Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Hastelloy Alloys

Product Details

Hastelloy Tube is a nickel-base alloy product known for its exceptional versatility and resistance to a wide range of corrosive chemicals. As a premier supplier of advanced nickel-base alloys, we specialize in providing top-tier Hastelloy pipe and Hastelloy tube solutions for the world's most challenging environments. Our high-performance Hastelloy pipes and tubes, including the industry-standard Hastelloy C276 tube, are engineered for unparalleled corrosion resistance, exceptional strength, and long-term reliability in aggressive conditions. We supply seamless pipe and tube products that meet the strictest dimensional and quality standards.

Why Choose Our Hastelloy Pipes & Tubes?

Our Hastelloy pipe and Hastelloy tube products are the go-to choice for engineers and fabricators who cannot compromise on material integrity. The Hastelloy C276 tube, in particular, offers exceptional corrosion resistance against a wide range of corrosive media, including sulfuric acid, hydrochloric acid, chlorine gas, and solvents.

Excellent Corrosion Resistance: Handles both oxidizing and reducing agents.

Versatile Alloy Grades: We offer various Hastelloy grades, including C276, C22, B2, and B3, to match your specific corrosion challenge.

Robust Seamless Pipe Design: Ideal for critical applications in oil & gas, chemical processing, and power generation.

Long Service Life: Reduces maintenance costs and downtime, providing a superior lifetime value.

High-Performance Nickel-Base Alloy: The nickel-chromium-molybdenum-tungsten composition of Hastelloy C276 tube is the benchmark for reliability.

| Hastelloy Grade | Hastelloy B | Hastelloy C-276 | Hastelloy C-4 | Hastelloy C-22 | Hastelloy C-59 | Hastelloy G | Hastelloy X |

| Corresponding brand | N10001/ NS321/ ONl65Mo28Fe5/ VN12MV | N10276 / 2.4819/ NS334 / CW12MW | N06455 / 2.4610I 00Cr16Ni65Mo16Ti / NS335 | N06022 / 2.4602/ NS3308 | N06059 / 2.4605/ NS3311 / Alloy59 | N06007 / 2.4618/ NS3402 | N06002 / 2.4665/ GH3536 / GH32 |

| Chemical composition% | |||||||

| C≤ | 0.05 | 0.01 | 0.015 | 0.015 | 0.01 | 0.05 | 0.05-0.15 |

| Mn≤ | 1 | 1 | 1 | 0.5 | 0.5 | 1.0-2.0 | 1 |

| P≤ | 0.04 | 0.04 | 0.04 | 0.02 | 0.015 | 0.04 | 0.04 |

| S≤ | 0.03 | 0.03 | 0.03 | 0.02 | 0.01 | 0.03 | 0.03 |

| Si≤ | 1 | 0.08 | 0.08 | 0.08 | 0.01 | 1 | 1 |

| Cr≤ | ≤1 | 14.5-16.5 | 14.0-18.0 | 14.0-18.0 | 22.0-24.0 | 21.0-23.5 | 20.5-23.0 |

| Ni≤ | the base | the base | the base | the base | the base | the base | the base |

| Mo | 26.0-30.0 | 15.0-17.0 | 14.0-17.0 | 12.5-14.5 | 15.0-16.5 | 5.5-7.5 | 8.0-10.0 |

| Cu | ≤0.50 | 1.5-2.5 | |||||

| N | W:3.0-4.5 | W:2.5-3.5 | W:≤1.0 | W:0.2-1.0 | |||

| Nb | 1.75-2.50 | ||||||

| Other | V:0.20-0.40 Co:≤2.50 Fe:4.0-60. | V:≤0.35 Co:≤2.50 Fe:4.0-7.0 | Ti:≤0.70 Co:≤2.0 Fe:≤3.0 | V:≤0.35 Co:≤2.5 Fe:2.0-6.0 | AI:0.10-0.40 Co:≤0.30 Fe:≤1.50 | Co:≤2.5 Fe:≤18.0-21.0 | Co:≤0.5-2.5 Fe:≤17.0-20.0 |

