Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Product Details

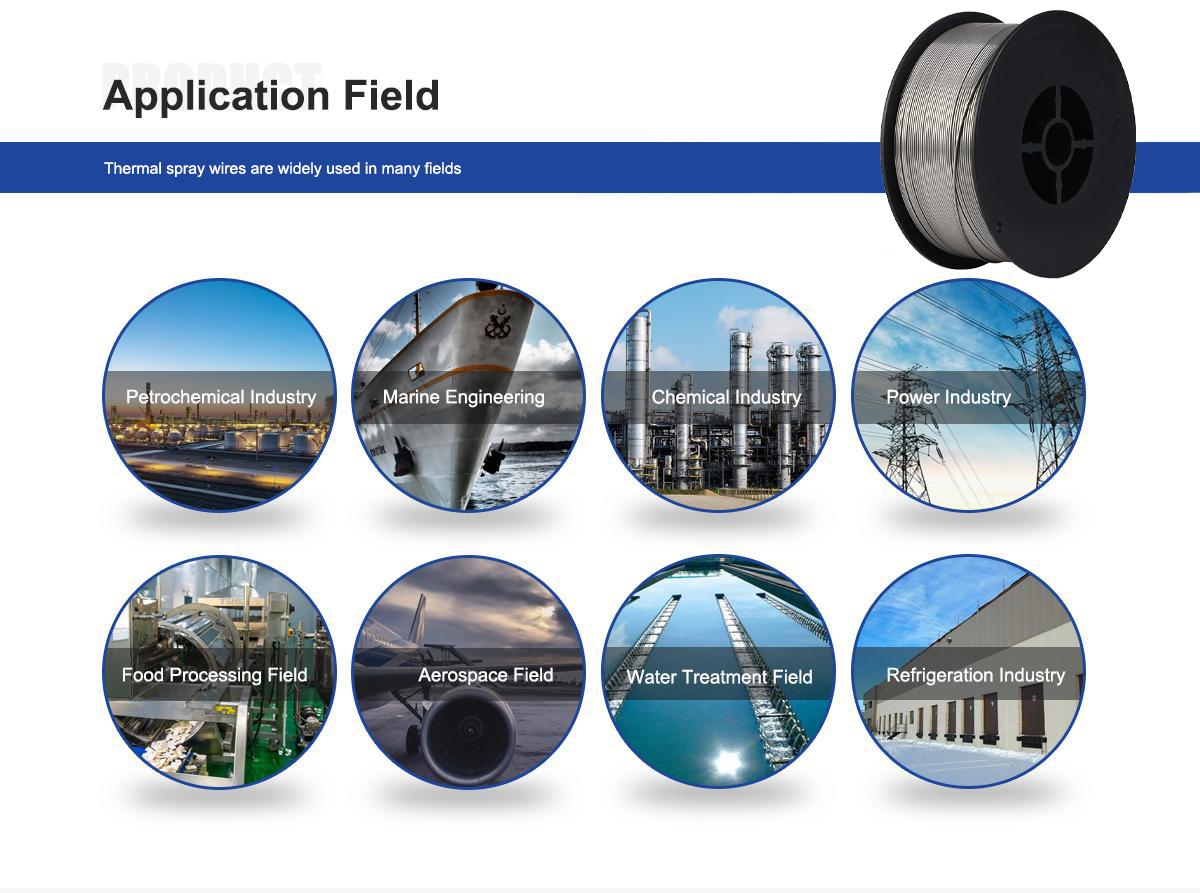

Thermal Spray Wire is widely used in arc and flange flame spray systems, offering exceptional resistance to corrosion and high temperatures. This makes it an ideal material for coatings that help resist heat and prevent scaling of conventional low-alloy steels. Thermal spray wire is also used as bond coats to improve the adhesion of top coatings, especially in applications like coatings on molds in the glass industry.

Thermal spray wire is available in various alloys, including Inconel 625 , 45CT, Ni95Al5, Monel 400, Monel K500, Hastelloy C276 , and Cr20Ni80. These alloys provide robust solutions for industrial applications, ensuring superior performance even in the harshest conditions.

| Element | Inconel 625 | Ni95Al5 | 45CT | Monel 400 | Monel K500 | HC-276 | Cr20Ni80 | S5420 | 0Cr25Al5 | Ni80A120 | Pure Zinc Wire | ZnA15 |

| C | ≤0.05 | ≤0.02 | ≤0.01 | ≤0.1 | ≤0.04 | ≤0.25 | ≤0.02 | ≤0.08 | 0.36-0.48 | ≤0.06 | ≤0.08 | - |

| Mn | ≤0.4 | ≤0.2 | ≤0.2 | 2.5-3.5 | ≤1.5 | ≤1.0 | ≤0.1 | ≤0.06 | ≤0.1 | ≤0.4 | ≤0.7 | ≤0.75 |

| P | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.02 | ≤0.01 | ≤0.01 | ≤0.04 | ≤0.05 | ≤0.025 | ≤0.02 |

| S | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.03 | ≤0.03 | ≤0.025 | - |

| Si | ≤0.15 | ≤0.2 | ≤0.2 | ≤0.15 | ≤0.5 | ≤0.08 | 0.75-1.6 | ≤1 | ≤1 | ≤0.6 | ≤0.5 | ≤0.12 |

| Sn | - | - | - | - | - | - | - | - | - | - | - | ≤0.001 |

| Pb | - | - | - | - | - | - | - | - | - | - | - | ≤0.005 |

| Cd | - | - | - | - | - | - | - | - | - | - | - | ≤0.005 |

| Cr | 21.5-23 | ≤0.2 | 42-46 | - | - | 14.5-16 | 20-23 | 12-14 | 23.26 | ≤0.0015 | - | - |

