Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Hastelloy Alloys

Product Details

Hastelloy C276 plate is a high-performance, corrosion-resistant material designed to withstand extreme environmental conditions. Known for its superior resistance to a wide range of corrosive environments, this alloy is an excellent choice for industries that demand exceptional performance in high-temperature and aggressive chemical settings. Made from UNS N10276, Hastelloy C276 plate is often used in applications such as chemical processing, pollution control, and heat exchangers due to its ability to resist both oxidizing and reducing environments.

item | HC-276 | C-22 | C-4 | B2 | B3 | N |

C | ≤0.01 | ≤0.015 | ≤0.015 | ≤0.02 | ≤0.01 | 0.04-0.08 |

Mn | ≤1 | ≤0.5 | ≤1 | ≤1 | ≤3 | ≤1 |

Fe | 4-7 | 2-6 | ≤3 | ≤2 | ≤1.5 | ≤5 |

P | ≤0.04 | ≤0.02 | ≤0.04 | ≤0.04 | -- | ≤0.015 |

S | ≤0.03 | ≤0.02 | ≤0.03 | ≤0.03 | -- | ≤0.02 |

Si | ≤0.08 | ≤0.08 | ≤0.08 | ≤0.1 | ≤0.1 | ≤1 |

Ni | rest | rest | rest | rest | ≤65 | rest |

Co | ≤2.5 | ≤2.5 | ≤2 | ≤1 | ≤3 | ≤0.2 |

Ti+Cu | -- | -- | ≤0.7 | -- | ≤0.4 | ≤0.35 |

Al+Ti | -- | -- | -- | -- | ≤0.5 | ≤0.5 |

Cr | 14.5-16.5 | 20-22.5 | 14-18 | ≤1 | ≤1.5 | 6-8 |

Mo | 15-17 | 12.5-14.5 | 14-17 | 26-30 | ≤28.5 | 15-18 |

B | -- | -- | -- | -- | -- | ≤0.01 |

W | 3-4.5 | 2.5-3.5 | -- | -- | ≤3 | ≤0.5 |

V | ≤0.35 | ≤0.35 | -- | 0.2-0.4 | -- | ≤0.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

