Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Hastelloy Alloys

Product Details

Hastelloy C276 bars are premium alloys known for their exceptional resistance to a broad range of corrosive environments and high-temperature conditions. Composed of a unique combination of nickel, molybdenum, chromium, and tungsten, this alloy is engineered to withstand severe operating conditions, including exposure to aggressive acids, high temperatures, and stress corrosion. Due to its versatility and durability, Hastelloy C276 is widely used across industries such as chemical processing, oil and gas, marine, and pollution control.

item | HC-276 | C-22 | C-4 | B2 | B3 | N |

C | ≤0.01 | ≤0.015 | ≤0.015 | ≤0.02 | ≤0.01 | 0.04-0.08 |

Mn | ≤1 | ≤0.5 | ≤1 | ≤1 | ≤3 | ≤1 |

Fe | 4-7 | 2-6 | ≤3 | ≤2 | ≤1.5 | ≤5 |

P | ≤0.04 | ≤0.02 | ≤0.04 | ≤0.04 | -- | ≤0.015 |

S | ≤0.03 | ≤0.02 | ≤0.03 | ≤0.03 | -- | ≤0.02 |

Si | ≤0.08 | ≤0.08 | ≤0.08 | ≤0.1 | ≤0.1 | ≤1 |

Ni | rest | rest | rest | rest | ≤65 | rest |

Co | ≤2.5 | ≤2.5 | ≤2 | ≤1 | ≤3 | ≤0.2 |

Ti+Cu | -- | -- | ≤0.7 | -- | ≤0.4 | ≤0.35 |

Al+Ti | -- | -- | -- | -- | ≤0.5 | ≤0.5 |

Cr | 14.5-16.5 | 20-22.5 | 14-18 | ≤1 | ≤1.5 | 6-8 |

Mo | 15-17 | 12.5-14.5 | 14-17 | 26-30 | ≤28.5 | 15-18 |

B | -- | -- | -- | -- | -- | ≤0.01 |

W | 3-4.5 | 2.5-3.5 | -- | -- | ≤3 | ≤0.5 |

V | ≤0.35 | ≤0.35 | -- | 0.2-0.4 | -- | ≤0.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

Outstanding Corrosion Resistance: The high nickel content, combined with molybdenum and chromium, gives Hastelloy C276 superior resistance to aggressive chemicals like sulfuric acid, hydrochloric acid, and chlorine. It also performs well in reducing and oxidizing environments, making it suitable for a wide array of industrial applications.

High-Temperature Stability: Hastelloy C276 retains its mechanical properties and corrosion resistance even at elevated temperatures up to 1,900°F (1,038°C). This heat resistance makes it ideal for applications in power generation, chemical processing, and marine environments.

Robust Mechanical Properties: Known for its high strength and toughness, Hastelloy C276 can withstand significant stress and pressure. This makes it an excellent material for critical components that require reliability in harsh environments.

Resistance to Pitting & Stress Corrosion Cracking: Its exceptional resistance to localized corrosion, such as pitting and crevice corrosion, ensures that Hastelloy C276 can perform reliably in environments that are typically hostile to other materials.

Ease of Fabrication: Despite its strength and resistance, Hastelloy C276 is easy to fabricate and can be processed into various forms, such as bars, sheets, and pipes, using conventional methods like welding and forming.

Hastelloy C276 bars are widely used across several industries due to their unique properties. Some of the most common applications include:

Chemical Processing Industry:

Used in reactors, heat exchangers, and tanks where highly corrosive chemicals such as sulfuric and hydrochloric acids are processed.

Ideal for environments with frequent exposure to harsh chemicals.

Oil and Gas Industry:

Utilized in valves, pumps, and pipelines, especially in sour gas environments and under high pressure.

Excellent performance in corrosive fluids and gases encountered in upstream and downstream applications.

Marine Applications:

Commonly used for seawater systems, such as pumps, valves, and heat exchangers.

Its resistance to seawater and brine makes it an optimal choice for offshore platforms and naval applications.

Pollution Control:

Applied in flue gas desulfurization systems, scrubbers, and stack liners, where exposure to acidic gases and high temperatures is common.

Ensures long-lasting performance in harsh, abrasive conditions.

Power Generation:

Employed in geothermal, nuclear, and coal-fired power plants, where components are exposed to high temperatures and corrosive conditions.

Used for heat exchangers, superheater tubes, and reheater tubes.

Pulp and Paper Industry:

Used in digesters, bleaching vessels, and other equipment exposed to acidic and chloride-containing environments.

Offers superior corrosion resistance to the aggressive chemicals used in paper production.

Pharmaceutical Industry:

Applied in reactors, mixers, and piping systems that require high levels of cleanliness and resistance to corrosion.

Ideal for handling aggressive pharmaceutical intermediates.

Aerospace Industry:

Employed in components that need high strength and corrosion resistance at elevated temperatures.

Suitable for harsh aerospace environments, including aircraft engines and exhaust systems.

Waste Treatment:

Used in waste incinerators, storage tanks, and equipment handling corrosive chemicals.

Ensures long-term performance and reliability in waste processing applications.

Hastelloy C276 bars possess several physical and mechanical properties that make them ideal for extreme conditions. Here is a quick look at their key characteristics:

Density: 8.89 g/cm³ – A high density due to its alloying elements.

