Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Nitinol Wires

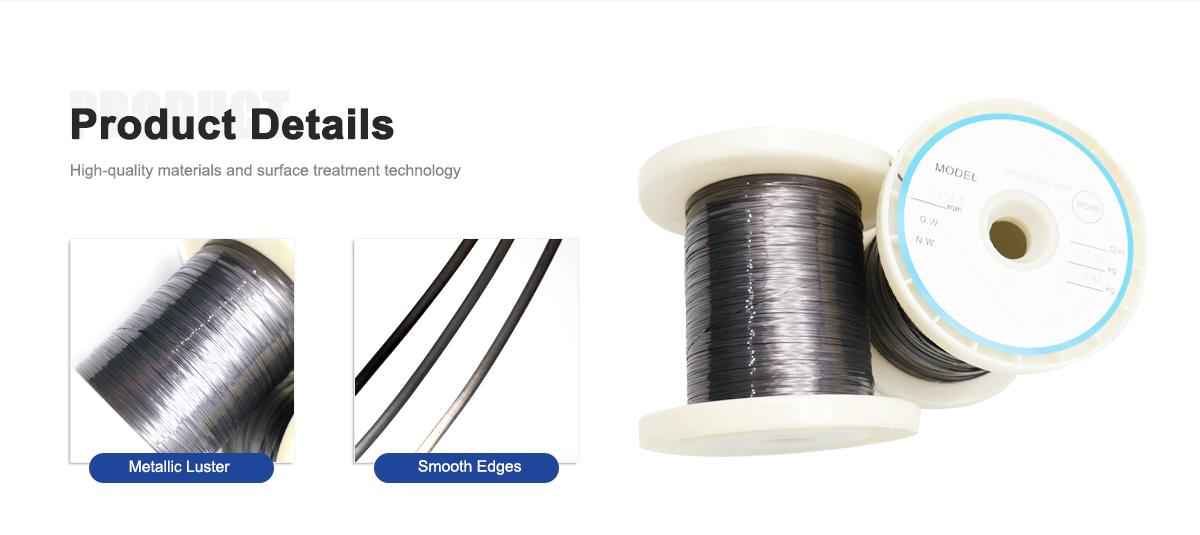

Product Details

Nitinol wire is increasingly recognized as a critical element in advanced wound closure systems, offering a robust and efficient solution for tissue fixation in surgical settings. Its distinctive properties ensure accurate and consistent wound alignment, maintaining the integrity and stability of incision sites throughout the healing journey.

The exceptional qualities of Nitinol play a pivotal role in reducing postoperative complications by supporting optimal tissue repair. Its shape memory functionality and ability to adapt to tissue changes significantly enhance the precision of wound closure, leading to superior surgical results and faster patient rehabilitation.

Shape Memory Effect: Nitinol wire has the unique ability to return to its pre-defined shape when heated above a certain transformation temperature, making it ideal for applications in aerospace, robotics, and medical devices.

