Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

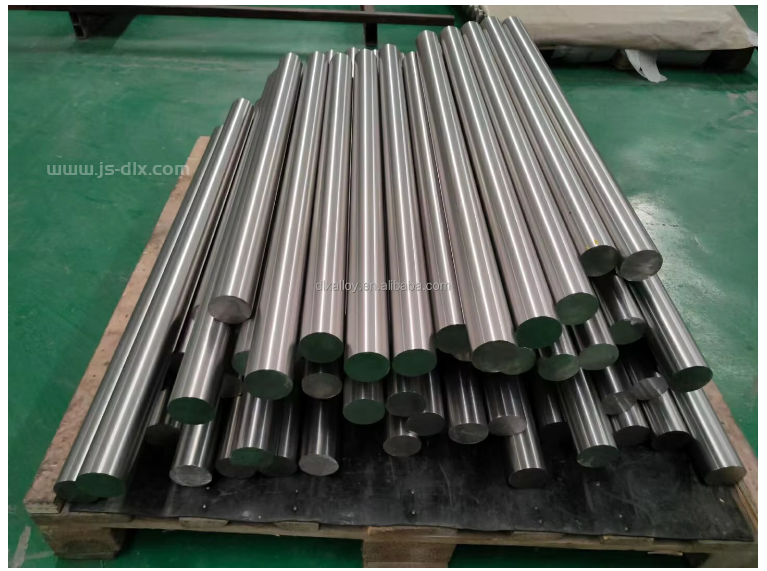

Inconel bar & Rod

Product Details

Inconel X750 is a nickel-chromium-iron alloy that is known for its exceptional high-temperature strength and oxidation resistance. It is designed to withstand extreme conditions,

making it suitable for various demanding applications, particularly in the aerospace and power generation industries.

High-Temperature Strength: Retains mechanical properties at temperatures up to approximately 700°C (1292°F).

Oxidation and Corrosion Resistance: Excellent resistance to oxidation and corrosion in aggressive environments.

Fabricability: Can be easily formed, welded, and machined using conventional techniques.

Versatility: Ideal for applications such as gas turbines, heat exchangers, and combustion components.

UNS | W.Nr |

N07750 | 2.4669 |

Grade | % | Ni | Cr | Fe | Nb | Co | C | Mn | Si | S | Cu | Al | Ti | P |

X-750 | Min | Bal. | 14 | 5.0 | 0.7 | 0.4 | 2.25 | |||||||

Max | 17 | 9.0 | 1.2 | 1.00 | 0.08 | 1.00 | 0.50 | 0.01 | 0.5 | 1.0 | 2.75 | 0.02 |

σb/MPa | Yield Strength σp0.2/MPa | Elongation σ5 /% |

910 | 550 | 25 |

Standard

Bar | Forging | Sheet/Strip | Wire |

ASTM B637

| ASTM B637 | AMS 5542 | AMS 5698 |

Aerospace: Used in gas turbine components, such as blades and seals, due to its ability to withstand high temperatures and stress.

Nuclear Industry: Employed in reactor cores and other components where resistance to radiation and high temperatures is critical.

Oil and Gas: Utilized in downhole tubing and valves, where corrosion resistance is essential.

Chemical Processing: Suitable for heat exchangers, reactors, and other equipment exposed to harsh chemicals.

Industrial Furnaces: Used in components that require high-temperature strength and resistance to oxidation.

Producing an Inconel X750 bar involves several key steps, including material selection, melting, forming, and finishing. Here's an overview of the process:

1. Material Selection

Raw Materials: Gather the necessary alloying elements, primarily nickel, chromium, iron, and small amounts of other elements like titanium and aluminum.

2. Melting

Induction or Electric Arc Furnace: The raw materials are melted in a controlled environment using either an induction furnace or an electric arc furnace to ensure homogeneity.

Alloy Composition: Monitor and adjust the composition as needed to meet the specifications for Inconel X750.

3. Casting

Ingot Casting: Pour the molten alloy into molds to form ingots. This can be done via sand casting or investment casting techniques.

Cooling: Allow the ingots to cool slowly to prevent cracking and ensure uniformity.

4. Forging

Hot Forging: The cooled ingots are heated and then forged into bars. This process improves mechanical properties by refining the grain structure.

Shaping: The bars are shaped to the desired dimensions through various forging techniques.

5. Heat Treatment

Solution Annealing: The forged bars are heated to a specific temperature, then rapidly cooled to dissolve any precipitates.

Aging: The bars are then aged at a lower temperature to enhance strength and stability, typically around 1300°F (700°C) for several hours.

6. Machining

Cutting and Shaping: The bars may be machined to precise dimensions using conventional machining techniques, such as turning, milling, and grinding.

Surface Finishing: Apply surface treatments as necessary to achieve the desired finish and surface quality.

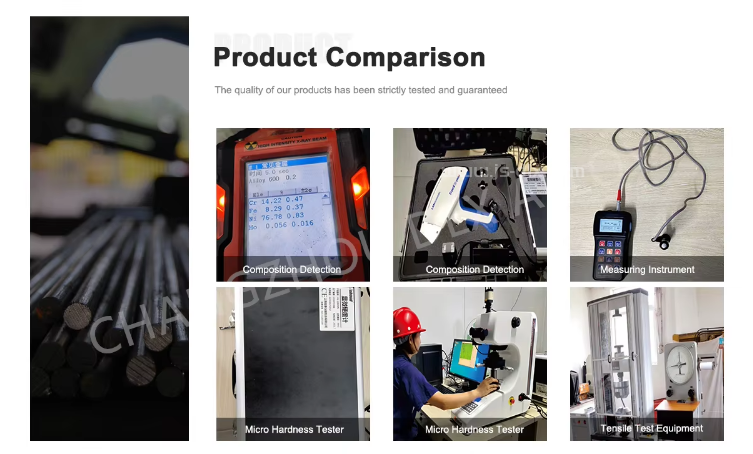

7. Inspection and Testing

Quality Control: Conduct non-destructive testing (NDT) and mechanical testing to ensure the bars meet the required specifications for strength, ductility, and corrosion resistance.

Documentation: Maintain records of the production process, material properties, and inspection results.

8. Packaging and Shipping

Final Inspection: Perform a final inspection before packaging.

Shipping: Package the bars for shipment to customers or further processing.

What is your working time?

Monday-Saturday : 7:30AM-17:00PM (Beijing time, GMT+08.00) We have public holiday during May.1-3, Oct.1-7 and Chinese New Year holiday . Pls email us during our holiday if u have any question.

mobile/whatsapp/skype/wechat:+8618961410953, Joyce

Do you provide free samples?

Yes, we can provide a free sample for testing,buyer should bear all the shipping costs.

What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

What is the lead time?

Usually sample lead time is 7 days after payment has been confirmed.