Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Hastelloy Alloys

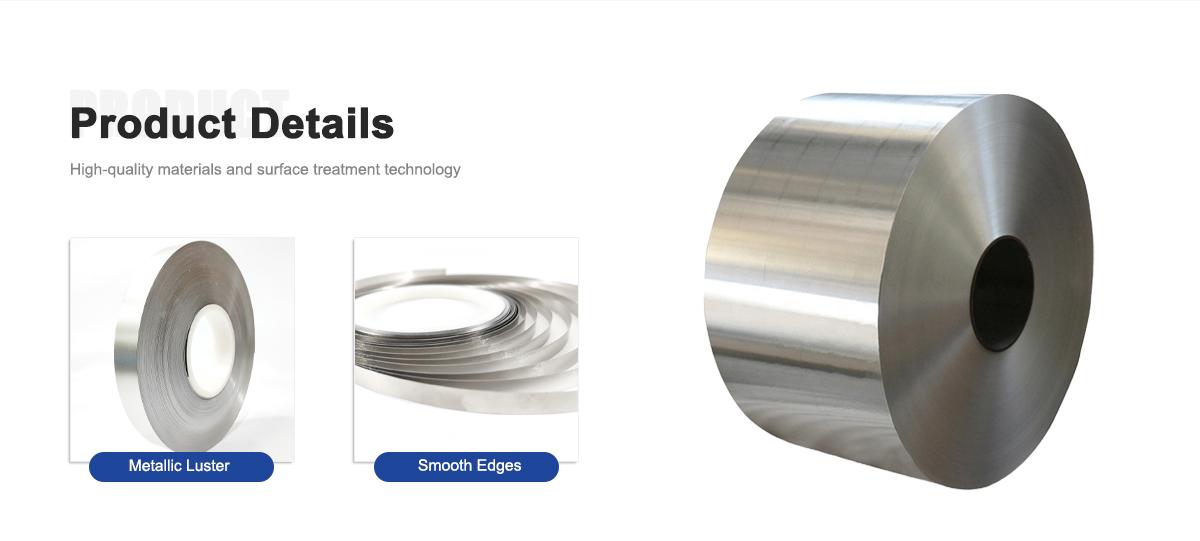

Product Details

https://www.youtube.com/embed/0xy_zwVLXho?si=xDquazBX8ClBhFFS

Hastelloy alloy strip refers to thin, flat-rolled forms of Hastelloy nickel-based superalloys, renowned for their exceptional resistance to corrosion, pitting, and stress-corrosion cracking. Specifically, Hastelloy C276 strip and Hastelloy C22 strip are austenitic nickel-molybdenum-chromium alloys designed for extreme environments. These corrosion-resistant Hastelloy strips are widely used in chemical processing industries for handling aggressive acids and in pollution control systems to combat emissions and effluents.

The versatility of Hastelloy alloy strip C276 & C22 makes it indispensable for fabricating components like scrubbers, heat exchangers, and ducts. By choosing DLX Alloy's Hastelloy strip for chemical processing and pollution control, you benefit from materials that withstand temperatures from cryogenic levels up to 750°F (400°C) while maintaining structural integrity.

Our Hastelloy Alloy Strip C276 & C22 stand out for their robust properties in high temperature and reducing acid applications:

Resistant to pitting, crevice corrosion, and stress corrosion cracking, especially in chloride-containing environments.

Maintains mechanical strength and resists oxidation at elevated temperatures, making it suitable for high-temperature applications.

Easily weldable without losing corrosion resistance, allowing for versatile fabrication options.

Highly malleable, enabling it to be formed into complex shapes without compromising strength.

Effective in resisting oxidation in both reducing and oxidizing environments.

Exhibits high mechanical strength, ensuring reliability in demanding applications.

Suitable for a wide range of applications, including chemical processing, oil and gas, and power generation.

