Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Inconel Strip

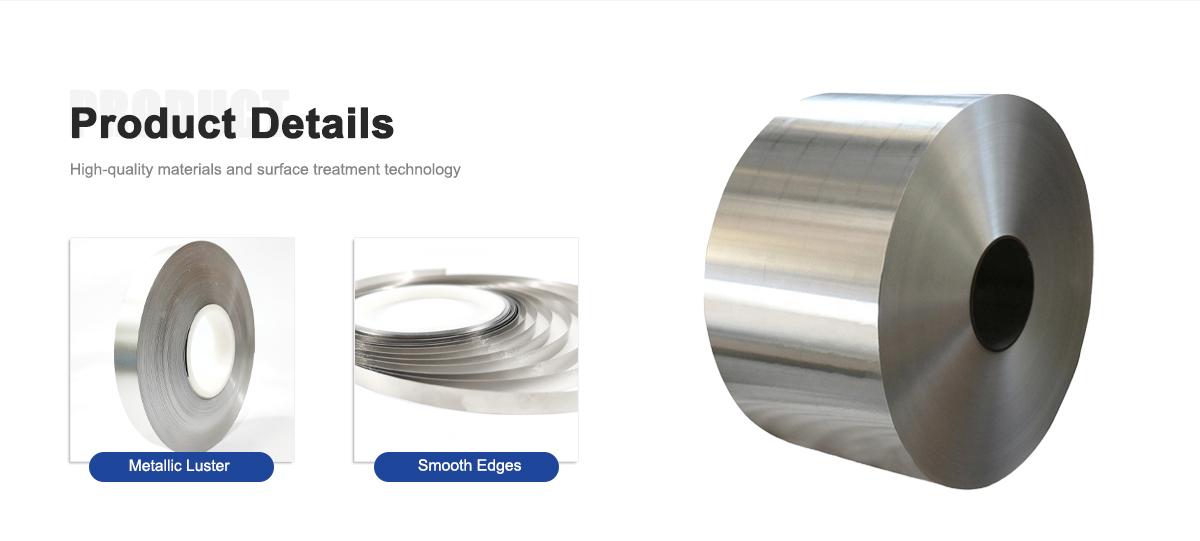

Product Details

Inconel 718 strips are a critical material in aerospace manufacturing, known for their exceptional strength, high-temperature stability, and corrosion resistance. These strips play an essential role in high-performance applications, particularly within gas turbines, where reliability under extreme conditions is paramount. Thanks to their unique properties, Inconel 718 strips enhance the efficiency of energy conversion systems, making them indispensable in modern aerospace and energy production.

Item | Inconel 625 | Inconel 718 | Inconel 825 | |||||

C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

Fe | 6-10 | rest | ≤3 | rest | 7-11 | rest | 5-9 | ≥22 |

P | ≤0.015 | ≤0.02 | ≤0.015 | -- | -- | -- | -- | -- |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

Cu | ≤0.5 | ≤1 | -- | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

Ni | ≥72 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

Co | -- | -- | 10-15 | ≤10 | -- | ≤1 | ≤1 | -- |

Al | -- | 1-1.7 | 0.8-1.5 | ≤0.8 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

Ti | -- | -- | ≤0.6 | ≤1.15 | -- | -- | 2.25-2.75 | 0.6-1.2 |

Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

Nb+Ta | -- | -- | -- | 4.75-5.5 | -- | 4.75-5.5 | 0.7-1.2 | -- |

Mo | -- | -- | 8-10 | 2.8-3.3 | -- | 2.8-3.3 | -- | 2.5-3.5 |

B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

Shape | Size (mm) |

Wire | 0.02-7.50 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Customized |

Sheet/Plate | Customized |

High-Temperature Performance: Inconel 718 strips can withstand extreme heat, making them ideal for aerospace applications, such as turbine blades and combustion chambers.

Corrosion Resistance: These strips offer exceptional protection against oxidation and corrosion, ensuring a long service life in harsh environments, including those found in chemical processing and aerospace systems.

Mechanical Strength: With high tensile strength, Inconel 718 strips can endure significant stress and pressure, making them perfect for the oil, gas, and aerospace industries.

