Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Nitinol Wires

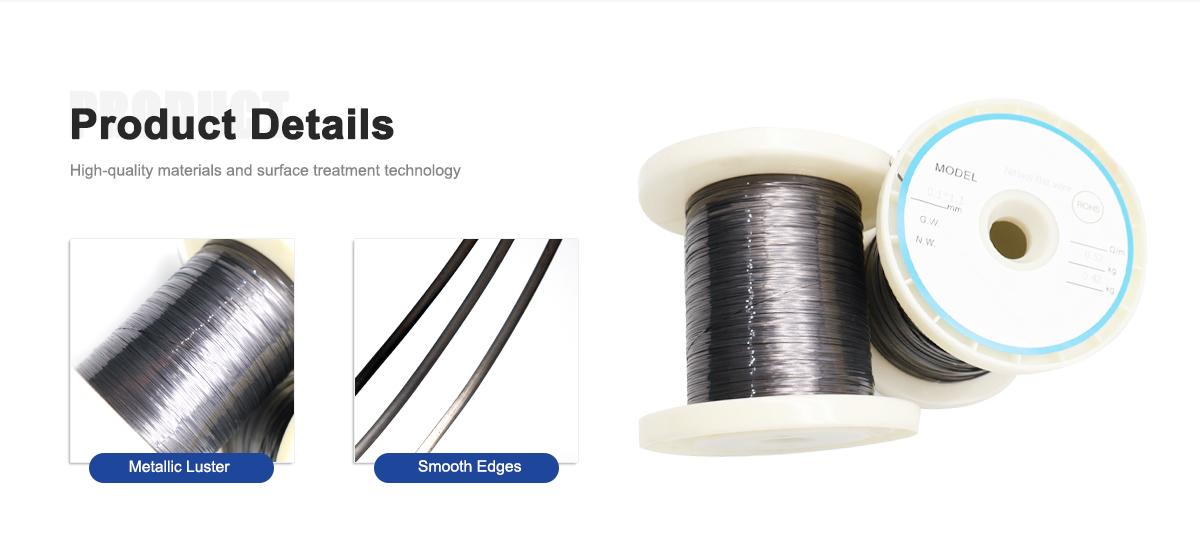

Product Details

Nitinol (Nickel Titanium, NiTi) is a high-performance shape memory alloy (SMA) known for its exceptional mechanical properties, including superelasticity and shape memory effects. Composed of approximately 55%-56% Nickel and 44%-45% Titanium, Nitinol offers unique behavior due to its thermoelastic martensitic phase transformation. This makes it an ideal material for various advanced applications, including those in aerospace, robotics, medical devices, and consumer products.

Due to its ability to return to a pre-defined shape when heated above its transformation temperature, Nitinol is particularly well-suited for components that require precision, adaptability, and durability under extreme conditions.

Superelasticity: Nitinol wire exhibits remarkable superelasticity, meaning it can undergo large strains and return to its original shape when the stress is removed. This makes it highly resilient, especially in applications that require flexibility and durability.

Shape Memory Effect: Nitinol wire has the ability to "remember" its original shape. When heated to a specific temperature, it returns to its predetermined form. This characteristic is widely utilized in various aerospace and industrial applications, including actuators and adaptive structures.

Biocompatibility: In the medical field, Nitinol’s high biocompatibility makes it a preferred material for surgical implants, stents, and other medical devices. It ensures minimal risk of rejection by the body, promoting better healing and comfort for patients.

Corrosion Resistance: Nitinol is highly resistant to corrosion, especially in harsh environments, which is essential for aerospace and marine applications where components are exposed to extreme conditions.

Fatigue Resistance: Nitinol exhibits excellent resistance to fatigue, making it ideal for high-cycle applications like orthodontic wires, guidewires, and flexible eyeglass frames.

