Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Inconel Pipe

Product Details

Inconel Alloys, including Inconel 625, 600, 718, X750, and 800, are high-performance nickel-based alloys known for their exceptional resistance to heat, oxidation, and corrosion. These alloys are specifically designed for high-temperature applications and are widely used in industries where performance under extreme conditions is essential.

Inconel alloys are known for their ability to withstand elevated temperatures, ranging from 600°C to over 1000°C (1112°F to 1832°F), while maintaining high strength and resistance to oxidation and corrosion. The exceptional mechanical properties of these alloys make them the ideal choice for various heat-resistant applications in industries like aerospace, chemical processing, power generation, and oil & gas.

Our Inconel Pipe s are available in various forms such as tubes, bars, plates, and sheets, offering flexibility in use for a wide array of applications. With exceptional mechanical strength, high yield strength, and resistance to high-temperature oxidation, Inconel alloys are engineered to deliver consistent performance even in the most demanding environments.

Item | Inconel 600 | Inconel 625 | Inconel 718 | Inconel X750 | Inconel 825 | |||

C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

Fe | 6-10 | rest | ≤3 | rest | 7-11 | rest | 5-9 | ≥22 |

P | ≤0.015 | ≤0.02 | ≤0.015 | -- | -- | -- | -- | -- |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

Cu | ≤0.5 | ≤1 | -- | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

Ni | ≥72 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

Co | -- | -- | 10-15 | ≤10 | -- | ≤1 | ≤1 | -- |

Al | -- | 1-1.7 | 0.8-1.5 | ≤0.8 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

Ti | -- | -- | ≤0.6 | ≤1.15 | -- | -- | 2.25-2.75 | 0.6-1.2 |

Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

Nb+Ta | -- | -- | -- | 4.75-5.5 | -- | 4.75-5.5 | 0.7-1.2 | -- |

Mo | -- | -- | 8-10 | 2.8-3.3 | -- | 2.8-3.3 | -- | 2.5-3.5 |

B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

Shape | Size (mm) |

Wire | 0.02-7.50 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Customized |

Sheet/Plate | Customized |

Key Features:

High-Temperature Resistance: These Inconel alloys can withstand extreme temperatures without significant loss of strength, making them suitable for high-temperature environments.

Corrosion Resistance: The alloys exhibit excellent resistance to both oxidation and carburization at high temperatures, ensuring their durability in corrosive environments.

Mechanical Strength: Inconel alloys possess excellent mechanical properties, including high tensile strength and yield strength, making them ideal for applications under stress.

Versatility: Available in a variety of grades and forms, such as Inconel 625, 600, 718, X750, and 800, which cater to specific applications in industries like aerospace, chemical processing, and energy generation.

Weldability: These alloys can be welded with standard welding techniques, which makes them easy to integrate into complex systems.