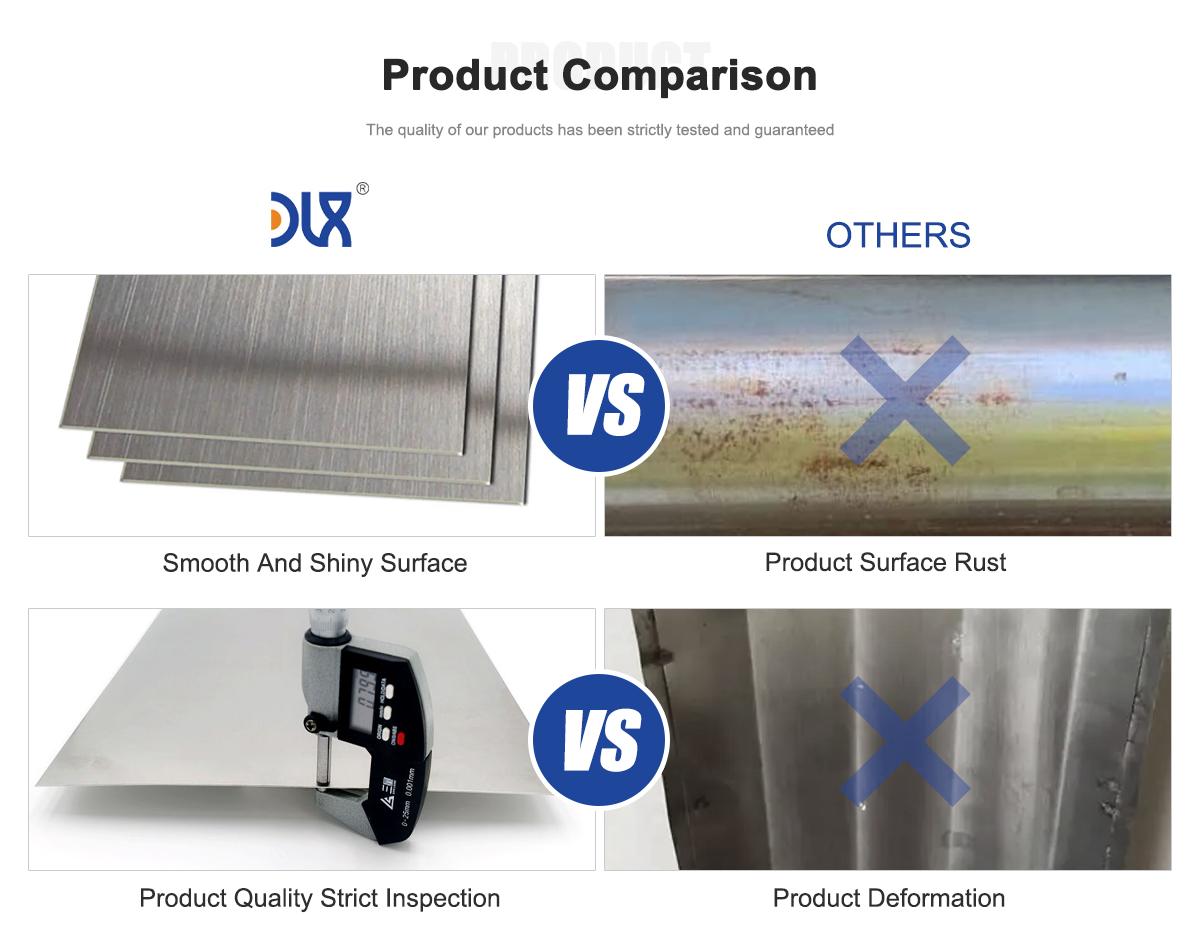

Corrosion Resistance: Hastelloy C276 plate is renowned for its resistance to many corrosive chemicals, including sulfuric acid, hydrochloric acid, chlorine, and other aggressive media. It excels in both oxidizing and reducing environments, providing unmatched protection against corrosion, pitting, and crevice corrosion.

High-Temperature Stability: This alloy can withstand temperatures up to 1,900°F (1,038°C), making it ideal for high-temperature applications where other alloys would typically degrade. Its thermal stability ensures reliable performance in challenging conditions.

Durability and Strength: Hastelloy C276’s excellent mechanical properties, including high strength and toughness, make it highly durable in harsh environments. The alloy maintains its integrity under mechanical stress, ensuring long service life and reduced maintenance.

Versatility in Application: Available in various surface finishes such as 2B, BA, and others, the plate is suitable for a wide range of industrial uses, from chemical reactors to marine applications, all while offering ease of fabrication.

