Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Inconel Wire

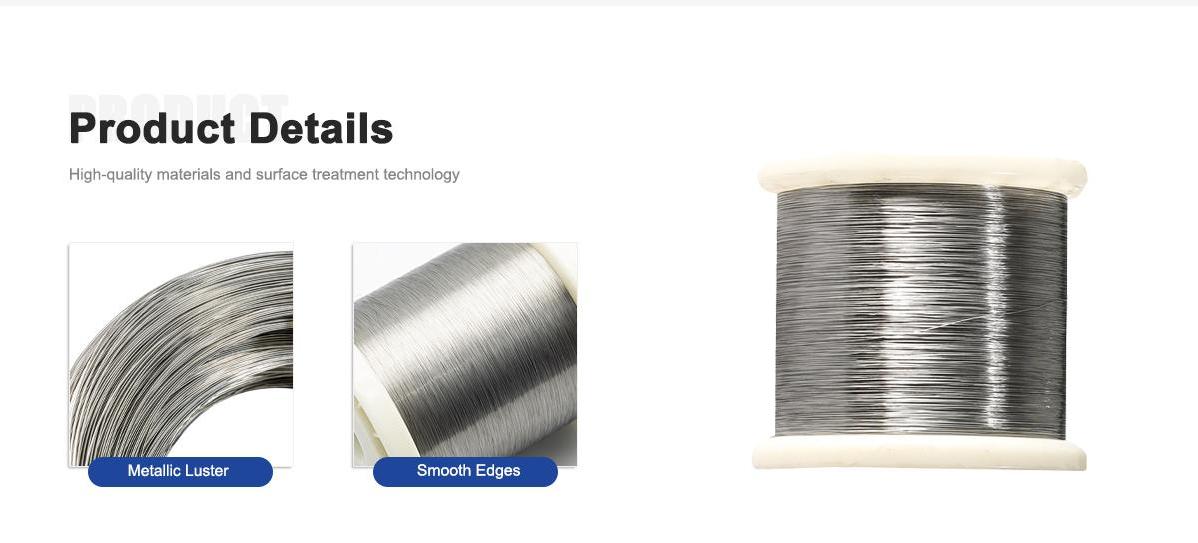

Product Details

Inconel X-750 wire is an exceptional high-performance alloy known for its superior resistance to heat, oxidation, and corrosion, making it an ideal choice for use in nuclear power plants. This nickel-based superalloy is designed to withstand extreme temperatures and mechanical stresses, ensuring reliability and safety in critical applications. Due to its excellent properties, Inconel X-750 wire is widely used in various industries, including aerospace, chemical processing, and particularly in nuclear power plants, where durability and performance are of paramount importance.

Item | Inconel 600 | Inconel X750 | Inconel 825 | |||||

C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

Fe | 6-10 | rest | ≤3 | rest | 7-11 | rest | 5-9 | ≥22 |

P | ≤0.015 | ≤0.02 | ≤0.015 | -- | -- | -- | -- | -- |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

Cu | ≤0.5 | ≤1 | -- | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

Ni | ≥72 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

Co | -- | -- | 10-15 | ≤10 | -- | ≤1 | ≤1 | -- |

Al | -- | 1-1.7 | 0.8-1.5 | ≤0.8 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

Ti | -- | -- | ≤0.6 | ≤1.15 | -- | -- | 2.25-2.75 | 0.6-1.2 |

Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

Nb+Ta | -- | -- | -- | 4.75-5.5 | -- | 4.75-5.5 | 0.7-1.2 | -- |

Mo | -- | -- | 8-10 | 2.8-3.3 | -- | 2.8-3.3 | -- | 2.5-3.5 |

B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

Shape | Size (mm) |

Wire | 0.02-7.50 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Customized |

Sheet/Plate | Customized |

High-Temperature Resistance: Inconel X-750 wire is capable of withstanding temperatures up to 2200°F (1204°C) without losing its strength or structural integrity, making it perfect for high-temperature environments, such as nuclear reactors.

Corrosion and Oxidation Resistance: The alloy’s exceptional resistance to oxidation and corrosion ensures long-term durability and performance in environments where other materials would degrade rapidly.

Excellent Fatigue and Thermal-Cyclic Properties: Inconel X-750 maintains its mechanical strength and resistances in cyclic and thermal conditions, making it ideal for high-stress applications such as nuclear power plant reactors, gas turbines, and heat exchangers.

