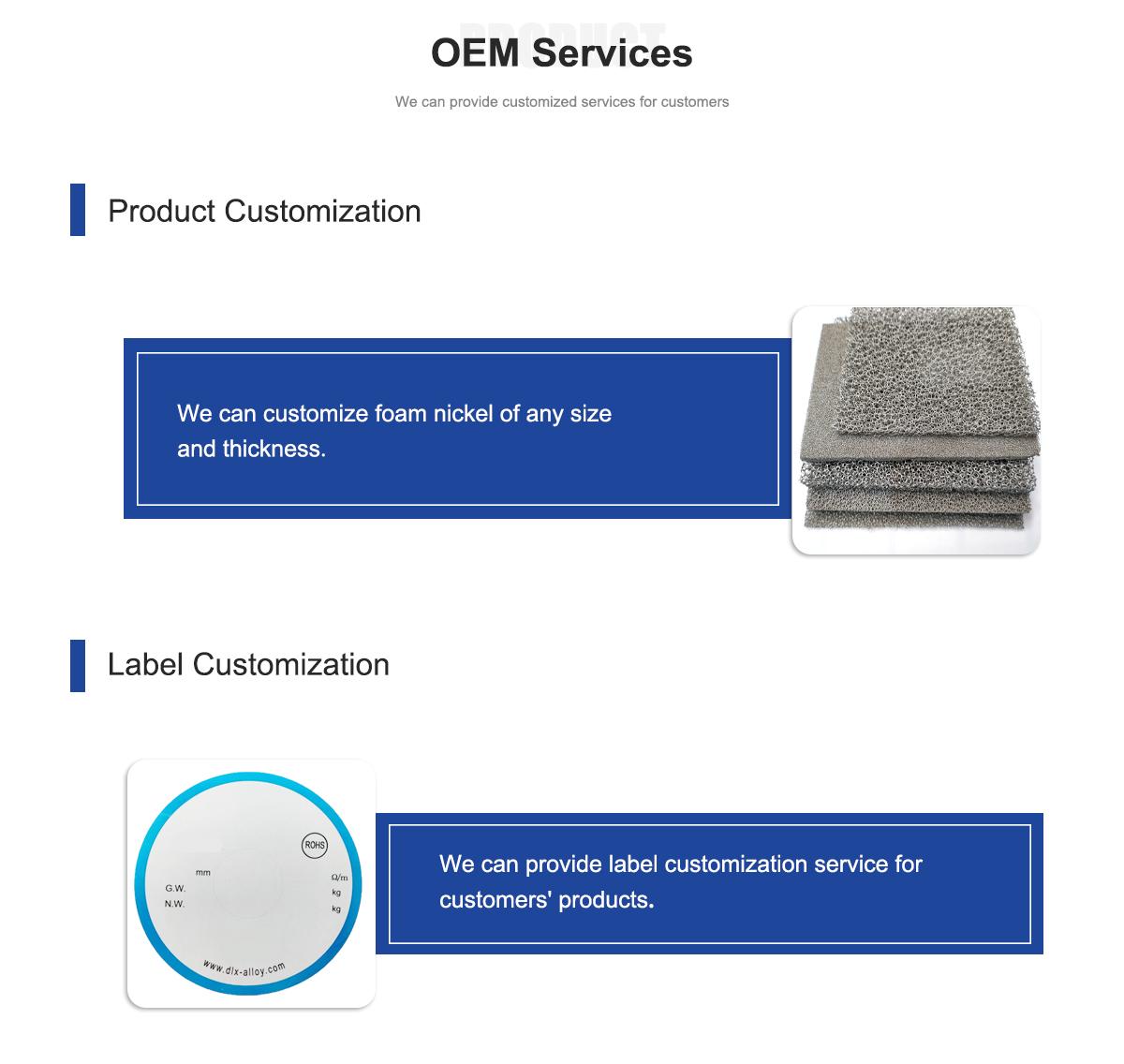

Q4: Can I customize the size and specifications of Nickel Foam?

A4: Yes, we offer customization options for various thicknesses, cell sizes, and porosity levels to meet the unique needs of your application.

Q5: How long does delivery take?

A5: Standard delivery takes 20-30 days, depending on the quantity. Expedited shipping options are available upon request.

Q6: How do I contact customer support for more information?

A6: You can reach us by email or through the contact form on our website. Our support team is available to assist you with any inquiries.