Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Inconel Wire

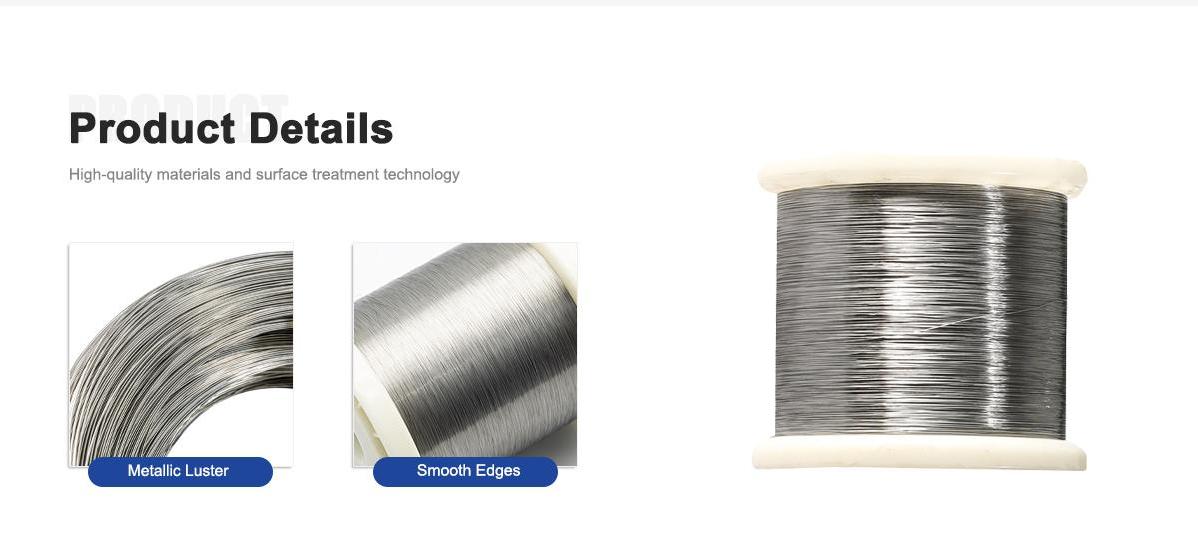

Product Details

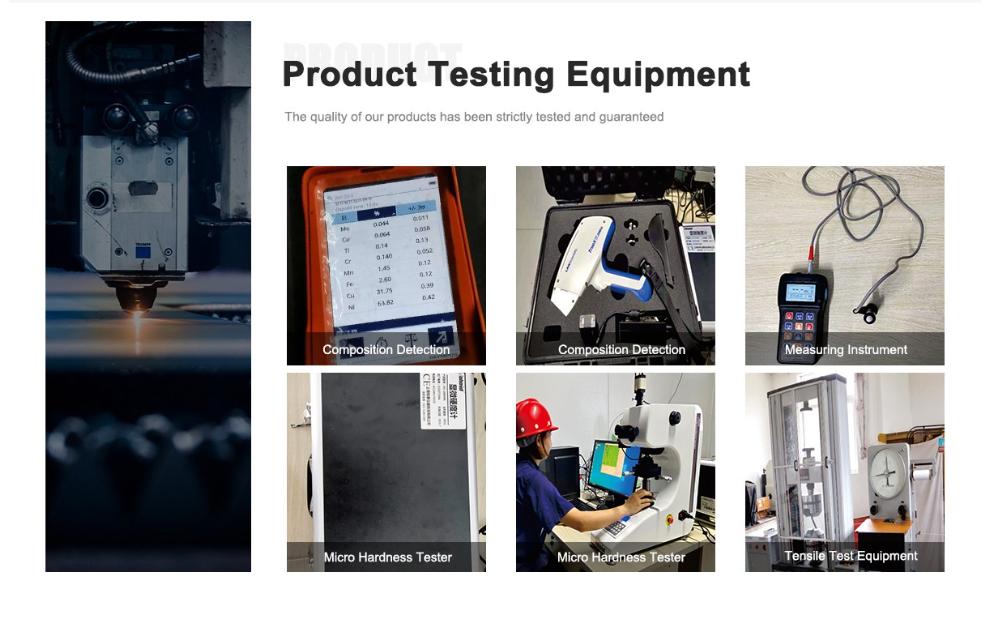

Inconel 617 wire is a high-performance alloy wire designed for thermal stability and corrosion resistance in extreme environments. This wire excels in industries that demand materials capable of withstanding high temperatures and aggressive chemicals. Its superior properties make it essential for critical applications such as chemical tanks, heat exchangers, and turbine components. Inconel 617 wire is especially valued for its strength, durability, and reliability in high-performance, high-temperature, and corrosive environments.

