Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Nitinol Wires

Product Details

Our Nitinol Wire is engineered specifically for high-cycle, precision applications in industrial automation. It leverages the unique superelasticity and shape memory effect of Nickel-Titanium alloy, combined with a specialized processing technique that significantly enhances its fatigue life. This wire can undergo millions of repeated stress cycles without failure, making it an ideal smart material for actuators, sensors, and repetitive motion mechanisms.

Exceptional Fatigue Resistance (>10⁷ cycles): Outperforms conventional springs and other metals in high-frequency applications.

Large Superelastic Strain (Up to 8%): Provides a wide range of motion and force in a compact form factor.

Constant Force Output: Maintains a nearly constant force over a large strain range, ideal for precise actuation.

Excellent Corrosion Resistance: Performs reliably in harsh environments.

Biocompatible Options Available: Suitable for applications in medical devices and food processing automation.

Laboratory Equipment: NiTi is employed in sensitive laboratory instruments that require precision and reliability for experimental setups.

Teaching Aids: The properties of NiTi are used in educational models to demonstrate concepts of physics and material science.

Art and Design Applications

Sculptural Materials: Artists are exploring NiTi for sculptures that can change shape or respond to environmental factors, creating dynamic art pieces.

Innovative Designs: The alloy’s versatility allows designers to create unique furniture and decor that incorporates movement and adaptability.

Detailed Photos

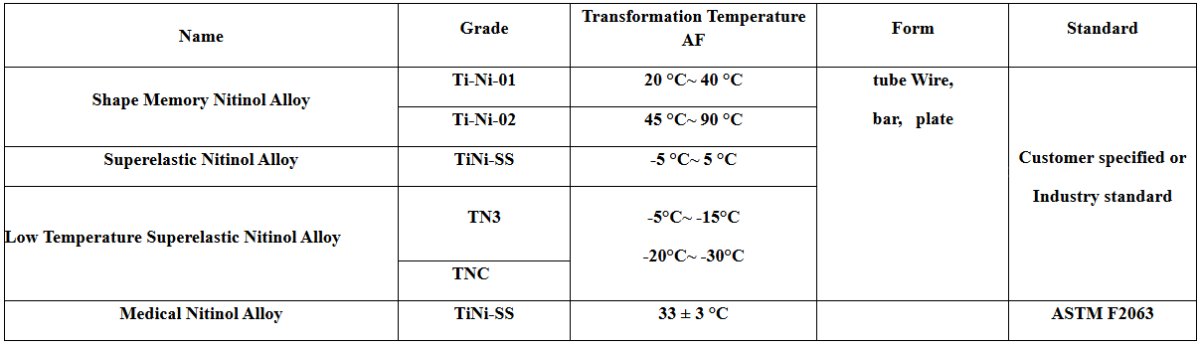

Product Parameters

Recommended products

Company Profile

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

If any requirements and questions, please feel free to reach:

Sophie Wang | Sales +86 19906119641

International Sales Depart.

Jiangsu Victory Technology Co., Ltd

A: NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu

FAQ

Previous article:Wear-Resistant NiTi for Innovations in Manufacturing

Next article:Self-Healing NiTi for Exploring Future Materials