Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Inconel Pipe

Product Details

Product Description

Inconel 625 coils are renowned for their exceptional resistance to corrosion, making them highly effective in challenging environments with exposure to corrosive chemicals. This nickel alloy maintains its strength under high temperatures and demonstrates impressive durability, which is why it's favored in aerospace and power generation sectors. Its ability to withstand extreme conditions ensures the reliable and safe operation of critical components.

Differences between nickel-based welded pipes and coils

1. Form Factor

- Welded Pipes: Generally straight and cylindrical, specifically engineered for fluid or gas transport.

- Coils: Characterized by their curved or coiled shape, often employed in heat exchange or scenarios requiring flexibility.

2. Manufacturing Process

- Welded Pipes:Created by fusing flat sheets of nickel-based alloys into a tubular form.

- Coils: Formed by bending nickel-based materials into coils, facilitating installation in confined areas.

3. Applications

- Welded Pipes:Frequently utilized in oil and gas sectors, chemical processing, and construction for fluid transportation.

- Coils:Commonly found in heat exchangers, refrigeration units, and other applications demanding flexibility.

4. Mechanical Properties

- Welded Pipes: Typically possess high strength and rigidity, making them suitable for high-pressure conditions.

- Coils: Often offer greater flexibility and reduced weight, simplifying handling in specific installations.

5. Heat Resistance

- Welded Pipes:Built to endure extreme temperatures and pressures, ensuring reliability in challenging environments.

- Coils:Although also heat-resistant, they are primarily designed for efficient heat transfer applications.

6. Corrosion Resistance

- Welded Pipes: Provide outstanding resistance to corrosion, particularly in harsh conditions, due to the characteristics of nickel alloys.

- Coils:Also exhibit good corrosion resistance, though their performance may vary based on design and intended use.

7. Installation Requirements

- Welded Pipes: Typically necessitate sturdy support and precise alignment during installation.

- Coils: More adaptable for installation, as they can be easily shaped to fit into tighter spaces.

8. Cost Factors

- Welded Pipes:May incur higher costs owing to their manufacturing processes and material types.

- Coils:Pricing can fluctuate based on the specific application and length required, potentially making them more economical in flexible settings.

These points underscore the key distinctions between welded pipes and coils in various aspects.

Feel free to ask for further adjustments!

Detailed Information

In order to evaluate the strength and durability of Inconel 625 coils, we conduct water pressure tests. This procedure involves filling the coils with water and gradually increasing the pressure to assess their ability to withstand extreme conditions. The testing process includes several key steps:

Preparation and Inspection: Coils are thoroughly checked and cleaned to remove any contaminants.

Sealing Mechanism: Both ends of the coils are securely sealed to prevent water from escaping.

Filling Process: The coils are filled with water, ensuring that all air is expelled for accurate pressure readings.

Pressure Application: Pressure is incrementally increased to the specified testing level, often exceeding normal operating conditions to assess integrity.

Monitoring: Throughout the test, pressure is closely monitored, and any signs of leakage or deformation are documented.

Final Evaluation: After testing, the coils are inspected for any damage or weaknesses to ensure compliance with safety standards.

