Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Nitinol Rod

Product Details

Product Description

Nitinol Rod s are made mostly of nickel and titanium. They have a special ability to remember their original shape and return to it, even after being bent or twisted. This is because the material can change its inner structure in a reversible way. Nitinol rods are also extremely flexible, able to be deformed a lot without permanently changing shape. The mix of nickel and titanium can be adjusted to control when these shape changes happen, making Nitinol very versatile. Importantly, Nitinol is safe to use in the body, so it can be used in medical devices. These unique properties make Nitinol rods useful in many industries, from medical to aerospace, where their shape memory and flexibility provide important benefits.

Applications

Nitinol rods, with their unique shape memory and superelastic properties, find applications across a wide range of industries:

Applications:

- Medical devices: Stents, orthodontic wires, guidewires, medical implants

- Aerospace: Actuators, structural components, couplings

- Consumer products: Eyeglass frames, cell phone antennas, toys

- Industrial: Couplings, valves, fasteners, damping devices

1. Shape Memory Effect:

- Nitinol rods can "remember" and return to their original shape after being deformed.

- This is enabled by a reversible phase transformation in the crystal structure.

2. Superelasticity:

- Nitinol exhibits exceptional elasticity, allowing it to undergo large, reversible deformations.

- This is caused by a stress-induced phase transformation between austenite and martensite.

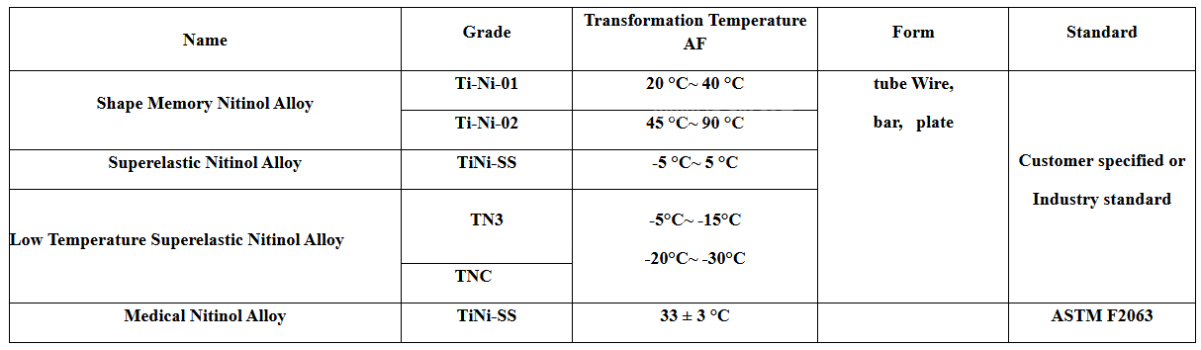

3. Tunable Transformation Temperatures:

- The temperatures at which the austenite-martensite phase transformation occurs can be adjusted by modifying the nickel-titanium composition.

4. Biocompatibility:

- Nitinol is highly biocompatible, making it suitable for medical and implantable applications.

These unique properties allow Nitinol rods to be used in a wide range of applications that require materials with shape memory, superelasticity, and customizable transformation temperatures.

The ability to tailor the composition further expands the versatility of Nitinol rods across diverse industries.

Detailed Photos

We can customize the thickness of the Nitinol rods to precisely match your specific requirements.

Prior to shipment, we will provide you with detailed photographs showcasing the exact dimensions, ensuring the measurements meet your expectations.

This step allows you to thoroughly review and confirm the product specifications, guaranteeing that the final item perfectly aligns with your needs.

To ensure the Nitinol rods arrive in pristine condition, we will securely package them using sturdy wooden pallets or crates.

This durable packaging method effectively shields the product from any potential damage during transit,

giving you the confidence and peace of mind that you will receive a high-quality product as expected.

Product Parameters

The composition of Nitinol (Nickel Titanium) is as follows:

Nitinol is an alloy primarily composed of two metallic elements:

1. Nickel (Ni):

- Nitinol typically contains 50-60% nickel.

- Nickel provides the shape memory and superelastic properties to the alloy.

2. Titanium (Ti):

- Nitinol contains 40-50% titanium.

- Titanium contributes to the biocompatibility and corrosion resistance of the alloy.

The exact nickel-to-titanium ratio can be adjusted to fine-tune the transformation temperatures and other properties of the Nitinol alloy.

Small amounts of other elements, such as copper or iron, may also be added in some cases to further optimize the material's characteristics.

This customizable composition is a key advantage of Nitinol, as it allows the material to be tailored for specific applications and requirements.

The ability to precisely control the nickel and titanium percentages is what gives Nitinol its unique shape memory, superelasticity, and biocompatibility - properties that make it a versatile material for use in a wide range of industries.

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

If any requirements and questions, please feel free to reach:

Sophie Wang | Sales +86 19906119641

International Sales Depart.

Jiangsu Victory Technology Co., Ltd

A: NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu