Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

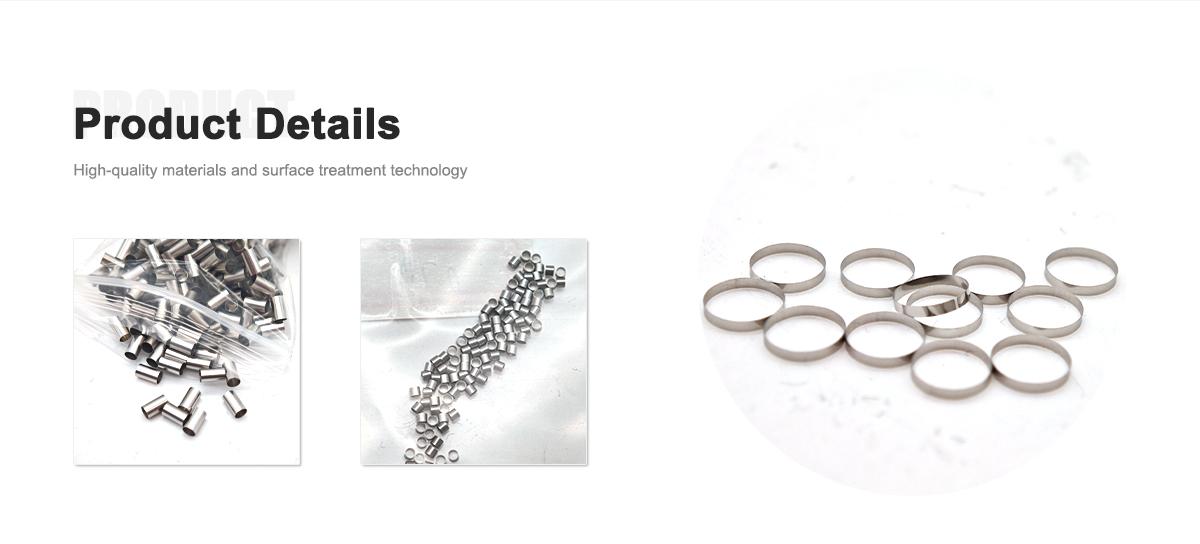

Product Details

Platinum iridium rings are precision-crafted components made from a high-performance alloy blending platinum (Pt) and iridium (Ir), typically in ratios like Pt-20%Ir or Pt-30%Ir, depending on application needs. Renowned for their extraordinary melting point exceeding 2,400°C and exceptional resistance to oxidation, these rings excel in high-temperature sealing and structural roles.

DLX's high-temp platinum iridium rings are produced through advanced metallurgical processes, including powder metallurgy and precision machining, ensuring uniform microstructure and dimensional accuracy. Available in seamless or welded designs, they offer superior hermetic sealing capabilities, making them indispensable in vacuum systems, thermocouples, and electrical contacts. With a density of approximately 21.5 g/cm³ and tensile strength up to 600 MPa, our platinum iridium alloy rings withstand thermal cycling and corrosive media without degradation.

Invest in reliable platinum iridium structural components that enhance system longevity and operational efficiency. DLX guarantees traceability and compliance with ASTM B693 and ISO 9001 standards for every ring.

DLX's Platinum Iridium Rings are designed with cutting-edge metallurgy to outperform conventional materials. Key features include:

Withstands aggressive chemicals and environments, reducing degradation rates by up to 58% compared to pure platinum, ideal for acidic or alkaline exposures.

Enhanced hardness (up to 135 Vickers) from iridium alloying ensures minimal abrasion and extended service life in high-friction applications.

Maintains structural integrity at temperatures over 1700°C, with outstanding oxidation and creep resistance for reliable operation in thermal cycling.

Non-magnetic and hypoallergenic properties make it perfect for medical implants and diagnostic equipment, surpassing stainless steel in corrosion-proofing.

Available in seamless designs with diameters from 5mm to 200mm, tolerances ±0.01mm, and surface finishes for optimal sealing efficiency.

High density (21.5 g/cm³) provides robustness without brittleness, combining platinum's ductility with iridium's strength for versatile use.

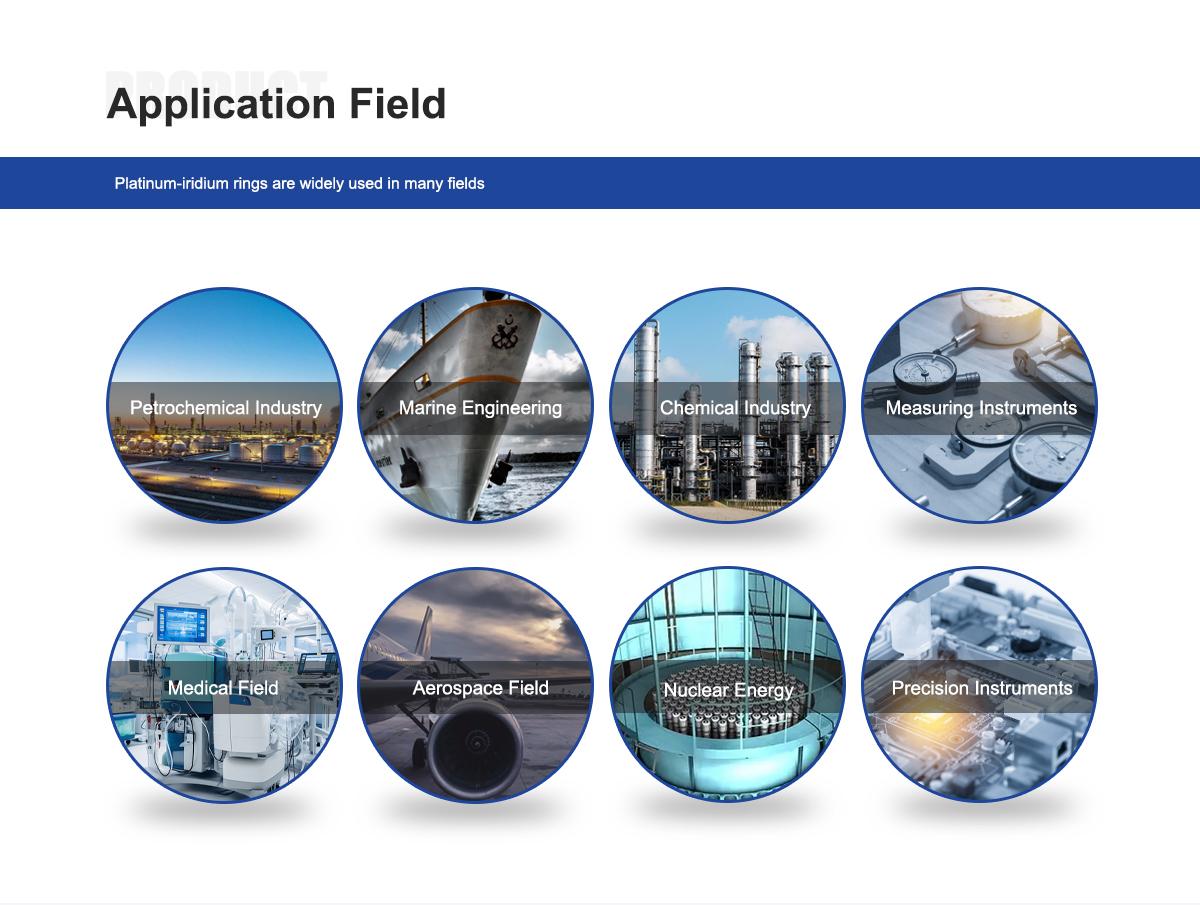

Versatile and robust, the Platinum Iridium Ring excels in diverse sectors where reliability is non-negotiable. Key applications include:

Used as sealing rings in jet engines and rocket nozzles to prevent gas leaks under extreme pressures.

Essential for pacemaker leads, surgical implants, and diagnostic equipment requiring biocompatible seals.

Provides hermetic sealing in vacuum tubes, sensors, and high-vacuum systems to protect sensitive circuits.

Employed in reactors and pipelines for its resistance to aggressive media in petrochemical plants.

Ideal for high-temperature crucibles, thermocouples, and precision instruments in scientific experiments.

Leverages aesthetic appeal and durability for high-end sealing elements in luxury watches and instruments.

At DLX, we don't just supply Platinum Iridium Ring—we deliver excellence backed by decades of alloy expertise. Here's why industry leaders trust us for their high-performance alloy sealing components:

Unrivaled Quality Assurance: ISO 9001 certified with full traceability from raw materials to finished product, ensuring zero defects.

Customization Expertise: In-house design and prototyping for bespoke sizes, alloys, and finishes to fit your exact specifications.

Competitive Lead Times: Rapid production with stock availability for urgent needs, reducing downtime in your operations.

Founded in 2002, CHANGZHOU DLX ALLOY CO., LTD is a leading manufacturer specializing in the research and production of specialized alloy materials. Our factory has earned both the ISO9001 International Quality Management System Certificate and SGS Certification, affirming our commitment to high standards of quality.

We are experts in the entire alloy production process, including melting, drawing, heat treatment, finishing, and rigorous testing. Our product range includes nickel-based, copper-based, and iron-based alloys, such as super alloys, welding materials, anti-corrosion alloys, precision alloys, FeCrAl alloys, NiCr alloys, CuNi alloys, and thermocouples. These are available in various forms including wire, strip, ribbon, bar, tube, and plate.

Q:What is your working time?

A:Monday-Saturday : 7:30AM-17:00PM (Beijing time, GMT+08.00)

Q:Do you provide free samples?

A:Yes, we can provide a free sample for testing,buyer should bear all the shipping costs.

Q:What is your payment terms?

A:T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

Q:What is the lead time?

A:Usually sample lead time is 7 days after payment has been confirmed.