Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

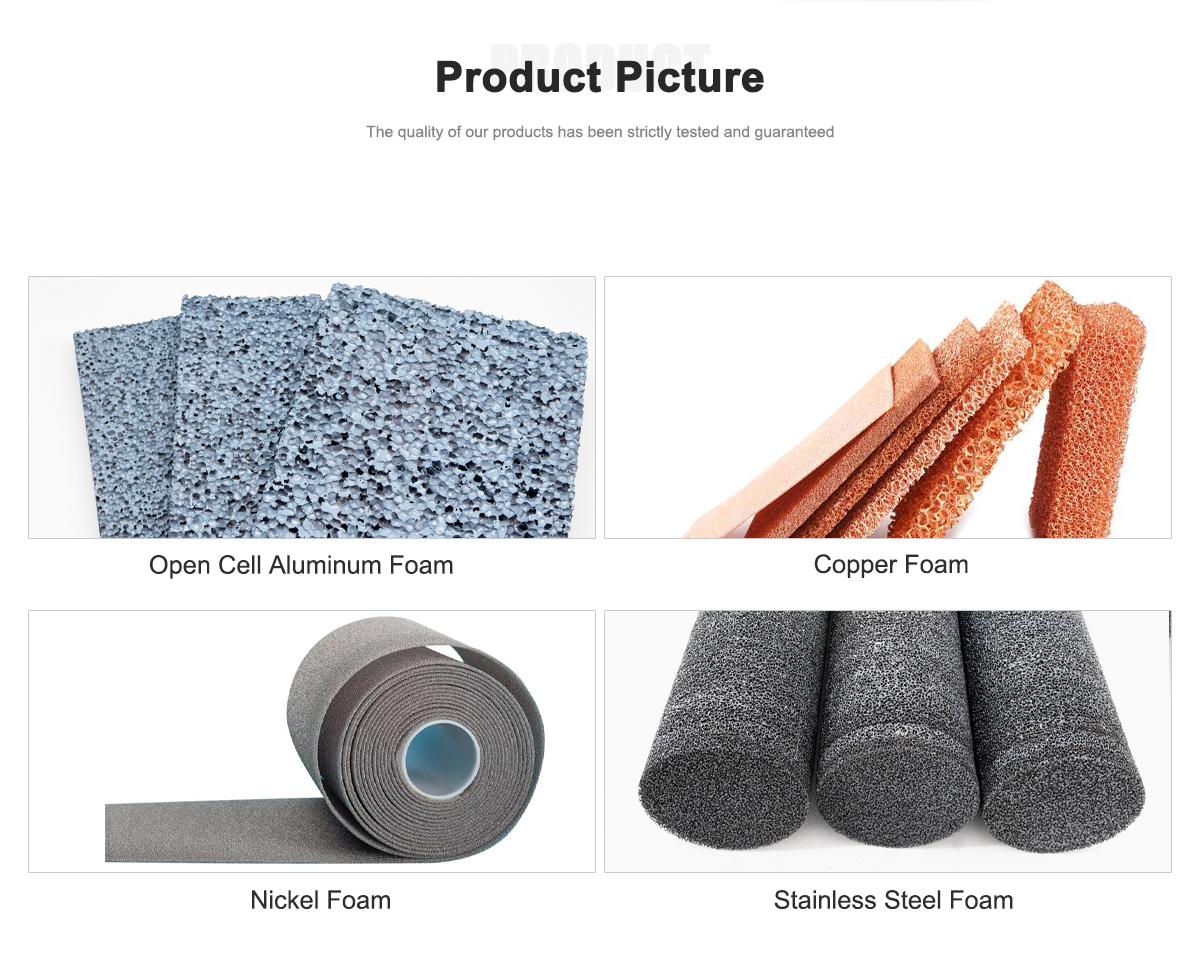

Nickel Foam

Product Details

Ultra-Porous Nickel Foam is a highly versatile material, recognized for its superior properties in a variety of industrial applications. With its unique three-dimensional structure, Nickel Foam offers exceptional performance in areas such as gas separation, sound insulation, and electromagnetic shielding. Known for its lightweight nature, high thermal conductivity, and excellent durability under extreme conditions, Nickel Foam is increasingly utilized in cutting-edge technologies, ranging from aerospace to energy systems.

Material | Nickel foam, Sold in sheet |

Dimension | 500*1000, or customized as request |

Thickness | 0.5mm, 1.0mm, 1.5mm, 2.0mm,3.00mm etc |

The aperture | 80 PPI (5-80 PPI available) |

Porosity | 90-98% |

Through Hole Rate | ≥98% |

Bulk density | 0.25-1.00g/cm3 |

Key Attributes:

Ultra-Light Quality: Nickel Foam boasts a specific surface area of 0.2~0.3, making it one of the lightest Metal Foams with a density 1/4 of water, 1/3 of wood, 1/10 of aluminum, and 1/30 of iron.

Sound Absorption: Its porous structure offers broad-frequency sound absorption capabilities, ensuring effective noise reduction across a range of applications.

Electron Wave Shielding: Nickel Foam effectively shields electromagnetic waves by approximately 90dB, offering excellent protection with minimal material thickness.

Thermal Conductivity: Nickel Foam’s high thermal conductivity ensures efficient heat transfer in applications like heat exchangers, and its uniform pore structure enhances its flow stability.

