Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Nitinol Wires

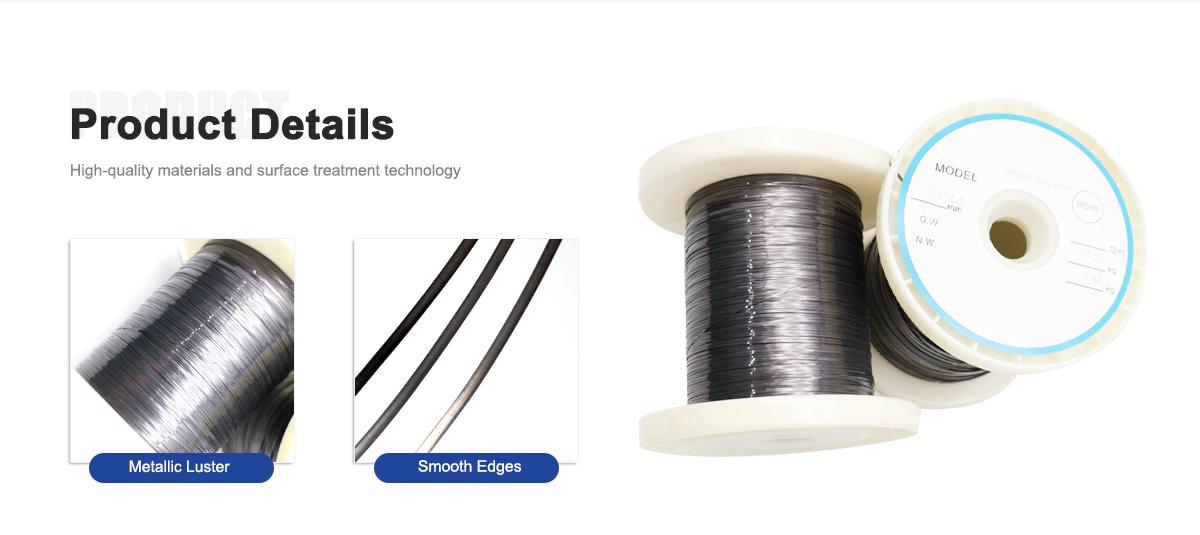

Product Details

Nitinol Wire, a high-performance nickel-titanium shape memory alloy (NiTi), is engineered for exceptional shape recovery, superelasticity, and durability in demanding environments. Combining near-equal atomic ratios of nickel (55%-56%) and titanium (44%-45%), this alloy delivers unmatched biocompatibility, corrosion resistance, and mechanical strength, making it a cornerstone for innovations in medical devices, aerospace systems, and advanced manufacturing.

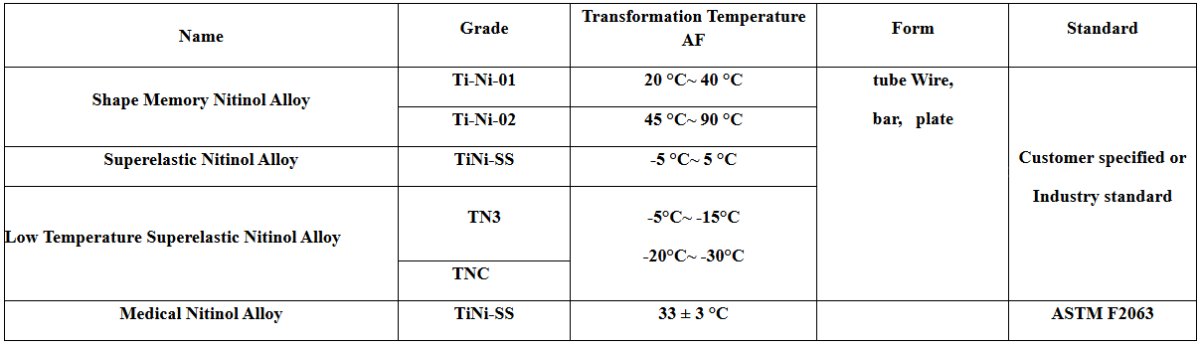

Grade: NiTi (Superelastic and Shape Memory grades)Purity: > 99.7%Density: 6.45 g/cm³Wire Diameter: 0.1mm - 10mmProcessing Technique: Cold Rolled, Hot Rolled, Vacuum AnnealedSurface: Polished, Bright, OxidedMelting Point: 1310°CTransition Temperature: -20°C to 80°C (customizable)Condition: Annealed, Straight Wire or CoilMinimum Order Quantity (MOQ): 1 kgDelivery Time: 5-20 days for small orders, 60 days for large orders

Nitinol wire can return to its pre-set shape when heated above its Austenite finish temperature (Af), offering >8% strain recovery for actuators and deployable structures.

Exhibits extraordinary recoverable strains and kink resistance, ideal for flexible medical devices and dynamic applications.

Zero tissue rejection and no metallic ion release, making it perfect for medical implants like stents and orthodontic wires.