| Ni | Balance | Balance | Balance | 65-67 | Balance | 27-33 | - | - | - | ≤0.6 | ≤0.6 | Balance |

| Cu | - | - | - | Balance | Balance | - | - | - | - | - | - | ≤0.002 |

| Mo | 8.5-10 | - | - | - | - | 15-17 | - | - | - | - | - | ≤0.01 |

| Ti | ≤0.4 | 0.4-1 | 0.3-1.0 | 2.0-3.0 | 0.35-0.85 | - | - | - | - | - | - | - |

| Al | ≤0.4 | 4-5 | ≤0.5 | ≤0.5 | 2.3-3.15 | - | - | - | - | 4.5-6.5 | 19-20 | ≤0.001 |

| Fe | ≤1.0 | - | ≤0.5 | ≤1.0 | ≤1.0 | 4.0-7.0 | - | - | - | - | - | 14-16 |

| Nb | 3.15-4.15 | - | - | - | - | - | ≤1.0 | - | - | - | - | ≤0.02 |

| Co | - | - | - | - | - | - | - | - | - | - | - | ≤0.05 |

| V | - | - | - | - | - | - | - | ≤0.35 | - | - | - | - |

| W | - | - | - | - | - | 3.0-4.5 | - | - | - | - | - | - |

| Zinc | - | - | - | - | - | - | - | - | - | - | ≥99.95 | 84-86 |

| Impurities | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 | - | - | - | - | - | - |

High-Temperature Performance: Cr20Ni80 can withstand temperatures up to 1200°C (2192°F), making it ideal for high-temperature applications such as heating elements, resistors, and various industrial coatings.

Excellent Oxidation Resistance: The wire provides superior resistance to oxidation, ensuring long-term performance and durability in extreme environments like high-temperature processing and corrosive conditions.

Good Electrical Conductivity: The low electrical resistivity of Cr20Ni80 makes it a great choice for applications that require good electrical conductivity, such as heating elements and electrical components.

Enhanced Mechanical Strength: Cr20Ni80 boasts high tensile and yield strength, which contributes to its durability and reliability in demanding industrial applications.

High Nickel Content: With a minimum of 75% nickel, Cr20Ni80 offers excellent corrosion resistance and enhanced performance in aggressive and harsh environments.

Versatile Application: Cr20Ni80 is used in thermal spray coatings for various high-temperature industrial components such as heating elements, resistors, and electrical components.

Durable and Long-Lasting: The alloy’s high hardness and elongation properties allow it to withstand mechanical stress and wear, making it a durable and long-lasting material.

Vacuum Coating: Cr20Ni80 is used for thermal spray coatings in vacuum coating systems, enhancing the durability of the components exposed to high temperatures.

Valves and Vacuum Components: It is employed in making valves grids, inner components of vacuum valves, and various vacuum-sealed systems, where resistance to heat and corrosion is critical.

Electron Tubes: Cr20Ni80 is used in components inside electron tubes, providing excellent performance under high heat and electrical demands.

Electrical Components: The wire is widely used in electrical components, such as heating elements, resistors, and conductors, where high-temperature resistance and good electrical conductivity are required.

Battery Production: Cr20Ni80 is ideal for use in battery production, where durability and resistance to oxidation are vital for efficient performance.

Strong Base for Filters: The wire is used as a strong base material for industrial filters, where resistance to high temperatures and corrosion is essential.

Heating Elements: It is employed in the manufacturing of connections for heating elements, including heating spirals in spark plugs, ensuring reliable performance in high-temperature environments.

High-Temperature Resistance: Cr20Ni80 wire can withstand extreme temperatures, up to 1200°C (2192°F), which makes it ideal for use in high-heat applications like heating elements and resistors.

Superior Oxidation Resistance: The wire's excellent oxidation resistance ensures that it performs reliably in high-temperature, corrosive environments, making it suitable for use in various industrial applications.

Good Electrical Conductivity: With low resistivity, Cr20Ni80 is highly efficient in applications requiring electrical conductivity, such as heating elements and electrical components.

Enhanced Strength: The high mechanical strength of Cr20Ni80 wire allows it to endure harsh conditions, providing durability and longevity in demanding environments.

Durable and Long-Lasting: Thanks to its hardness and resistance to wear, Cr20Ni80 wire is highly durable, minimizing the need for replacements.

Versatile: Cr20Ni80 is compatible with various thermal spray processes, including arc and flame spraying, making it suitable for a wide range of applications.

Q: What is Cr20Ni80 nickel alloy spray wire used for?

A: It is used for thermal spray coatings in high-temperature applications, such as heating elements, resistors, and other industrial components.

Q: What industries use Cr20Ni80 spray wire?

A: Cr20Ni80 is commonly used in industries like electrical, aerospace, automotive, and manufacturing.

Q: What is the maximum temperature resistance of Cr20Ni80?

A: Cr20Ni80 can withstand temperatures up to 1200°C (2192°F).

Q: What are the main properties of Cr20Ni80?

A: Cr20Ni80 features excellent oxidation resistance, high tensile strength, and low electrical resistivity, making it ideal for high-temperature and electrical applications.

Q: What is the minimum nickel content in Cr20Ni80?

A: The minimum nickel content is 75%.

Q: What thermal spray techniques are compatible with Cr20Ni80?

A: Cr20Ni80 is compatible with various thermal spray techniques, including arc and flame spraying.

Q: How does Cr20Ni80 perform in harsh environments?

A: Cr20Ni80 provides strong resistance to oxidation and maintains reliable performance even in aggressive environments, ensuring durability in demanding applications.