Does not become sensitized during welding, maintaining its protective properties even after fabrication.

| Hastelloy Grade | Hastelloy B | Hastelloy C-276 | Hastelloy C-4 | Hastelloy C-22 | Hastelloy C-59 | Hastelloy G | Hastelloy X |

| Corresponding brand | N10001/ NS321/ ONl65Mo28Fe5/ VN12MV | N10276 / 2.4819/ NS334 / CW12MW | N06455 / 2.4610I 00Cr16Ni65Mo16Ti / NS335 | N06022 / 2.4602/ NS3308 | N06059 / 2.4605/ NS3311 / Alloy59 | N06007 / 2.4618/ NS3402 | N06002 / 2.4665/ GH3536 / GH32 |

| Chemical composition% | |||||||

| C≤ | 0.05 | 0.01 | 0.015 | 0.015 | 0.01 | 0.05 | 0.05-0.15 |

| Mn≤ | 1 | 1 | 1 | 0.5 | 0.5 | 1.0-2.0 | 1 |

| P≤ | 0.04 | 0.04 | 0.04 | 0.02 | 0.015 | 0.04 | 0.04 |

| S≤ | 0.03 | 0.03 | 0.03 | 0.02 | 0.01 | 0.03 | 0.03 |

| Si≤ | 1 | 0.08 | 0.08 | 0.08 | 0.01 | 1 | 1 |

| Cr≤ | ≤1 | 14.5-16.5 | 14.0-18.0 | 14.0-18.0 | 22.0-24.0 | 21.0-23.5 | 20.5-23.0 |

| Ni≤ | the base | the base | the base | the base | the base | the base | the base |

| Mo | 26.0-30.0 | 15.0-17.0 | 14.0-17.0 | 12.5-14.5 | 15.0-16.5 | 5.5-7.5 | 8.0-10.0 |

| Cu | ≤0.50 | 1.5-2.5 | |||||

| N | W:3.0-4.5 | W:2.5-3.5 | W:≤1.0 | W:0.2-1.0 | |||

| Nb | 1.75-2.50 | ||||||

| Other | V:0.20-0.40 Co:≤2.50 Fe:4.0-60. | V:≤0.35 Co:≤2.50 Fe:4.0-7.0 | Ti:≤0.70 Co:≤2.0 Fe:≤3.0 | V:≤0.35 Co:≤2.5 Fe:2.0-6.0 | AI:0.10-0.40 Co:≤0.30 Fe:≤1.50 | Co:≤2.5 Fe:≤18.0-21.0 | Co:≤0.5-2.5 Fe:≤17.0-20.0 |

Hastelloy strip materials like Hastelloy C276 strip and Hastelloy C22 strip are essential in industries requiring robust corrosion protection:

Used in reactors, heat exchangers, and piping systems handling aggressive chemicals, including acids and chlorides.

Employed in downhole tubing, valves, and other components exposed to corrosive environments, such as sour gas and seawater.

Utilized in flue gas desulfurization systems and other equipment designed to manage and reduce emissions.

Applied in components that require high strength and resistance to extreme temperatures and corrosive environments.

Used in equipment that must maintain purity and resist contamination from corrosive substances.

Suitable for components in marine environments, such as shipbuilding and offshore platforms, due to its resistance to seawater corrosion.

Employed in nuclear reactors and fossil fuel power plants, where high temperatures and corrosive conditions are prevalent.

Used in equipment that requires high sanitary standards and resistance to corrosive cleaning agents.

Ideal for manufacturing tanks and containers for storing corrosive chemicals, ensuring long-term durability.

These applications highlight the versatility and reliability of Hastelloy alloy wire in challenging environments across various industries.

Founded in 2002, CHANGZHOU DLX ALLOY CO., LTD is a leading manufacturer specializing in the research and production of specialized alloy materials. Our factory has earned both the ISO9001 International Quality Management System Certificate and SGS Certification, affirming our commitment to high standards of quality.

We are experts in the entire alloy production process, including melting, drawing, heat treatment, finishing, and rigorous testing. Our product range includes nickel-based, copper-based, and iron-based alloys, such as super alloys, welding materials, anti-corrosion alloys, precision alloys, FeCrAl alloys, NiCr alloys, CuNi alloys, and thermocouples. These are available in various forms including wire, strip, ribbon, bar, tube, and plate.

Q:What is your working time?

A:Monday-Saturday : 7:30AM-17:00PM (Beijing time, GMT+08.00)

Q:Do you provide free samples?

A:Yes, we can provide a free sample for testing,buyer should bear all the shipping costs.

Q:What is your payment terms?

A:T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

Q:What is the lead time?

A:Usually sample lead time is 7 days after payment has been confirmed.