Custom Fabrication: Inconel 718 can be fabricated into a wide variety of shapes, accommodating diverse aerospace and industrial applications, from engine components to structural parts.

Weldability: These strips are easily welded using standard techniques, ensuring seamless integration into complex aerospace and engineering projects.

Thermal Stability: Inconel 718 strips maintain structural integrity under fluctuating temperatures, ensuring they perform well in gas turbines, heat exchangers, and other high-heat environments.

Extended Durability: Their combination of corrosion resistance and mechanical strength ensures a long service life, reducing the need for frequent maintenance or replacements.

Cracking Resistance: Designed to resist stress corrosion cracking, Inconel 718 strips are highly reliable in aerospace and oil & gas applications, where environmental conditions are often extreme.

Chemical Compatibility: Inconel 718 strips are resistant to a wide range of chemicals, making them ideal for use in chemical processing and other aggressive environments.

Inconel 718 strips are widely used in a variety of high-performance industries, particularly aerospace manufacturing. Their unique properties make them a go-to material for critical applications that demand both strength and reliability.

Aerospace Industry: Inconel 718 is used extensively in turbine blades, combustion chambers, and other components of jet engines and rockets. Its ability to perform under extreme temperatures and pressures makes it indispensable in the aerospace sector.

Gas Turbine Manufacturing: The high thermal stability and mechanical strength of Inconel 718 strips make them ideal for components in gas turbines, which operate under harsh conditions.

Oil & Gas Sector: Inconel 718 strips are commonly used in valves, heat exchangers, and piping systems within the oil and gas industry, where they must withstand high pressure and exposure to aggressive chemicals.

Power Generation: Inconel 718 strips are vital in power generation equipment such as turbines and reactors, where their high resistance to corrosion and thermal stability help optimize energy conversion processes.

Chemical Processing: Inconel 718 is frequently used in chemical reactors, heat exchangers, and other systems that handle highly corrosive substances at elevated temperatures.

The manufacturing of Inconel 718 strips involves a meticulous process to ensure optimal performance. The alloy is carefully melted, cast, and rolled to achieve the desired dimensions. Afterward, the strips undergo heat treatment to enhance their mechanical properties, such as tensile strength and resistance to fatigue. This ensures the strips maintain their integrity even under extreme thermal conditions, making them suitable for aerospace and other high-performance industries.

The fabrication of Inconel 718 can be customized according to specific application requirements. The material can be shaped into various configurations, ensuring versatility in different sectors like aerospace, automotive, and power generation.

Durability Under Extreme Conditions: Inconel 718 strips are designed to thrive in environments with extreme heat, high pressure, and corrosive substances. This makes them an excellent choice for aerospace, oil & gas, and power generation industries, where reliability is critical.

Customizable and Flexible: These strips can be fabricated into different shapes and sizes to meet the unique requirements of various applications. Their weldability also ensures they can be integrated into complex systems with ease.

Cost-Efficient Long-Term: While the initial cost of Inconel 718 strips may be higher than alternative materials, their long service life and reduced maintenance requirements make them a cost-effective choice over time.

High-Performance in Harsh Environments: Inconel 718 strips perform reliably in extreme conditions, from aerospace engines to chemical reactors, ensuring consistent and optimal performance across different industries.

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got ISO9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, Precision Alloy , FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

1. What are your working hours and how can I contact you?

Our working hours are Monday to Saturday from 7:30 AM to 5:00 PM (Beijing time, GMT+08.00). We observe public holidays during May 1-3, October 1-7, and Chinese New Year. Please feel free to email us during these holidays if you have any inquiries.

2. Do you offer free samples?

Yes, we provide free samples for testing. However, the buyer is responsible for the shipping costs.

3. What are your payment terms?

We accept the following payment methods: T/T, L/C, D/A, D/P, Western Union, MoneyGram, and PayPal.

4. What is the lead time for orders?

Typically, the sample lead time is 7 days after payment confirmation. For bulk orders, the lead time will depend on the quantity and specifications.

5. How can I place an order for Inconel 718 strips?

To place an order, simply contact our sales team via email or phone. Our team will guide you through the selection process and provide a detailed quote based on your specific needs.