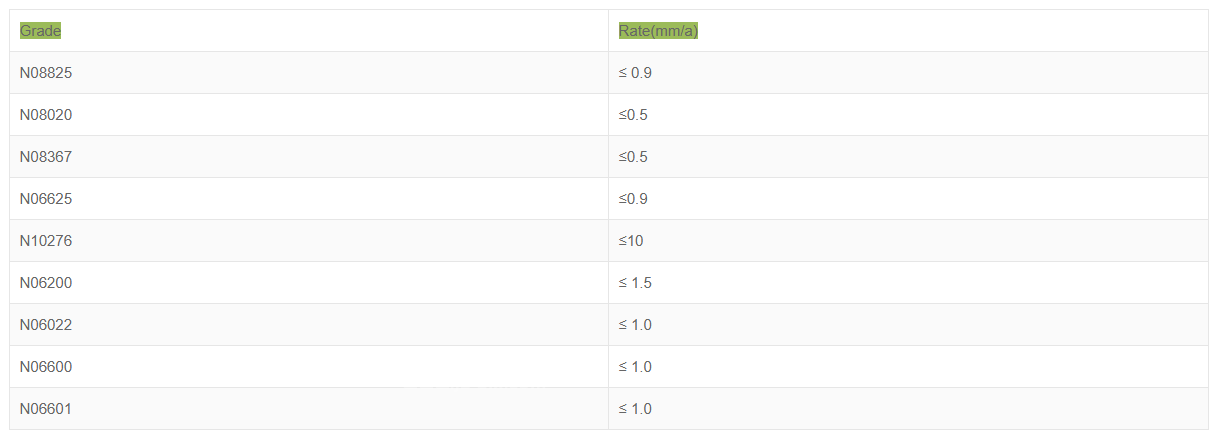

Corrosion Resistance Of Different Materials(G28 A Methord)

DLX ALLOY has advanced equipment, proven techniques, and professional teams. We strictly implement the Quality Management System and API Requirements to ensure that the quality meets the needs of the site. The tests like, NDT | X-ray | Tension test | Hydrostatic test

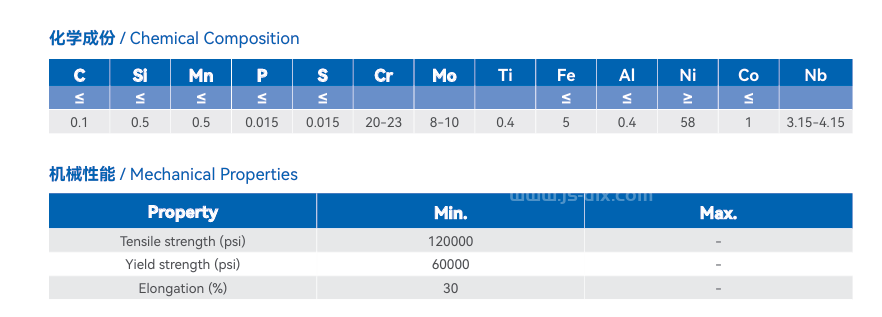

Product Parameters

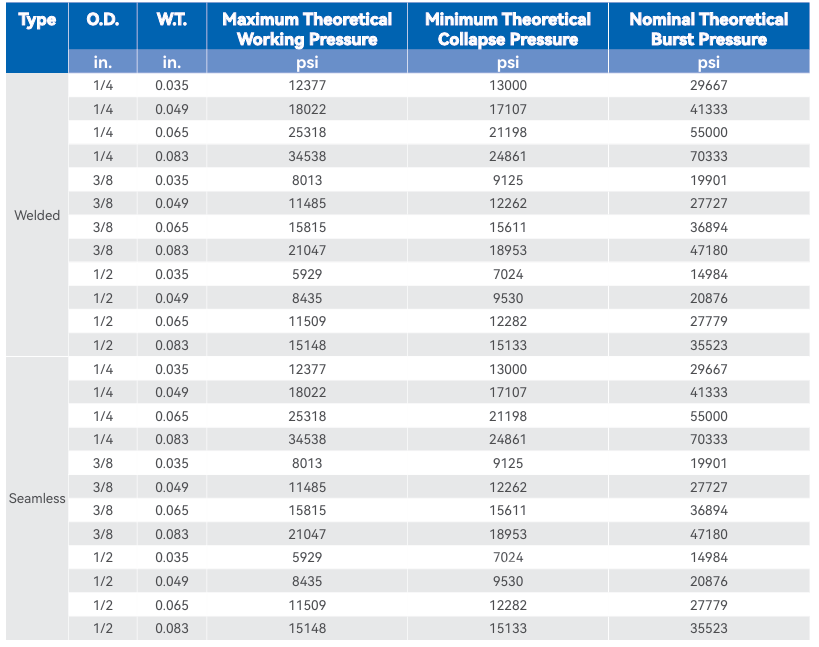

Size Dependant Characteristics (Based Upon Nominal Tubing Dimensions)

Recommended products

Company Profile

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

If any requirements and questions, please feel free to reach:

Sophie Wang | Sales +86 19906119641

International Sales Depart.

Jiangsu Victory Technology Co., Ltd

A: NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu

FAQ