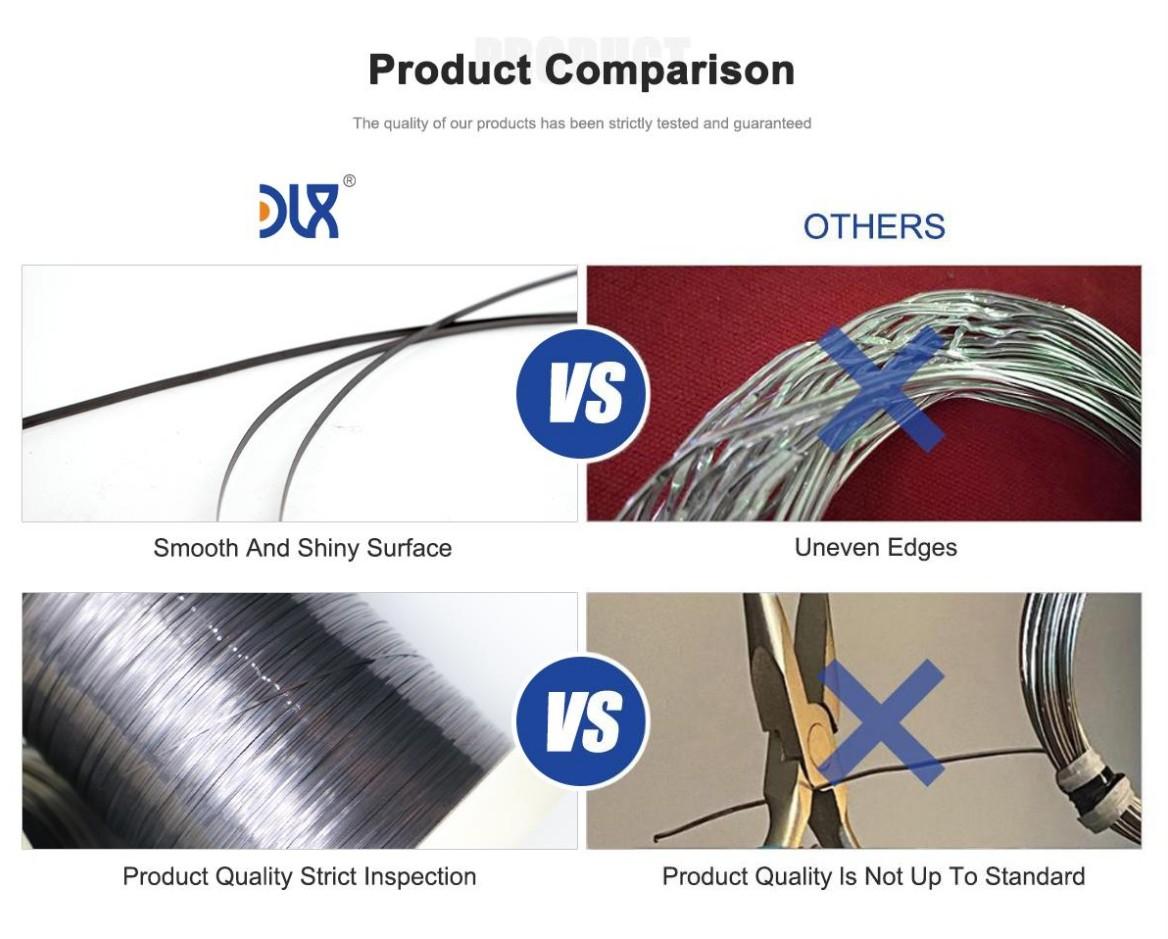

Superelasticity: Nitinol exhibits high recoverable strain, offering excellent kink resistance and the ability to withstand large deformations without permanent damage.

Corrosion Resistance: Nitinol is highly resistant to corrosion, which makes it suitable for use in challenging environments, such as aerospace and medical applications.

Biocompatibility: As a medical-grade material, Nitinol is safe for use in the human body, commonly used in orthodontics, stents, and surgical instruments.

High Mechanical Strength: Nitinol's robust tensile strength ensures reliability and performance even in demanding mechanical and industrial applications.