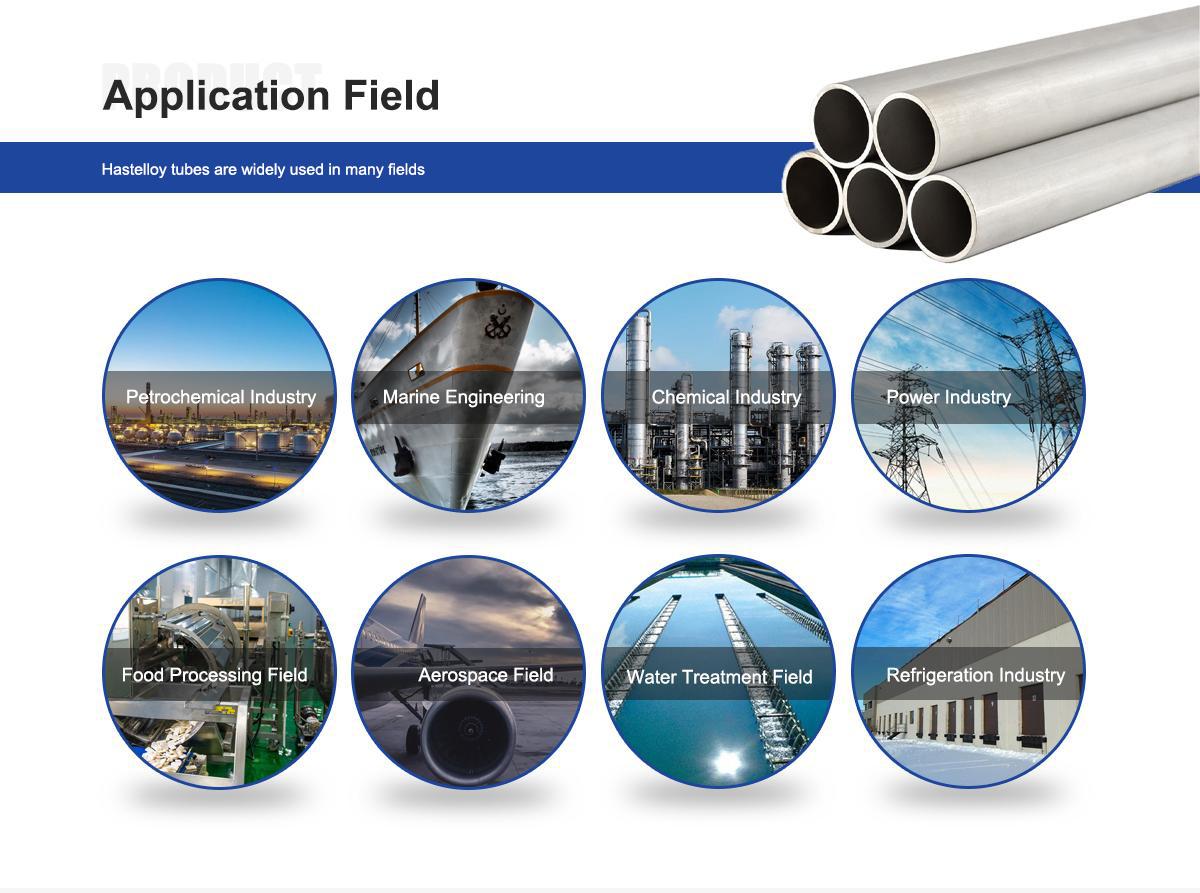

The superior properties of Hastelloy Tube make it indispensable across a wide range of sectors. As a trusted supplier, we provide solutions for:

Used in reactors, heat exchangers, piping systems, and vessels handling aggressive acids, chlorides, and catalysts. Hastelloy C276 Tube is essential for safe and efficient chemical production.

Ideal for flue gas desulfurization systems, scrubbers, and waste incineration equipment where resistance to sulfur compounds and chlorides is critical.

Employed in process equipment where high purity and resistance to corrosive cleaning agents and process streams are required.

Used in critical components for refining processes that involve corrosive sour gas and acidic conditions.

Applied in digesters, bleach plants, and other equipment exposed to corrosive chlorine compounds and acidic liquors.

Founded in 2002, CHANGZHOU DLX ALLOY CO., LTD is a leading manufacturer specializing in the research and production of specialized alloy materials. Our factory has earned both the ISO9001 International Quality Management System Certificate and SGS Certification, affirming our commitment to high standards of quality.