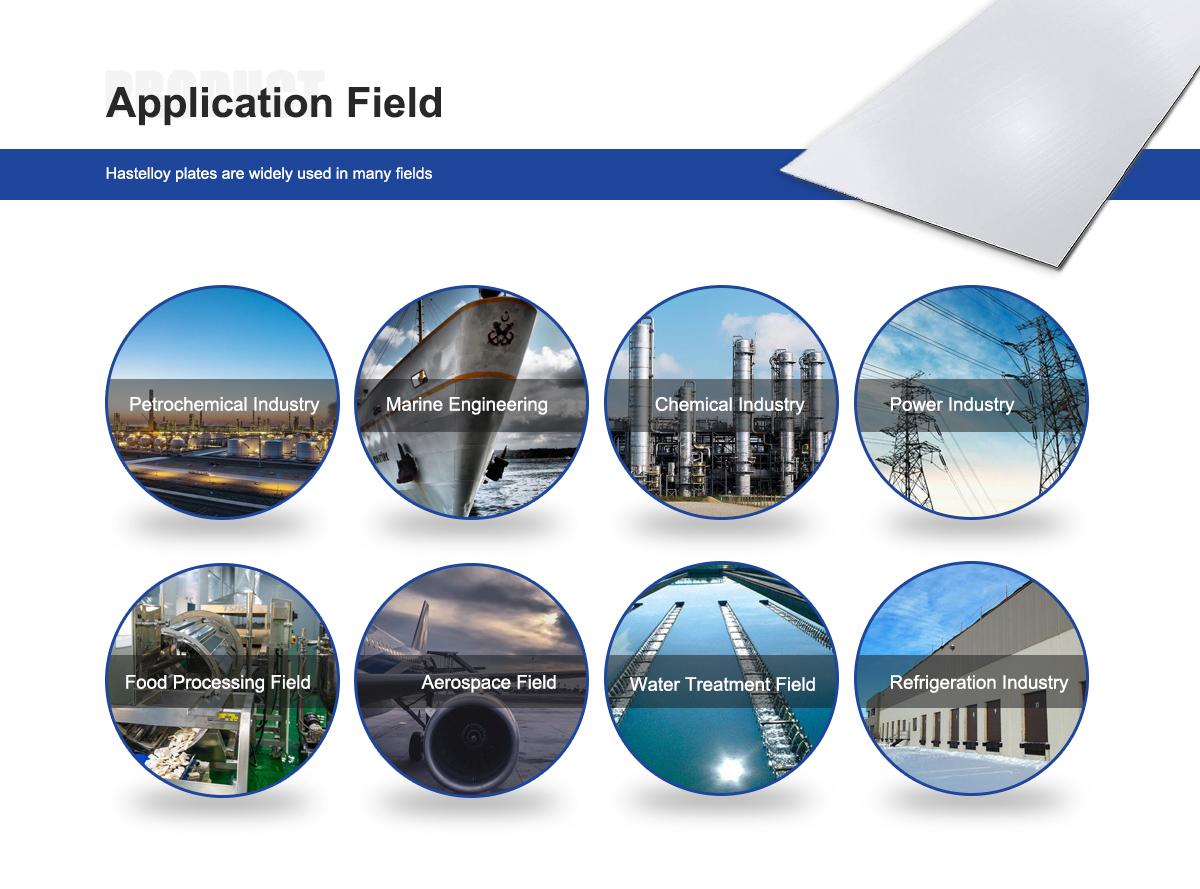

Hastelloy C276 is used in numerous industries where superior corrosion resistance and high-temperature stability are essential. Its key applications include:

Chemical Processing:

Ideal for use in reactors, heat exchangers, distillation columns, and other processing equipment exposed to highly corrosive chemicals like sulfuric acid, hydrochloric acid, and chlorine.

Pollution Control:

Commonly applied in flue gas desulfurization systems, scrubbers, and ducts to resist acidic gases, high temperatures, and abrasive environments.

Marine Industry:

Due to its excellent resistance to seawater corrosion, Hastelloy C276 plate is widely used in marine environments for components like pumps, valves, and heat exchangers.

Oil & Gas:

Used in sour gas environments, downhole tubing, and casing, where corrosion resistance to acidic gases and fluids is essential.

Power Generation:

Employed in geothermal, nuclear, and coal-fired power plants for components exposed to high temperatures and corrosive environments.

Aerospace:

Hastelloy C276 plate is used for engine parts and other critical components that require resistance to both corrosion and high temperatures.

Pharmaceutical and Food Processing:

Ideal for reactors, mixers, and piping systems, where cleanliness and resistance to corrosion are paramount.

The Hastelloy C276 plate is available in various dimensions and surface finishes to meet the specific requirements of different industries:

Surface Finishes: 2B, BA, No.1, No.4, No.8, HL, 8K, Mirror Finish

Dimensions: Available in widths ranging from 1000mm to 2500mm and thicknesses from 0.5mm to 50mm. Custom sizes are also available upon request.

Packaging: The plates are carefully packaged in sturdy wooden boxes to ensure safe delivery and handling during transportation.