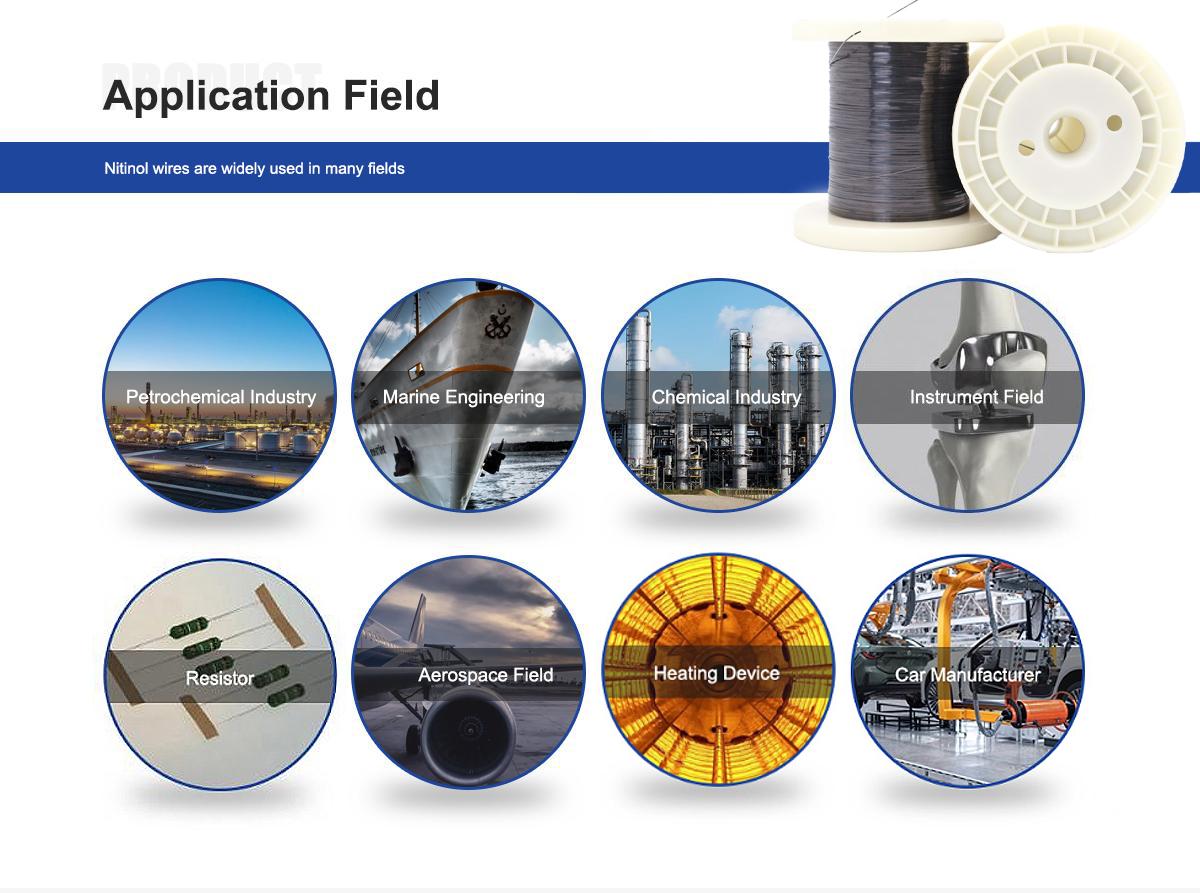

Aerospace: Nitinol wire is widely used in aerospace structures and actuators. Its shape memory and superelastic properties make it perfect for adaptive components, such as deployable structures and flight control systems.

Medical Devices: Nitinol wire is commonly used in medical applications, such as guidewires, stents, and surgical instruments, where its flexibility and biocompatibility provide enhanced patient comfort and efficiency in procedures.

Robotics: Due to its precise motion control and adaptability, Nitinol is employed in robotic actuators and adaptive structures, enabling improved performance in various robotic systems.

Automotive: Nitinol is used in temperature-responsive valves and sensors, enhancing energy efficiency and system reliability.

Eyewear: The alloy is commonly found in flexible eyeglass frames, combining durability with flexibility for user comfort.

Consumer Electronics: Nitinol is used in wearable technology and self-repairing materials, demonstrating its versatility in everyday products.

Lightweight and High Strength: Nitinol's high strength-to-weight ratio makes it ideal for aerospace structures, where weight reduction is critical without compromising on performance.

Temperature Responsiveness: Nitinol’s ability to change shape with temperature changes allows it to be used in adaptive systems, such as wings and control surfaces.

