Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Nitinol Pipe

Product Details

Nickel Titanium (also known as Nitinol or NiTi) is in the unique class of shape memory alloys. A thermoelastic martensitic phase transformation in the material is responsible for its extraordinary properties.

Nitinol alloys are typically made of 55%-56% Nickel and 44%-45% Titanium. Small changes in composition can significantly impact the properties of the material.

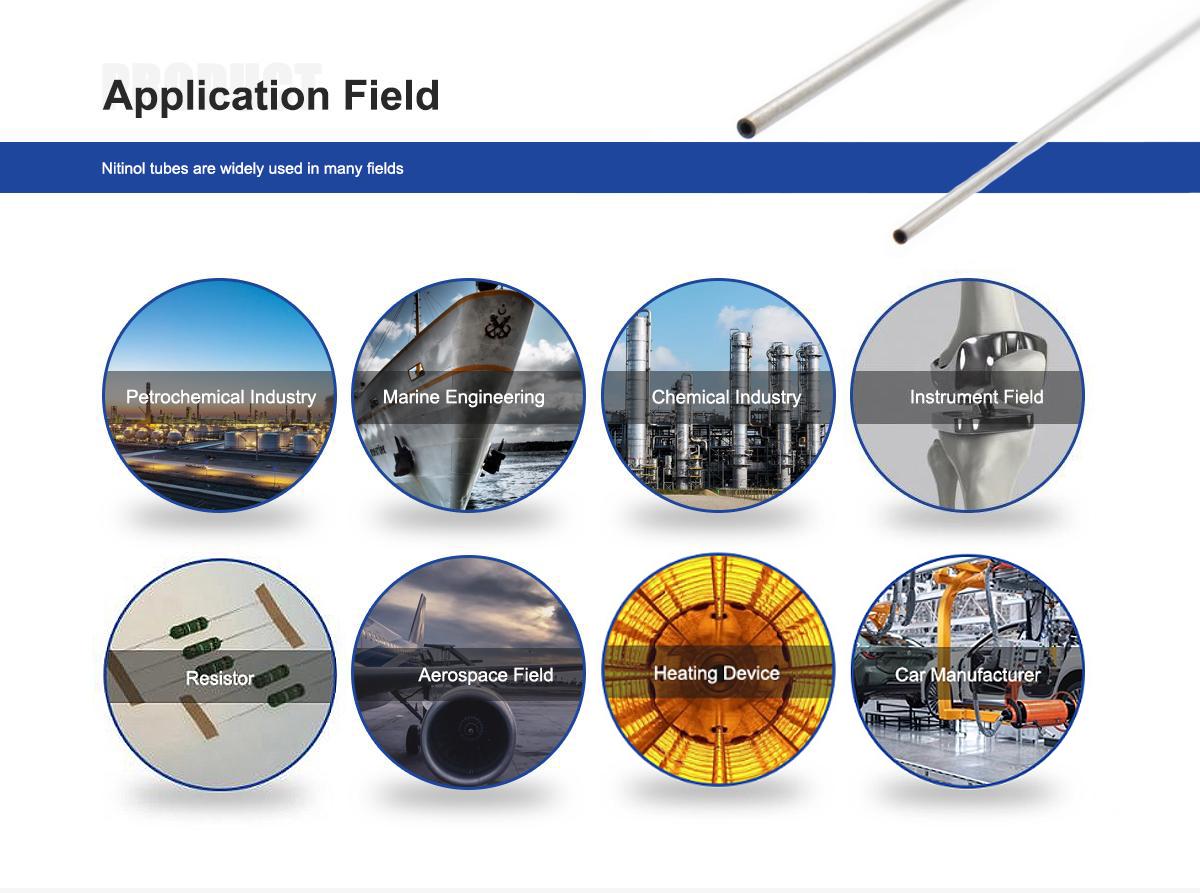

Our superelastic Nitinol tube meets stringent industry standards, ensuring high purity and performance. It is ideal for applications requiring flexibility, durability, biocompatibility, and corrosion resistance, such as medical devices, aerospace components, and industrial tubing. Superelastic Nitinol tube offers exceptional resilience, making it a preferred choice for dynamic environments where the Nitinol tube must withstand repeated stress without permanent deformation.

Returns to its original shape upon heating, ideal for dynamic aerospace applications like deployable structures.

Maintains flexibility and resilience under stress, perfect for aerospace NiTi tube in high-vibration environments.