Versatility: This alloy is available in various forms, including wire, bars, and sheets, which can be tailored for specific applications in nuclear plants and other industries.

Long-Term Durability: The alloy’s ability to resist stress-corrosion cracking and creep ensures reliable and extended service life, making it indispensable in demanding applications.

Inconel X-750 wire is predominantly used in nuclear power plants due to its ability to endure extreme conditions, ensuring both safety and efficiency in energy generation. Some of the key applications include:

Fuel Rods:

Inconel X-750 wire is used in the construction of fuel rods for nuclear reactors. Its high-temperature resistance and corrosion resistance ensure the integrity of the fuel rods during the reactor's operation, even under intense radiation.

Reactor Structural Components:

The alloy is employed in various structural components within the reactor, including core support structures, control rod drive mechanisms, and reactor pressure vessels, where it provides the necessary strength and resistance to thermal cycling.

Heat Exchangers:

Inconel X-750 wire is also used in heat exchangers within nuclear plants. Its superior ability to withstand both high temperatures and corrosive environments ensures the efficient transfer of heat between fluids, contributing to the overall efficiency of the power plant.

Turbine Blades and Exhaust Systems:

For nuclear power plants that utilize turbine generators, Inconel X-750 wire is used to manufacture turbine blades and exhaust components that are exposed to high-temperature gases, ensuring reliable performance over extended periods.

Steam Generator Tubes:

Inconel X-750 wire is used in steam generator tubes, which are subjected to extreme temperatures and pressures. The alloy's resistance to corrosion and high strength ensures the safety and longevity of the steam generation process.

Instrumentation and Sensors:

The alloy is also utilized in nuclear instrumentation and sensors, providing reliable and accurate measurements under harsh conditions, ensuring safe and efficient plant operations.

Enhanced Performance: The alloy’s resistance to high temperatures and oxidative environments ensures reliable and continuous operation in nuclear reactors, where performance is critical.

Durability: Inconel X-750 wire's resistance to thermal cycling, creep, and stress corrosion cracking allows for long service life, reducing the frequency of maintenance and replacements.

Safety: By ensuring that critical components like fuel rods, reactor pressure vessels, and heat exchangers maintain their structural integrity, Inconel X-750 helps maintain a safe operational environment in nuclear power plants.

Corrosion Resistance: Inconel X-750 provides excellent resistance against the highly corrosive effects of steam, water, and other aggressive media commonly found in nuclear reactors.

Flexibility: The alloy is available in a variety of forms and sizes, including wire, bars, and sheets, providing versatility for different applications in the nuclear sector.