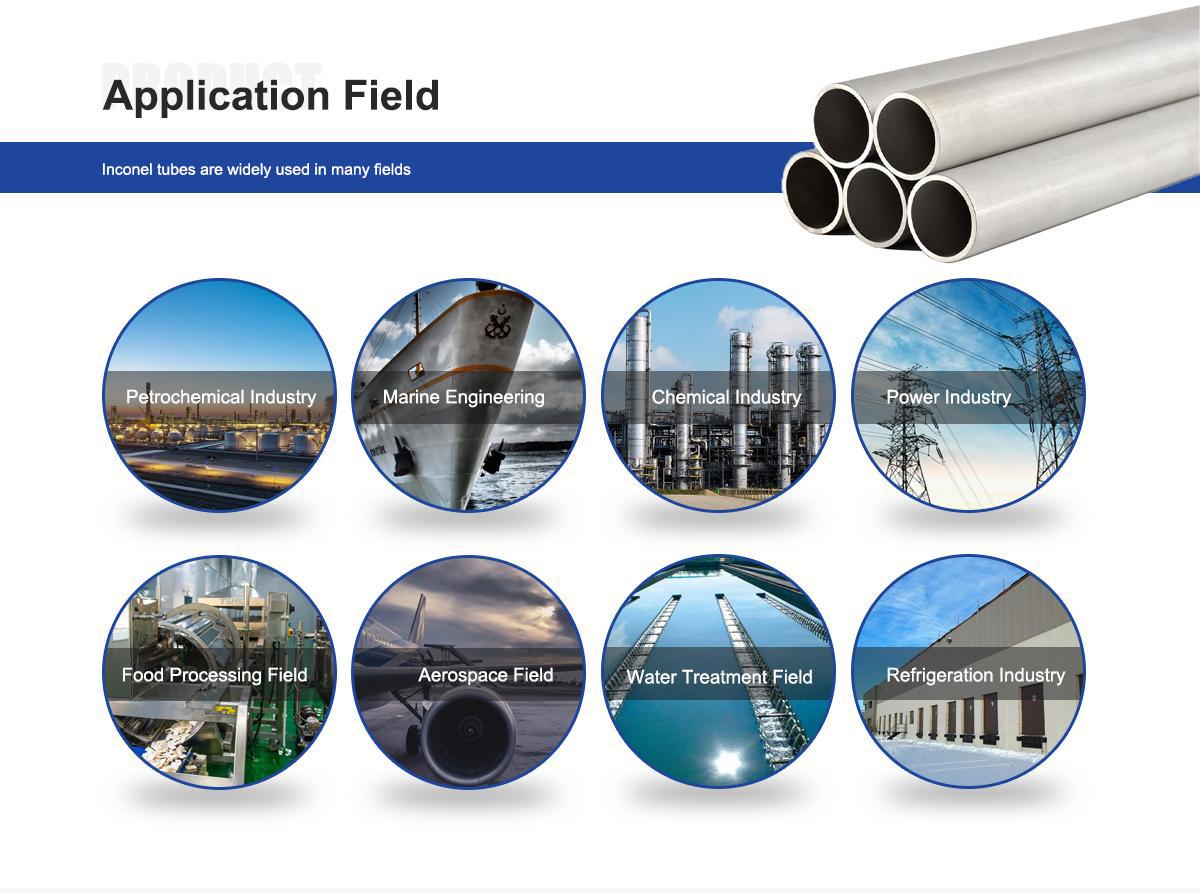

Applications:

Aerospace Industry:

Inconel alloys, especially Inconel 625 and 718, are widely used in jet engines, gas turbines, exhaust systems, and burner components due to their high-temperature stability and resistance to thermal fatigue.

Chemical Processing:

Inconel alloys are ideal for applications involving chemical reactors, heat exchangers, distillation columns, and other equipment that require resistance to corrosion, high temperatures, and stress.

Oil & Gas Industry:

These alloys are used for manufacturing valves, pumps, pipelines, and pressure vessels, especially in offshore and subsea applications where they are exposed to harsh conditions like seawater corrosion and high temperatures.

Power Generation:

Inconel alloys are commonly used in gas turbines, steam turbines, and boilers, where they help withstand high-temperature and high-pressure environments, thus improving the reliability and performance of energy systems.

Nuclear Power Plants:

Inconel 600 and 800 are used in nuclear reactors due to their excellent resistance to radiation and high temperature, ensuring they remain functional over long periods.

Heat-Resistant Components:

Inconel alloys are widely used in manufacturing heat-resistant components like furnace parts, combustion chambers, burner nozzles, and heat exchangers, which require exceptional durability under thermal and mechanical stress.

Product Customization Options:

Grades Available: Inconel 625, 600, 718, X750, and 800

Forms Available: Tubes, bars, sheets, and plates

Surface Finishes: Polished, matte, or custom finishes

Thicknesses and Sizes: Customized to fit your specific needs

Welding Services: We offer welding and machining services to meet your application requirements.