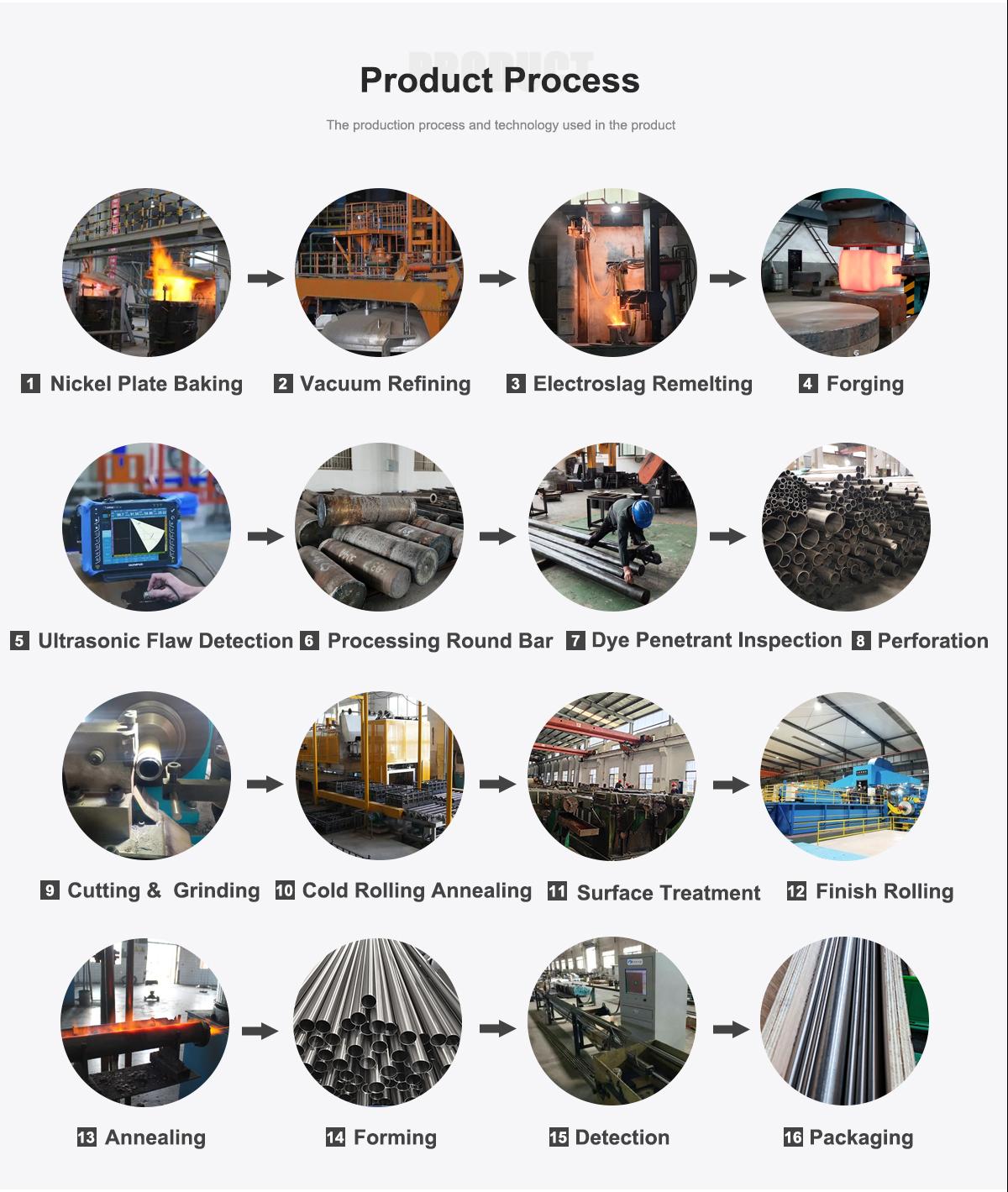

We are experts in the entire alloy production process, including melting, drawing, heat treatment, finishing, and rigorous testing. Our product range includes nickel-based, copper-based, and iron-based alloys, such as super alloys, welding materials, anti-corrosion alloys, precision alloys, FeCrAl alloys, NiCr alloys, CuNi alloys, and thermocouples. These are available in various forms including wire, strip, ribbon, bar, tube, and plate.

Q:What is your working time?

A:Monday-Saturday : 7:30AM-17:00PM (Beijing time, GMT+08.00)

Q:Do you provide free samples?

A:Yes, we can provide a free sample for testing,buyer should bear all the shipping costs.

Q:What is your payment terms?

A:T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

Q:What is the lead time?

A:Usually sample lead time is 7 days after payment has been confirmed.