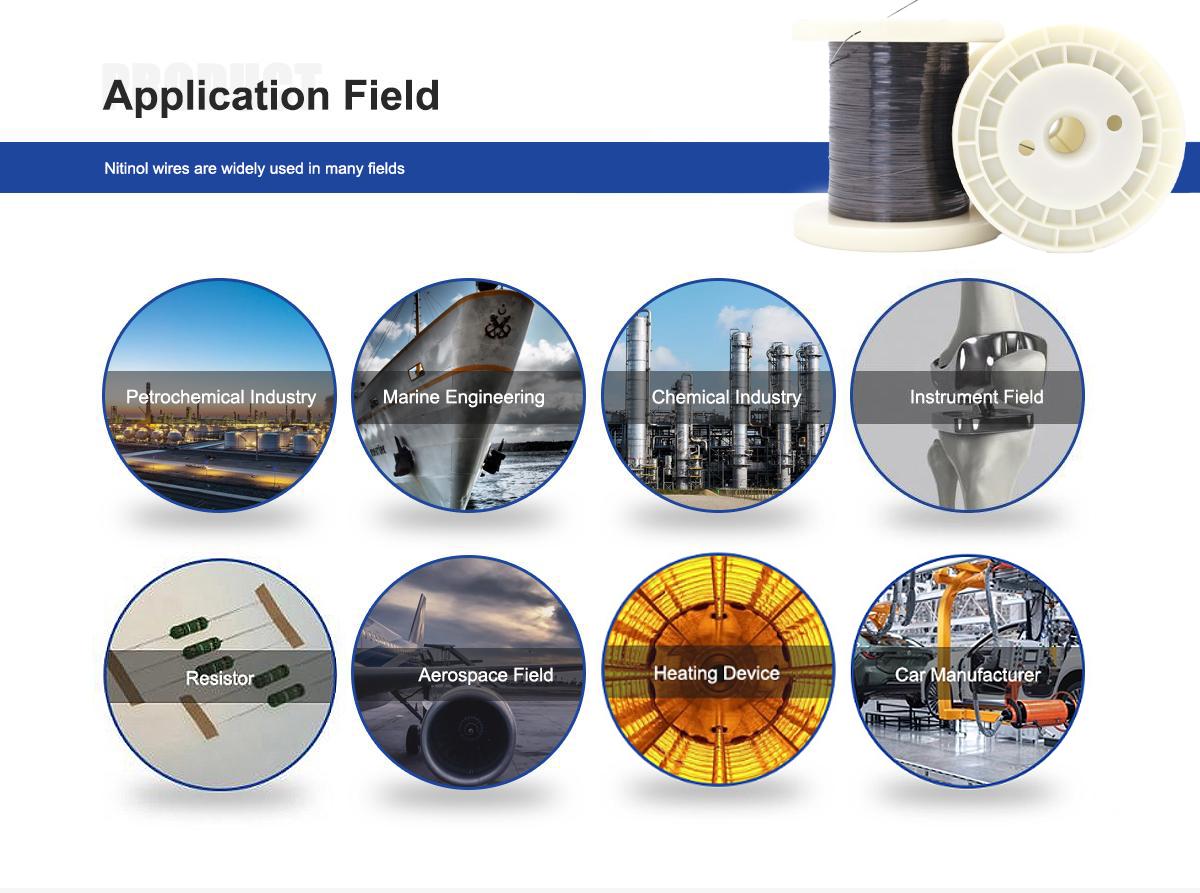

Resists corrosion in harsh environments, including seawater, acids, and alkalis, ensuring >10x lifespan compared to stainless steel.

Matches the strength of alloy steel while being 43% lighter, enabling lightweight designs in aerospace and wearables.

Maintains performance from cryogenic (-250°C) to elevated temperatures (600°C), suitable for extreme environments.

Supports ultra-fine wire drawing (down to Ø0.01mm), braiding, and additive manufacturing for complex applications.

Wearable Technology: NiTi’s flexibility allows for the creation of comfortable smartwatches and fitness trackers that conform to the user’s wrist. This adaptability enhances user experience, making wearable technology more appealing.

Smart Fabrics: Integration of NiTi into textiles enables the development of clothing that can change properties based on environmental conditions, such as temperature regulation, offering enhanced comfort and functionality.

Self-Healing Materials: Research into NiTi’s potential for self-healing materials is promising. These materials could revolutionize product design, allowing items to recover from damage, thus extending their lifespan and reducing waste.

Eco-Friendly Solutions: NiTi is being explored for applications in renewable energy technologies, such as solar panels that can adjust their angle for optimal sunlight exposure, enhancing energy efficiency in sustainable solutions.

Detailed Photos

Product Parameters

Recommended products

Company Profile

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

If any requirements and questions, please feel free to reach:

Sophie Wang | Sales +86 19906119641

International Sales Depart.

Jiangsu Victory Technology Co., Ltd

A: NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu

Previous article:Unique Nickel-Titanium Wire for Artistic Creations

Next article:Smart NiTi for Breakthroughs in Bioengineering