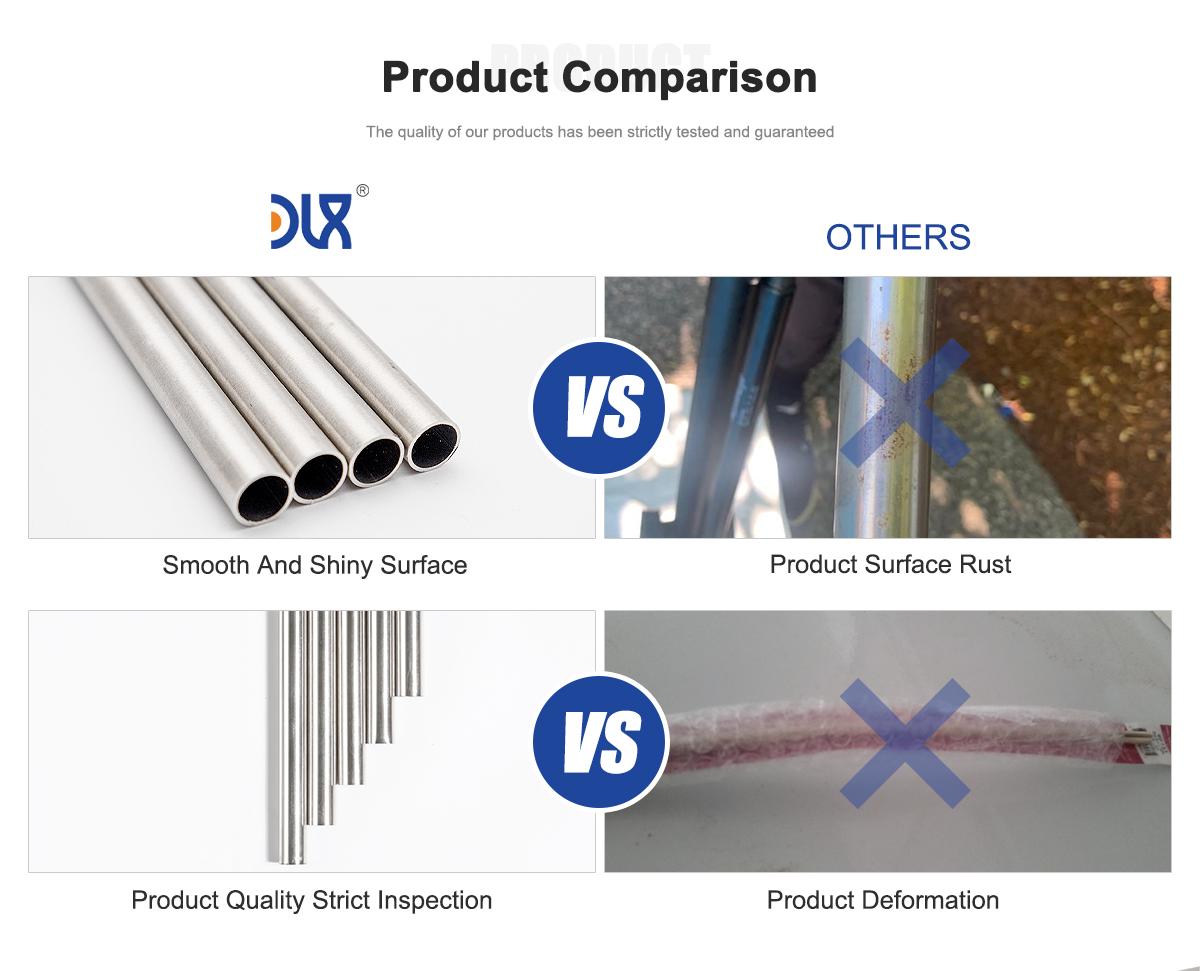

Product Advantages:

High-Temperature Strength: These alloys maintain their strength even at elevated temperatures, ensuring long-term performance in extreme conditions.

Corrosion & Oxidation Resistance: Excellent resistance to oxidation and corrosion in environments with high temperatures and corrosive substances.

Fatigue and Thermal Fatigue Resistance: The alloys resist fatigue and thermal cycling, ensuring durability even in fluctuating temperature conditions.

Long Service Life: The durability and high resistance to thermal and mechanical stress ensure that components made from Inconel alloys offer a long service life, minimizing maintenance needs.

Packing and Shipping:

Packaging: Inconel pipes and alloys are carefully packed in wooden crates or sturdy cartons to prevent damage during shipping. They are also wrapped in protective layers to prevent scratches or corrosion during transport.

Shipping: We offer reliable and global shipping options, including standard and expedited delivery. Shipping is done through trusted carriers like UPS, FedEx, or DHL. Delivery times vary depending on location.

FAQ:

Q1: What are the main differences between Inconel 625, 600, 718, X750, and 800?

A1:

Inconel 625: Offers excellent oxidation and corrosion resistance, ideal for extreme environments like aerospace and chemical processing.

Inconel 600: Known for its high-temperature strength and oxidation resistance, commonly used in nuclear applications and chemical processing.

Inconel 718: A high-strength, corrosion-resistant alloy widely used in aerospace for turbine blades and structural components.

Inconel X750: Primarily used for gas turbines due to its high creep-rupture strength at high temperatures.

Inconel 800: Suitable for high-temperature applications in the power generation industry due to its strength and resistance to oxidation.

Q2: How do I choose the right Inconel alloy for my application?

A2: Choosing the right alloy depends on the operating conditions. For extreme temperatures and oxidation resistance, Inconel 625 is ideal. For high-strength applications in aerospace or gas turbines, Inconel 718 or X750 would be better suited. For general high-temperature use, Inconel 600 and 800 offer excellent performance.

Q3: Can I customize the thickness of the Inconel pipes?

A3: Yes, we offer customized thickness options. Please provide your requirements, and we can produce the pipe to your exact specifications.

Q4: Is Inconel easy to weld?

A4: Yes, Inconel alloys can be welded using conventional welding techniques, making them highly versatile for use in various applications.

Q5: What industries benefit from using Inconel alloys?

A5: Inconel alloys are used in industries such as aerospace, chemical processing, oil & gas, power generation, and nuclear power, due to their high-temperature strength and excellent resistance to oxidation and corrosion.