Performs reliably in harsh environments, including seawater, chemicals, and extreme aerospace conditions, making it a top choice for corrosion-resistant NiTi tube.

Meets ASTM F2063 standards, safe for surgical implants and medical devices utilizing superelastic Nitinol tube.

Tailored to specific requirements, with black or silver surface finishes for versatile Nitinol tube applications.

Withstands repeated deformation-heating cycles, ensuring long-term performance in superelastic Nitinol tube.

Leveraging exceptional strength-to-weight ratio, biocompatibility, and extreme-environment resilience, superelastic Nitinol tube is irreplaceable in:

Used in catheters, stents, and endoscopic components due to biocompatibility and shape memory of Nitinol tube.

Employed in flexible tubing and actuators for its lightweight and high-strength properties in superelastic Nitinol tube.

Ideal for corrosion-resistant conduits in seawater environments, showcasing the durability of Nitinol tube.

Utilized in heat-shrink tubing and sensors for its durability and shape memory effect with superelastic Nitinol tube.

Applied in robotics, hydraulic systems, and precision tubing for actuators and reliable components in Nitinol tube.

| Name | Grade | Transformation Temperature AF | Form | Standard |

Shape Memory Nitinol Alloy | Ti-Ni-01 | 20 °C~ 40 °C | tube Wire, bar, plate

| Customer specified or Industry standard |

Ti-Ni-02 | 45 °C~ 90 °C | |||

Superelastic Nitinol Alloy | TiNi-SS | -5 °C~ 5 °C | ||

Low Temperature Superelastic Nitinol Alloy | TN3 | -5°C~ -15°C -20°C~ -30°C | ||

TNC | ||||

Medical Nitinol Alloy | TiNi-SS | 33 ± 3 °C | ASTM F2063 |

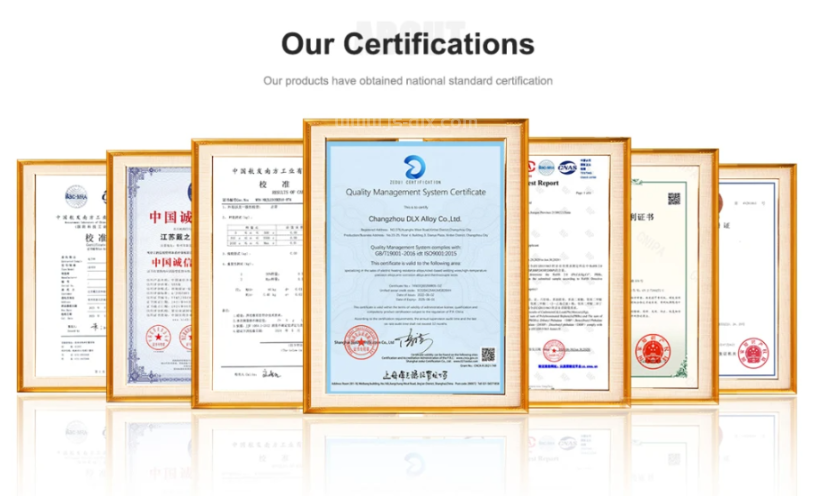

Founded in 2002, CHANGZHOU DLX ALLOY CO., LTD is a leading manufacturer specializing in the research and production of specialized alloy materials. Our factory has earned both the ISO9001 International Quality Management System Certificate and SGS Certification, affirming our commitment to high standards of quality.

We are experts in the entire alloy production process, including melting, drawing, heat treatment, finishing, and rigorous testing. Our product range includes nickel-based, copper-based, and iron-based alloys, such as super alloys, welding materials, anti-corrosion alloys, precision alloys, FeCrAl alloys, NiCr alloys, CuNi alloys, and thermocouples. These are available in various forms including wire, strip, ribbon, bar, tube, and plate.

Q:What is your working time?

A:Monday-Saturday : 7:30AM-17:00PM (Beijing time, GMT+08.00)

Q:Do you provide free samples?

A:Yes, we can provide a free sample for testing,buyer should bear all the shipping costs.

Q:What is your payment terms?

A:T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

Q:What is the lead time?

A:Usually sample lead time is 7 days after payment has been confirmed.

Previous article:Aerospace NiTi Tube Corrosion-Resistant Shape Memory Alloy

Next article:Nitinol Tube Manufacturer | Precision Engineering Solutions