Our Hastelloy C276 plates come with comprehensive technical support and after-sales services to ensure smooth and reliable use. We provide:

Consultation & Specifications: Expert support to help determine the best material for your application.

Fabrication Assistance: Guidance on welding, machining, and forming the plates to suit specific project needs.

Maintenance Guidance: Recommendations for care, handling, and maintenance to extend the lifespan of the product.

Replacement & Repair Services: Prompt assistance in case of any product defects or issues during use.

Product: Hastelloy C276 Plate

Dimensions: 12 inches x 12 inches x 1/4 inch (custom sizes available)

Weight: 5 pounds (varies with size)

Packaging: Sturdy cardboard box with bubble wrap and cushioning materials for safe transportation.

Shipping: Free standard shipping within the continental U.S. via UPS Ground. Expedited shipping options available for an additional fee.

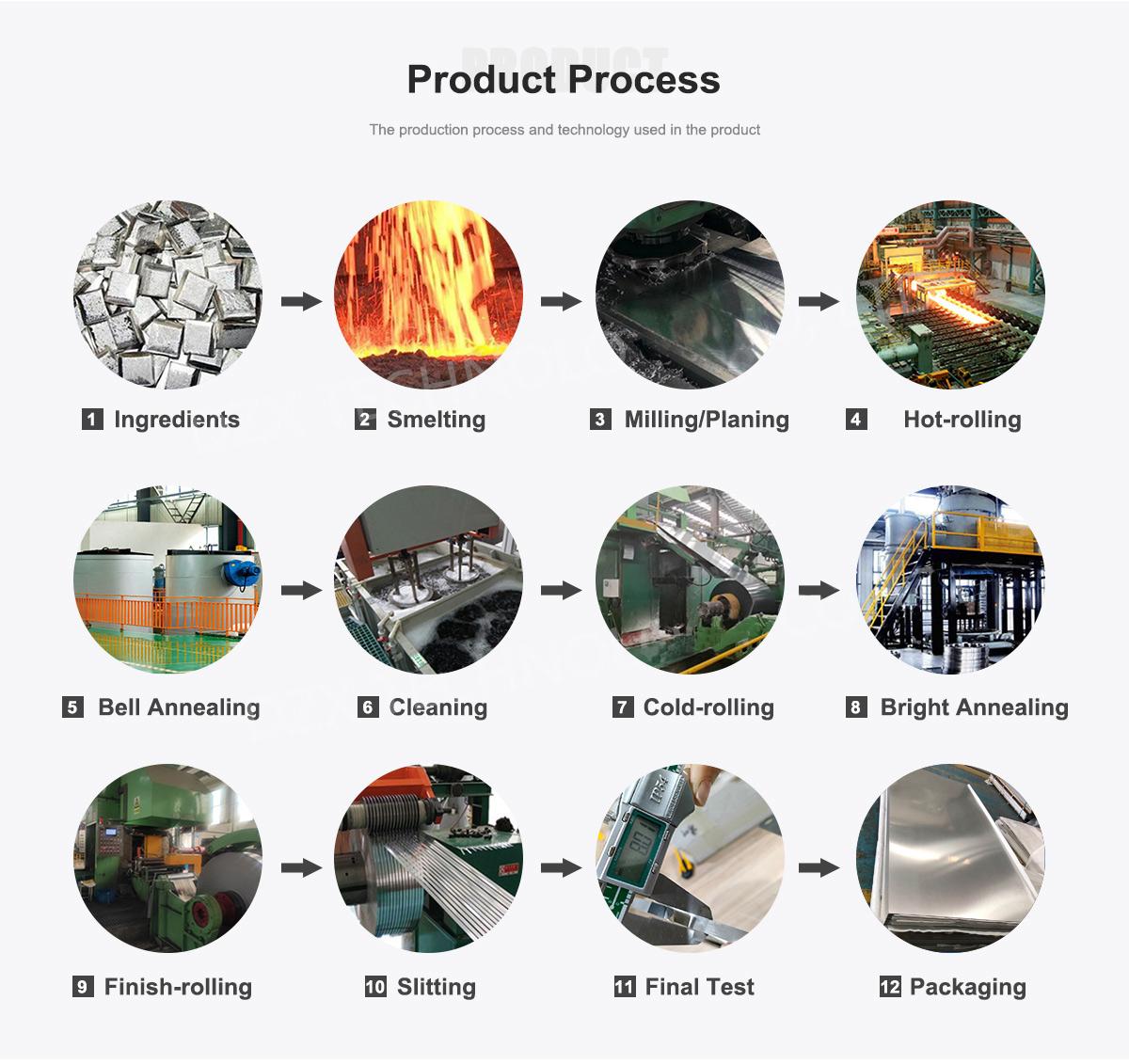

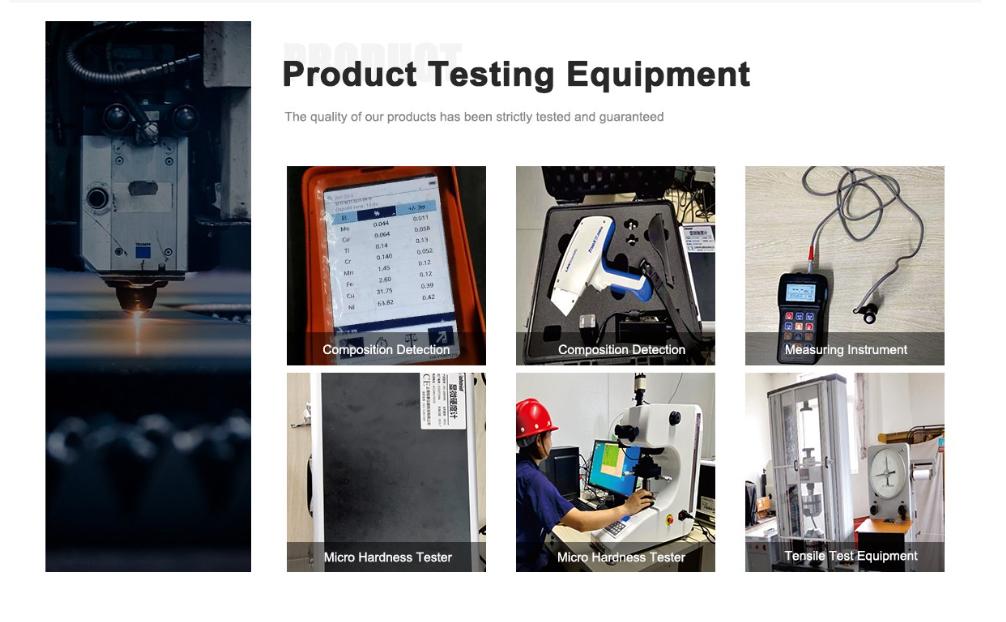

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got ISO9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, Precision Alloy , FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

1. What is the material composition of Hastelloy C276?

Hastelloy C276 is primarily composed of nickel, molybdenum, chromium, and tungsten. These elements give it exceptional resistance to both oxidizing and reducing environments, as well as superior resistance to pitting and stress corrosion cracking.

2. What are the available dimensions of Hastelloy C276 plates?

Hastelloy C276 plates come in standard sizes of 1000mm x 2000mm, 1219mm x 2438mm, and 1500mm x 6000mm. Custom sizes are also available upon request.

3. What industries can use Hastelloy C276 plate?

Hastelloy C276 plates are used in industries such as chemical processing, aerospace, marine, pollution control, oil & gas, and power generation, where high-temperature and corrosion resistance are critical.

4. How should I store Hastelloy C276 plates?

Hastelloy C276 plates should be stored in a dry, clean environment away from extreme temperatures and moisture to prevent contamination.

5. What is the maximum temperature resistance of Hastelloy C276?

Hastelloy C276 can withstand temperatures up to 1,900°F (1,038°C), making it suitable for high-temperature applications in various industries.