Item | Inconel 600 | Inconel 625 | Inconel X750 | Inconel 825 | ||||

C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

Fe | 6-10 | rest | ≤3 | rest | 7-11 | rest | 5-9 | ≥22 |

P | ≤0.015 | ≤0.02 | ≤0.015 | -- | -- | -- | -- | -- |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

Cu | ≤0.5 | ≤1 | -- | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

Ni | ≥72 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

Co | -- | -- | 10-15 | ≤10 | -- | ≤1 | ≤1 | -- |

Al | -- | 1-1.7 | 0.8-1.5 | ≤0.8 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

Ti | -- | -- | ≤0.6 | ≤1.15 | -- | -- | 2.25-2.75 | 0.6-1.2 |

Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

Nb+Ta | -- | -- | -- | 4.75-5.5 | -- | 4.75-5.5 | 0.7-1.2 | -- |

Mo | -- | -- | 8-10 | 2.8-3.3 | -- | 2.8-3.3 | -- | 2.5-3.5 |

B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

Shape | Size (mm) |

Wire | 0.02-7.50 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Customized |

Sheet/Plate | Customized |

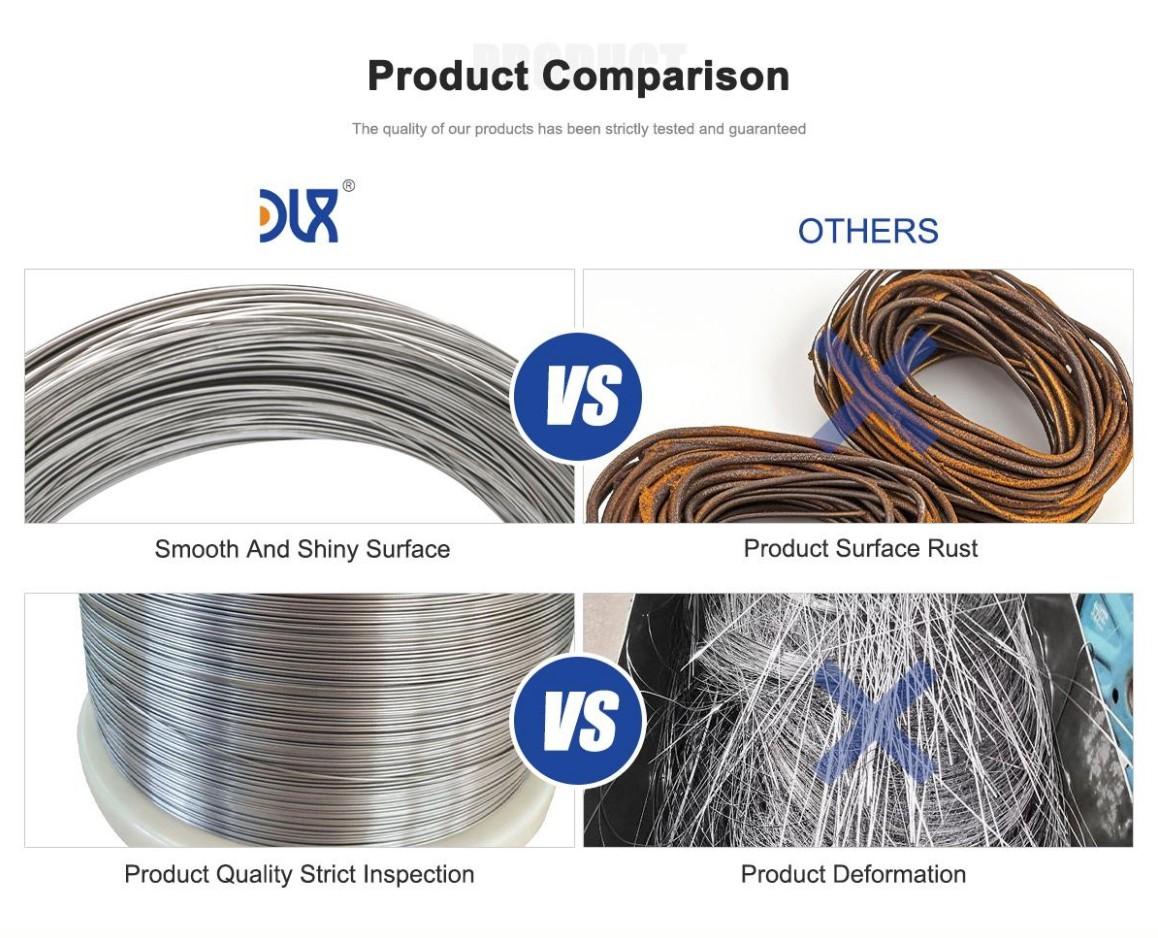

Exceptional Corrosion Resistance: Inconel 617 wire is engineered to withstand a broad range of aggressive chemicals, including acids, chlorides, and seawater, making it perfect for chemical tanks and other environments where corrosion resistance is crucial.

