Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Nitinol Wires

Product Details

Product Description

NiTi wire is a unique alloy made from nickel and titanium, renowned for its extraordinary properties that are crucial in numerous industries, including healthcare, aerospace, and electronics. A defining characteristic of this wire is its shape memory effect, which allows it to revert to a designated shape when heated, making it highly versatile for engineering applications. Furthermore, its superelasticity enables it to undergo significant bending and twisting without enduring permanent changes, which is particularly advantageous in orthodontics, where it is used in archwires or springs to deliver consistent forces and ensure greater patient comfort.

Applications

Advantages:

Shape Memory Technology: NiTi screws can revert to their original shape when heated, providing unique solutions for diverse applications.

Superelastic Features: They can tolerate large deformations without permanent changes, making them adaptable for various uses.

Corrosion Resistance: Their strong resistance to corrosion ensures reliability and durability in harsh environments.

Biocompatibility: NiTi screws are safe for use in medical devices and implants, ensuring patient safety.

Weight Efficiency: The lightweight design contributes to overall system efficiency, especially in aerospace and automotive sectors.

Applications:

Healthcare Technology: Widely used in surgical implants and devices, providing effective fastening solutions.

Aerospace Engineering: Critical in the manufacturing of lightweight structures that improve performance.

Automotive Applications: Found in various automotive components requiring high durability and thermal resistance.

Energy Production: Effective in oil and gas industry applications, where they endure severe conditions.

Robotic Systems: Essential in developing flexible, adaptive robotic systems that can perform complex tasks.

Detailed Photos

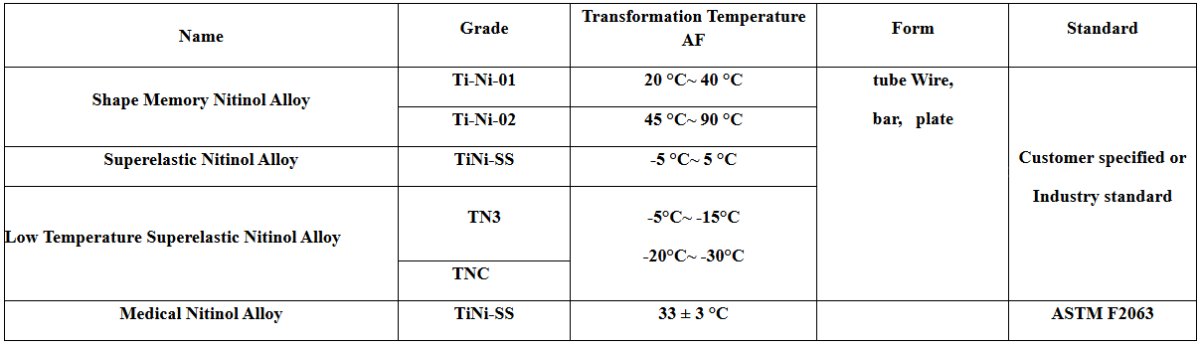

Product Parameters

Recommended products

Company Profile

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

If any requirements and questions, please feel free to reach:

Sophie Wang | Sales +86 19906119641

International Sales Depart.

Jiangsu Victory Technology Co., Ltd

A: NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu

FAQ

Previous article:Fatigue-Resistant Nitinol Wire for Shipbuilding

Next article:High-Conductivity Nitinol Wire for Battery Technology