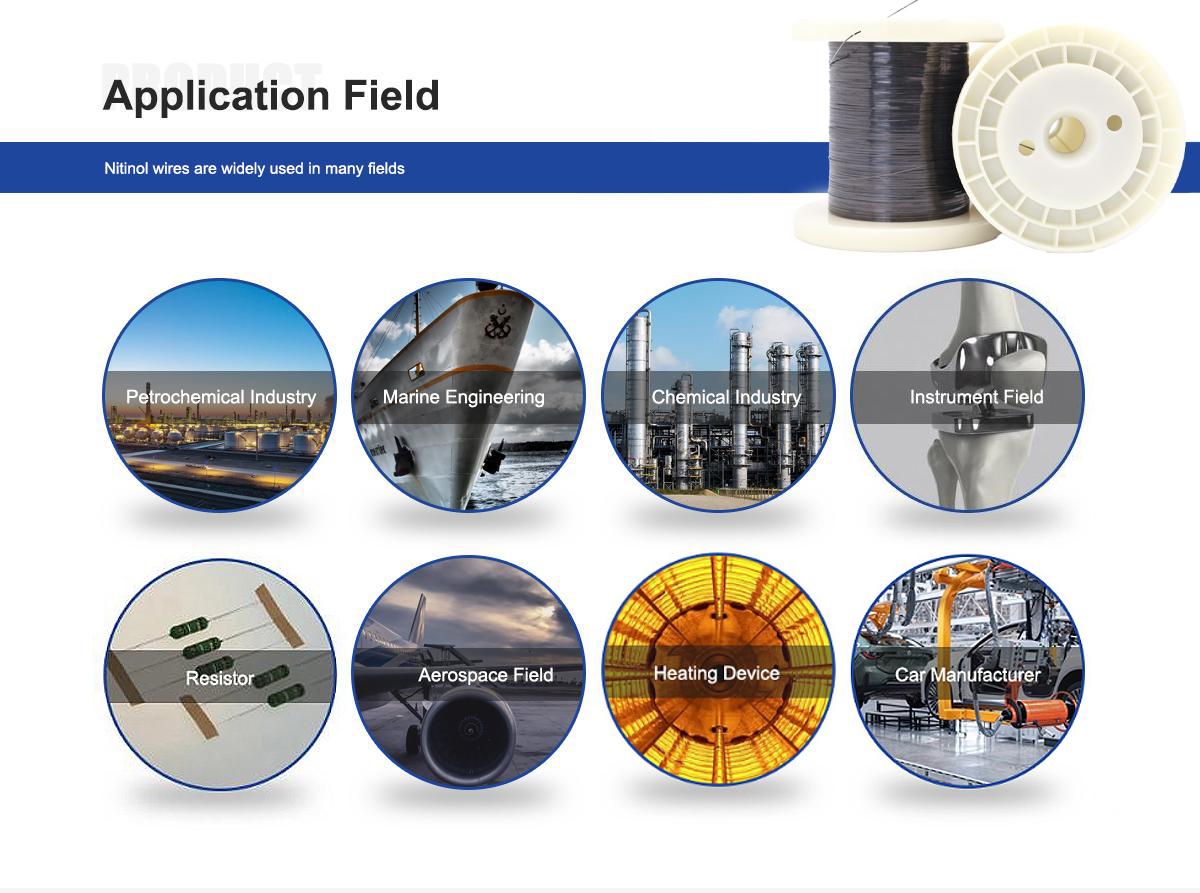

Nitinol wire has a diverse range of applications across industries, thanks to its unique shape memory and superelastic properties. Some of its major uses include:

Aerospace Components: Nitinol is used in adaptive structures, actuators, and aerospace systems that require precision and performance in extreme temperatures and stress conditions. Its superelasticity and shape memory make it ideal for adaptive components that can self-adjust to varying operational conditions.

Medical Devices: Nitinol wire is widely used in orthodontics, guidewires, stents, and minimally invasive surgical instruments. Its flexibility and shape memory properties ensure effective treatment, while its biocompatibility reduces the risk of patient complications.

Robotics and Actuators: In robotics, Nitinol is utilized in actuators and adaptive mechanisms, where its ability to adapt to changes in temperature or stress enables precise movement control and dynamic system responses.

Automotive and Aerospace Sensors: Nitinol’s temperature-responsive characteristics make it an ideal choice for creating temperature-responsive valves and sensors in the automotive and aerospace industries. These components help improve energy efficiency and performance by responding to environmental changes.

Consumer Products: Nitinol wire is also found in everyday products such as eyeglass frames, where its superelasticity allows frames to return to their original shape even after being bent or twisted. Additionally, it is used in wearable technology and self-repairing materials, demonstrating its versatility and widespread appeal.

Adaptability to Extreme Conditions: Nitinol’s ability to return to its original shape under heat makes it highly versatile for applications in both high and low-temperature environments, making it ideal for aerospace and automotive components.

High Precision and Reliability: Nitinol’s superelasticity and shape memory allow for precise motion control and effective actuation in systems requiring high levels of reliability and repeatability.

Long-lasting Performance: Thanks to its resistance to corrosion and fatigue, Nitinol components can endure extended use without degradation, making them cost-effective for industries where longevity is crucial.

Lightweight: Nitinol is a lightweight material, making it particularly beneficial in aerospace applications where reducing weight is essential for improving fuel efficiency and performance.

Q1: What is Nitinol wire?

A1: Nitinol wire is a specialized shape memory alloy composed of Nickel and Titanium. It has unique properties such as superelasticity and the ability to "remember" its original shape when heated, making it ideal for precision applications in aerospace, medical devices, robotics, and more.

Q2: What industries use Nitinol wire?

A2: Nitinol wire is widely used in industries like aerospace, medical, automotive, robotics, and consumer products. Its versatility makes it suitable for applications requiring flexibility, durability, and high performance in extreme conditions.

Q3: What is the difference between superelastic and shape memory Nitinol?

A3: Superelastic Nitinol exhibits high recoverable strain and excellent kink resistance, making it ideal for dynamic applications like orthodontic wires and guidewires. Shape memory Nitinol returns to its pre-defined shape when heated above its transformation temperature, making it perfect for actuators and adaptive components in mechanical systems.

Q4: How does Nitinol perform in aerospace applications?

A4: Nitinol is used in aerospace components due to its ability to adapt to temperature changes and maintain performance in extreme environments. Its shape memory and superelasticity make it ideal for actuators and adaptive structures, offering precision and reliability in aerospace systems.

Q5: Is Nitinol wire biocompatible?

A5: Yes, Nitinol is highly biocompatible, which is why it is commonly used in medical devices such as stents, surgical implants, and guidewires. Its biocompatibility ensures minimal risk of rejection by the body and promotes efficient healing.

Q6: What is the lead time for Nitinol wire?

A6: The lead time for Nitinol wire typically depends on the order quantity and product specifications. Please contact us for precise delivery timelines based on your requirements.