High-Temperature Stability: This wire can endure extreme heat conditions up to 1150°C (2102°F) without losing its structural integrity, making it ideal for applications where materials need to resist oxidation and degradation at high temperatures.

Robust Mechanical Strength: The wire has impressive tensile strength and yield strength, enabling it to perform under high stress and maintain its form even in demanding industrial environments.

Versatile Fabrication: Inconel 617 wire can be easily shaped into various forms, offering flexibility for a wide range of applications, from complex systems to standard industrial uses.

Ease of Integration: The wire is compatible with common welding techniques, making it easy to integrate into existing systems without requiring specialized equipment.

Inconel 617 wire’s high resistance to corrosion and thermal stability makes it indispensable in a variety of industries. Some common applications include:

Chemical Processing: The wire’s ability to resist a wide range of chemicals and its high-temperature endurance makes it ideal for heat exchangers and reactors in the chemical industry.

Aerospace Engineering: Inconel 617 wire is vital for the manufacturing of turbine blades and exhaust systems in the aerospace industry, where high temperatures and mechanical stress are commonplace.

Oil and Gas: In the oil and gas industry, Inconel 617 wire is used in downhole tubing, pipelines, and offshore rigs, where its superior corrosion resistance ensures long-term performance under extreme pressure and exposure to harsh environments.

Nuclear Power: In nuclear reactors, the wire is used for components that require resistance to both radiation damage and high temperatures, ensuring continued safe operation of the reactor.

Marine Engineering: The wire is used in valves, propeller shafts, and other critical marine components to withstand corrosion in seawater environments.

Energy Production: In energy generation systems, Inconel 617 wire plays a key role in enhancing energy conversion efficiency in high-temperature applications.

Heating Systems: The wire’s high thermal resistance makes it a perfect material for industrial furnace heating elements, ensuring long-lasting performance at elevated temperatures.

Pharmaceutical Manufacturing: In the pharmaceutical industry, where corrosion resistance and material purity are critical, Inconel 617 wire is used in equipment exposed to harsh chemical environments.

Unmatched Corrosion Resistance: With high levels of nickel and chromium, Inconel 617 wire offers outstanding resistance to a variety of corrosive environments, including acids, chlorides, and seawater, making it ideal for chemical tanks.

High-Temperature Stability: Capable of withstanding temperatures up to 1150°C (2102°F), this wire provides excellent performance in applications that involve extreme thermal conditions.

Mechanical Strength: The wire’s high tensile and yield strengths ensure that it can withstand significant mechanical stress without deforming or failing.

Flexibility in Fabrication: Inconel 617 wire can be shaped into a variety of forms, making it adaptable to different industrial needs and ensuring its application across various sectors.

Ease of Integration: This wire is compatible with standard welding techniques, facilitating straightforward installation and integration into existing systems.

What is Inconel 617 wire used for?

Inconel 617 wire is primarily used for thermal spray coatings, chemical tanks, and components in high-temperature and corrosive environments, including gas turbines, heat exchangers, and nuclear reactors.

What industries use Inconel 617 wire?

Inconel 617 wire is widely used in industries such as chemical processing, aerospace, oil and gas, nuclear power, marine engineering, and energy production.

What are the key benefits of Inconel 617 wire?

Inconel 617 wire provides exceptional corrosion resistance, high-temperature stability, and mechanical strength, making it ideal for use in harsh environments and demanding applications.

How does Inconel 617 wire perform in corrosive environments?

Inconel 617 wire is designed to resist acids, chlorides, seawater, and other aggressive chemicals, ensuring longevity in chemical tanks and other environments exposed to harsh substances.

What is the maximum temperature that Inconel 617 wire can withstand?

Inconel 617 wire can withstand temperatures up to 1150°C (2102°F), ensuring stable performance even in high-heat conditions.

Can Inconel 617 wire be welded?

Yes, Inconel 617 wire is compatible with standard welding techniques, which allows for easy integration into various industrial systems.

How can I order Inconel 617 wire?

To place an order or inquire about pricing, please contact Sophie Wang, Sales at +86 19906119641, or email us directly for more information.