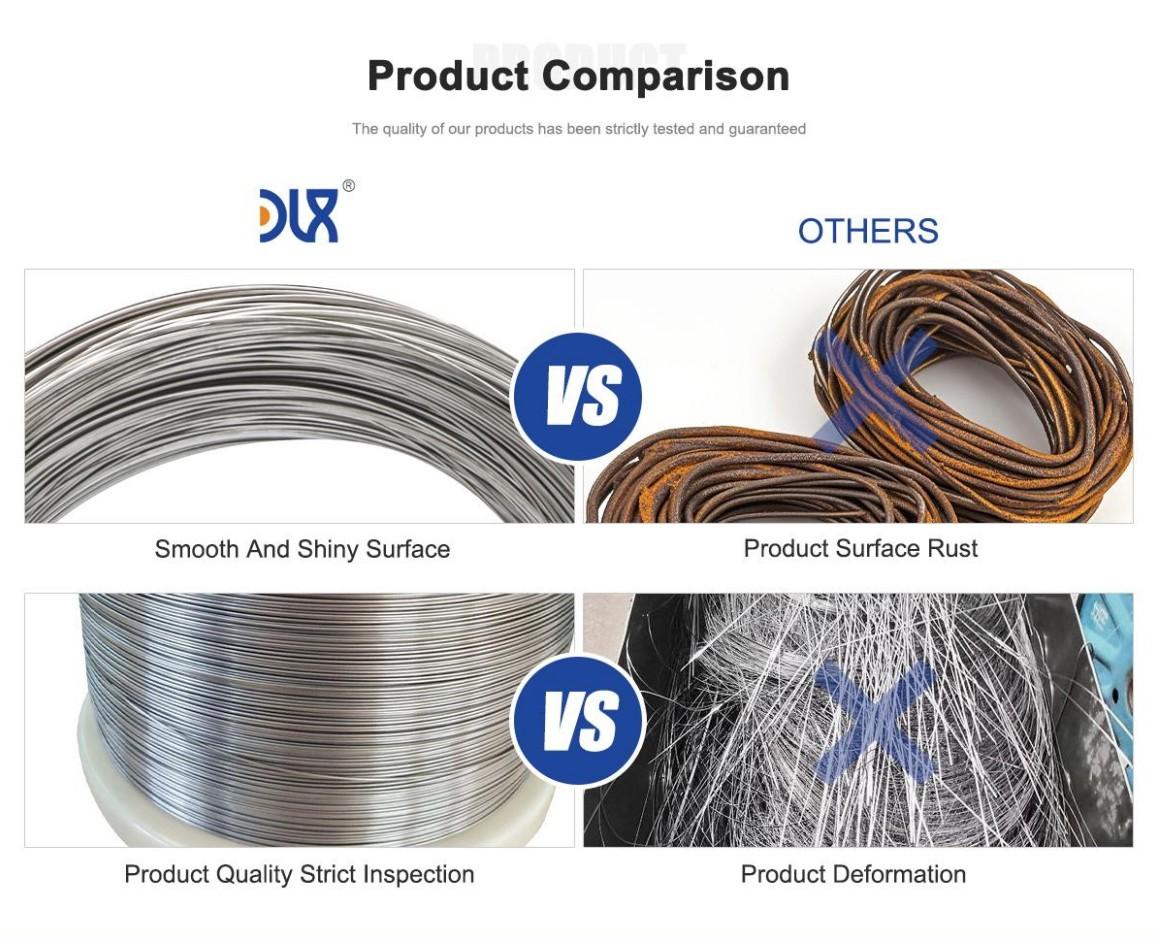

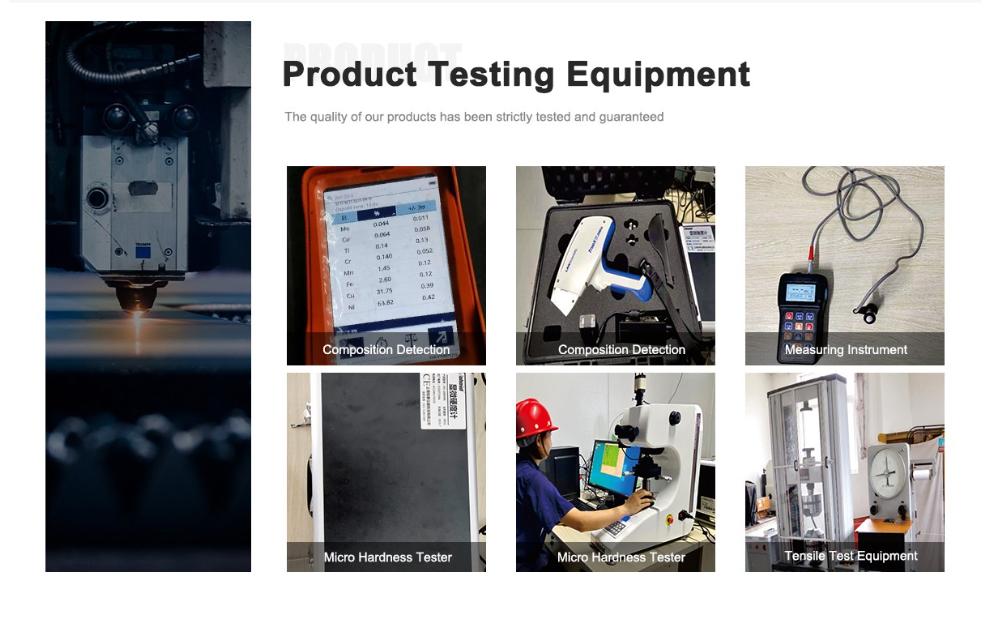

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got ISO9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, Precision Alloy , FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

1. What is the maximum temperature that Inconel X-750 wire can withstand?

Inconel X-750 wire can withstand temperatures up to 2200°F (1204°C), making it suitable for high-temperature applications in nuclear power plants, gas turbines, and heat exchangers.