Melting Point: 1325-1370°C – Suitable for high-temperature applications.

Tensile Strength: 690 MPa (min) – High tensile strength allows the material to withstand heavy loads.

Yield Strength: 283 MPa (min) – The stress at which the material deforms plastically.

Elongation: 40% – Indicates high ductility, allowing the material to bend without breaking.

Hardness (Rockwell B): 85 (max) – Moderate hardness suitable for industrial applications.

Modulus of Elasticity: 205 GPa – Indicates stiffness; high modulus means the material is rigid.

Thermal Conductivity: 10.2 W/m·K – Lower thermal conductivity due to the alloy’s composition.

Electrical Resistivity: 1.28 µΩ·m – High resistivity, typical of alloys with nickel and chromium.

Hastelloy C276 bars stand out as a top choice for applications where both high strength and superior corrosion resistance are crucial. Whether it's exposure to harsh chemicals, high-temperature environments, or high-pressure systems, Hastelloy C276 provides unmatched durability and reliability.

Unmatched Corrosion Resistance: The combination of nickel, molybdenum, chromium, and tungsten ensures resistance to the most aggressive corrosive media.

High-Temperature Stability: Ideal for high-temperature processes and environments, ensuring that your equipment remains operational under extreme conditions.

Versatility: Suitable for a wide range of industries, from chemical processing to aerospace, offering flexibility in design and application.

Ease of Fabrication: Can be easily fabricated into various forms for customized applications.

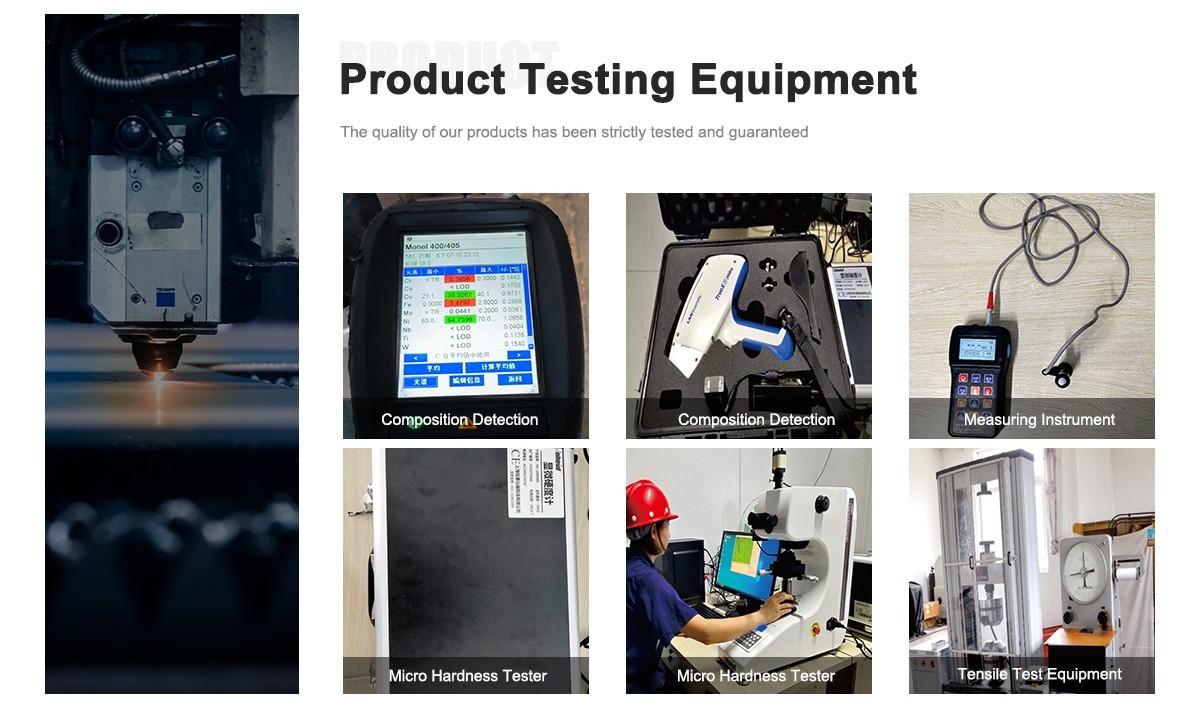

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got ISO9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, Precision Alloy , FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

1. What industries use Hastelloy C276 bars?

Hastelloy C276 bars are widely used in industries such as chemical processing, oil & gas, marine, power generation, and pollution control, thanks to their excellent corrosion resistance and high-temperature stability.

2. What are the key properties of Hastelloy C276 bars?

Hastelloy C276 offers outstanding resistance to corrosion, high mechanical strength, and high-temperature stability. It can withstand temperatures up to 1,900°F (1,038°C) and is resistant to a wide range of aggressive chemicals.

3. Can Hastelloy C276 bars be welded?

Yes, Hastelloy C276 bars are highly weldable and can be fabricated using conventional welding techniques, making them versatile for various industrial applications.

4. How long does Hastelloy C276 last in corrosive environments?

Hastelloy C276 provides excellent long-term performance in corrosive environments, offering extended service life even under severe conditions.

5. How can I purchase Hastelloy C276 bars?

To inquire about purchasing Hastelloy C276 bars or for more information, please contact us at DLX Alloy. We provide competitive pricing and expert customer support.