Recyclable: Nickel Foam is fully recyclable, making it an environmentally friendly material choice for sustainable manufacturing.

Fire Resistance & High-Temperature Resistance: The material is stable under high temperatures, capable of resisting heat above 1100°C, making it ideal for high-performance applications in harsh environments.

Applications:

Gas Separation & Filtration: Ideal for use in advanced gas separation technologies and fluid filtration systems, ensuring enhanced efficiency in gas flow and separation processes.

Sound Insulation: Utilized in noise-sensitive areas like automotive, aerospace, and construction, providing high-performance sound insulation.

Electromagnetic Shielding: Used in the electronics industry for shielding against electromagnetic interference (EMI), protecting sensitive equipment.

Aerospace & Energy Systems: With its high-temperature resistance and thermal conductivity, Nickel Foam is perfect for use in aerospace systems, energy applications, and industrial furnaces.

Environmental & Industrial Filtration Systems: Nickel Foam’s filtering ability and thermal conductivity make it suitable for high-flow filtration in harsh chemical environments, such as chemical processing plants.

Advantages of Ultra-Porous Nickel Foam:

Superior Gas Separation Efficiency: The advanced structure ensures efficient filtration and separation, even in challenging applications.

Excellent Durability: Resistant to high temperatures, chemicals, and corrosion, ensuring longevity in extreme conditions.

High Thermal and Acoustic Performance: Provides excellent thermal management and sound absorption capabilities.

Recyclable and Sustainable: Fully recyclable, making it a sustainable material choice for companies focused on reducing environmental impact.

Customization Flexibility: Can be easily fabricated to meet specific application needs, offering versatility in design and function.

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got ISO9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, Precision Alloy , FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

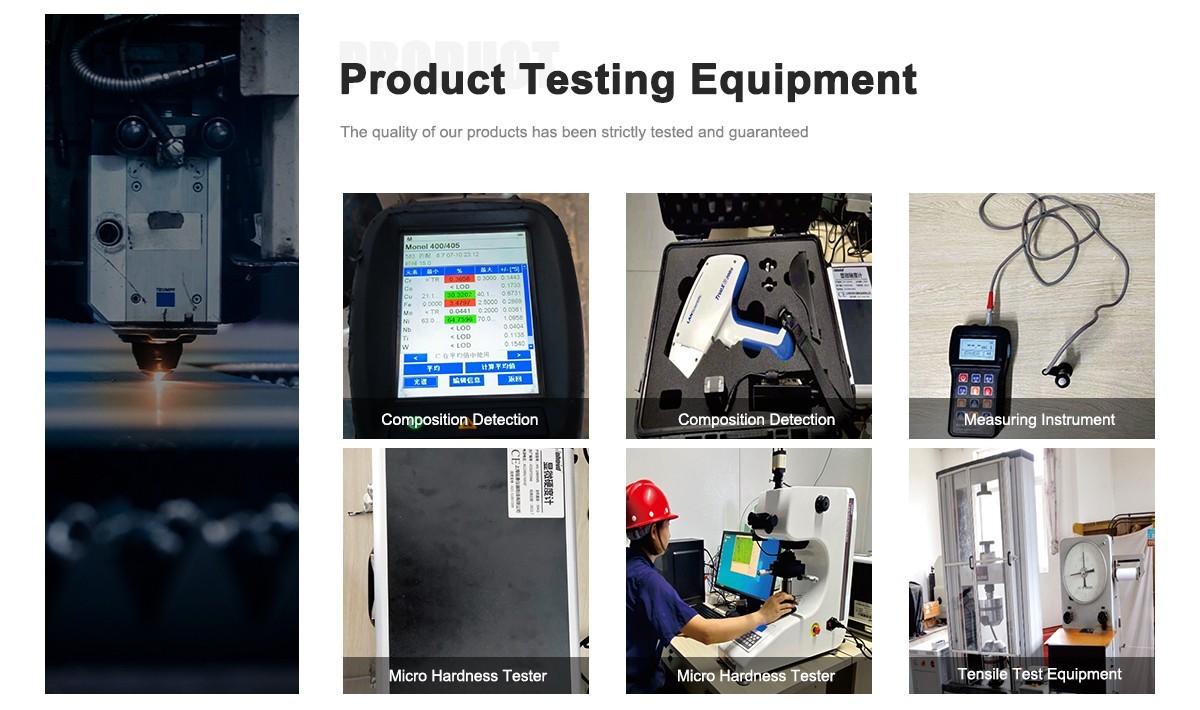

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

FAQ

Q: When can I expect a response after sending an RFQ?

A: We typically respond within 24 hours. If you need an urgent quote, please reach out through trade management or call us directly.

Q: What is the delivery time for orders?

A: Delivery time depends on the order quantity but usually takes 20-30 days.

Q: Do you accept OEM/ODM manufacturing?

A: Yes, we accept OEM/ODM manufacturing. You can provide us with samples or drawings for customization.

Q: Can you send me your product catalog?

A: Yes, please contact us, and we’ll send our catalog via email.

Q: How do you ensure product quality?

A: Our professional quality team ensures product quality through advanced planning, strict implementation, and continuous improvement, ensuring consistent high standards.

Q: Can you provide technical data and drawings for specific products?

A: Yes, we can provide detailed technical data and drawings. Just let us know the product and its applications, and we will send the required information for your review.