Reduced Mechanical Complexity: Nitinol’s shape memory effect allows for the design of simpler, more reliable systems with fewer mechanical parts.

Enhanced Durability: The superelastic and corrosion-resistant properties of Nitinol contribute to a long-lasting performance even under extreme conditions in aerospace applications.

Precision Actuation: The material's ability to return to a specific shape upon heating enables precise, controlled movements for aerospace mechanisms, improving system efficiency and reliability.

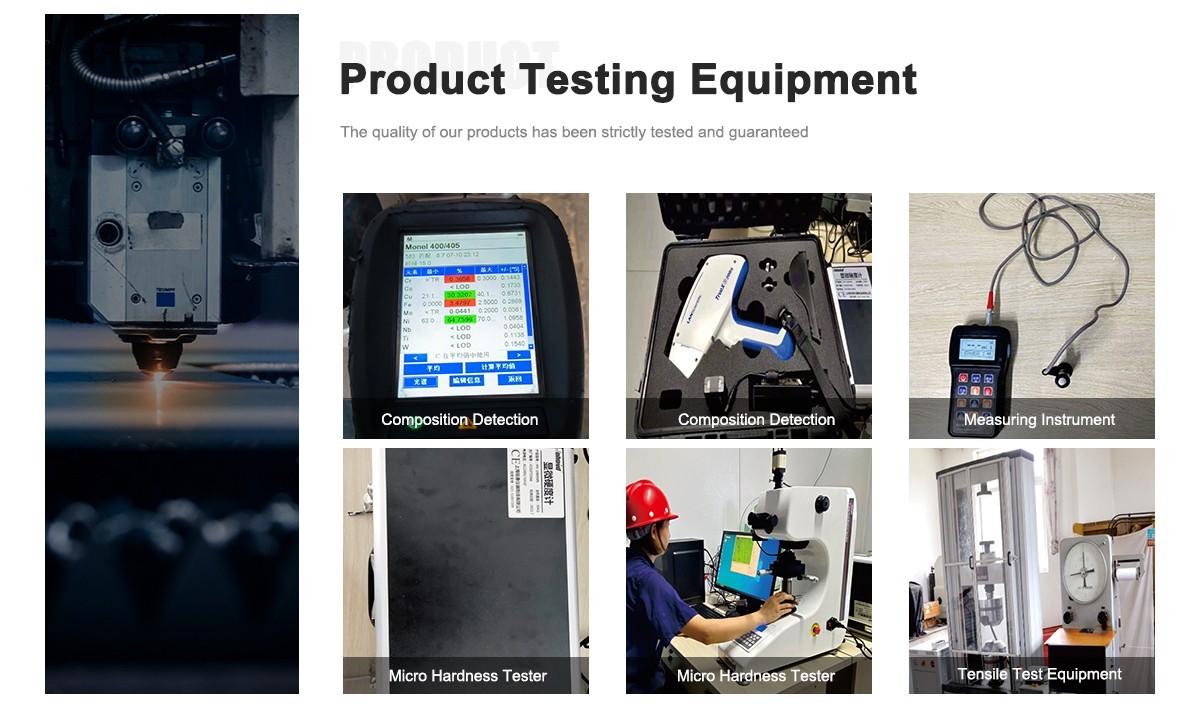

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got ISO9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, Precision Alloy , FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

FAQs

1. How can I contact your company?

WhatsApp: +8619906119641

2. What is your working time?

Monday-Saturday: 7:30 AM - 5:00 PM (Beijing time, GMT+08.00)

Public holidays: May 1-3, Oct 1-7, and Chinese New Year holiday. Please email us during the holiday for any questions.

3. Do you provide free samples?

Yes, we can provide a free sample for testing. The buyer is responsible for shipping costs.

4. What are your payment terms?

T/T, L/C, D/A, D/P, Western Union, MoneyGram, PayPal.

5. What is the lead time?

Sample lead time is typically 7 days after payment confirmation.