2. Is Inconel X-750 wire resistant to corrosion?

Yes, Inconel X-750 wire exhibits excellent resistance to oxidation and corrosion, even in extreme environments, which is why it is used in nuclear reactors and chemical processing plants.

3. What are the main applications of Inconel X-750 wire in nuclear power plants?

Inconel X-750 wire is primarily used in nuclear fuel rods, reactor structural components, heat exchangers, turbine blades, steam generator tubes, and instrumentation.

4. What is the composition of Inconel X-750 wire?

Inconel X-750 wire is primarily composed of nickel, chromium, iron, and other elements that provide its high-temperature resistance, strength, and corrosion resistance.

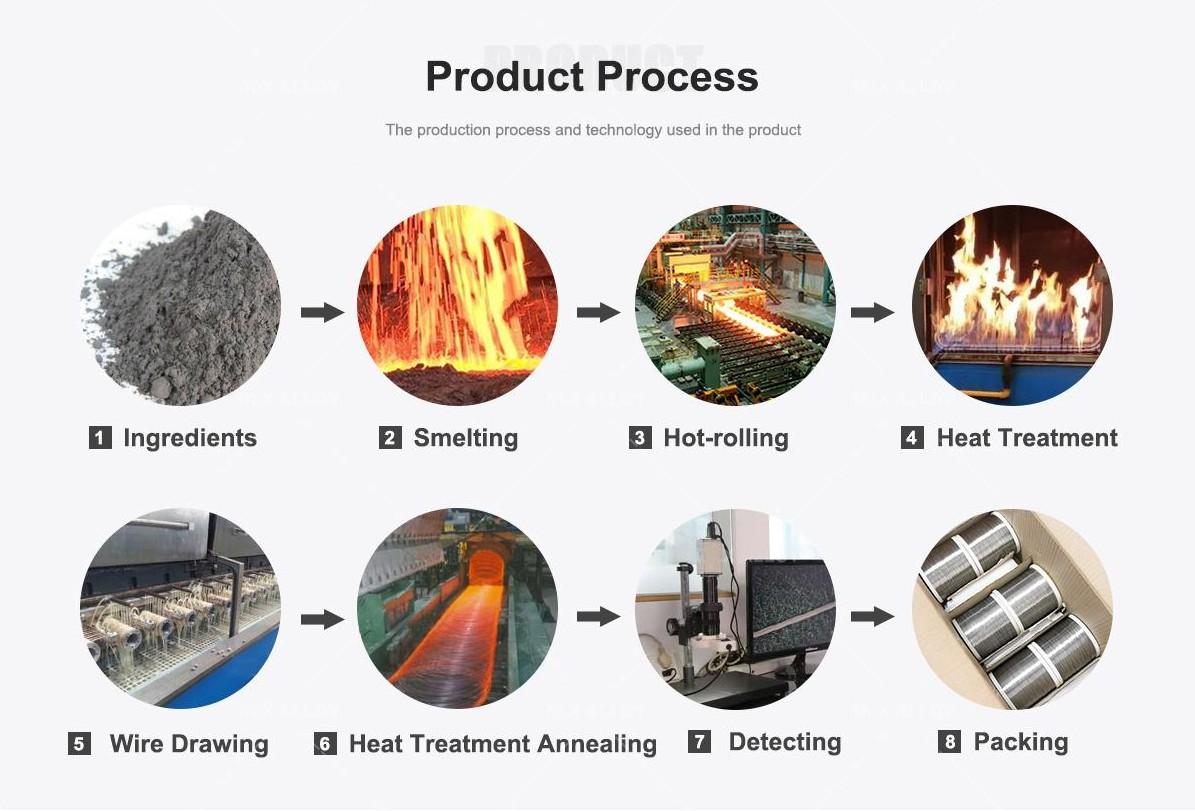

5. How is Inconel X-750 wire fabricated?

Inconel X-750 wire can be fabricated using conventional wire drawing and machining methods to suit specific applications, ensuring versatility and reliability in various sectors.

6. Can Inconel X-750 wire be used in other industries besides nuclear power?

Yes, Inconel X-750 wire is also widely used in aerospace, chemical processing, and power generation, thanks to its high strength, heat resistance, and corrosion resistance.