Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Product Details

The GH5605 (Haynes® 25 or L605) superalloy strip is a cobalt-based high-performance material known for its exceptional mechanical properties and superior resistance to oxidation, corrosion, and high-temperature environments. This versatile alloy is ideal for demanding applications in industries where high strength, durability, and stability under extreme heat are critical.

With its ability to retain strength at temperatures up to 1800°F (980°C) and excellent resistance to both oxidizing and reducing environments, GH5605 is the go-to material for components exposed to harsh operating conditions. This makes it perfect for aerospace, power generation, petrochemical, and marine industries, where material reliability is paramount.

Item | Nimonic80A | Nimonic 90 | GH1140 | GH3625 | GH3536 | GH4169 | |

C | ≤0.08 | ≤0.1 | ≤0.13 | 0.06-0.12 | ≤0.1 | 0.05-0.15 | ≤0.08 |

Mn | ≤2 | ≤1 | ≤1 | ≤0.7 | 3.14-4.15 | -- | ≤0.35 |

Fe | rest | ≤3 | ≤1.5 | rest | ≤0.5 | -- | rest |

P | ≤0.04 | ≤0.02 | -- | ≤0.025 | -- | -- | -- |

S | ≤0.03 | ≤0.015 | ≤0.015 | ≤0.015 | -- | -- | ≤0.01 |

Si | ≤1 | ≤1 | ≤1 | ≤0.8 | -- | -- | ≤0.35 |

Cu | -- | -- | ≤0.2 | -- | -- | -- | ≤0.3 |

Ni | 24-27 | rest | -- | 35-40 | rest | rest | 50-55 |

Co | -- | ≤2 | 15-21 | -- | ≤1.00 | 0.5-2.5 | ≤1.00 |

Al | ≤0.35 | 1-1.8 | 1-2 | 0.2-0.6 | ≤0.4 | ≤0.5 | 0.2-0.8 |

Ti | 1.9-2.35 | 1.8-2.7 | 2-3 | 0.7-1.2 | ≤0.4 | ≤0.15 | 0.7-1.15 |

Cr | 13.5-16 | 18-21 | 18-21 | 20-23 | 20-23 | 20.5-23 | 17-21 |

Nb | -- | -- | -- | -- | -- | -- | 4.75-5.5 |

Mo | 1-1.5 | -- | -- | 2-2.5 | 8-10 | 8-10 | 2.8-3.3 |

B | 0.001-0.1 | ≤0.008 | ≤0.02 | -- | -- | -- | -- |

V | 0.1-0.5 | -- | -- | -- | -- | -- | -- |

W | -- | -- | -- | 1.4-1.8 | -- | 0.2-1 | -- |

Zr | -- | ≤0.15 | ≤0.15 | -- | -- | -- | -- |

Pb | -- | -- | ≤0.002 | -- | -- | -- | -- |

Ce | -- | -- | -- | ≤0.05 | -- | -- | -- |

Size Range | |

Wire | 0.5-7.5mm |

Rod/Bar | 8.0-200mm |

Strip | (0.50-2.5)*(5-180)mm |

Tube | custom made |

| Plate | custom made |

High-Temperature Strength: Retains mechanical properties at temperatures up to 1800°F (980°C).

Corrosion Resistance: Excellent oxidation and corrosion resistance, especially in reducing atmospheres and seawater.

Wear and Galling Resistance: Demonstrates exceptional resistance to wear and galling, ideal for components subjected to friction in extreme temperatures.

Creep and Fatigue Resistance: Maintains structural integrity under thermal cycling and mechanical stress.

Fabricability: Can be welded, machined, and formed into complex shapes without compromising its mechanical properties.

Low Electrical Resistivity: Useful in applications where electrical performance is a concern.

Aerospace Industry:

Turbine Components: Used in high-temperature sections such as turbine blades, combustor liners, and afterburners in aircraft engines and gas turbines.

Exhaust Systems: Durable in exhaust components that are subjected to extreme temperatures and corrosive gases.

Power Generation:

Gas and Steam Turbine Parts: Ideal for turbine blades, seals, and nozzles exposed to high heat and stress.

Heat Shields and Combustion Chambers: Employed in power plants to withstand thermal stress and oxidation in heat shields and combustion chambers.

Chemical Processing Industry:

Heat Exchangers and Reactors: Suitable for high-temperature chemical processing equipment due to its resistance to corrosive media and oxidation.

Furnace Linings: Used in furnace linings where resistance to thermal cycling and high-temperature oxidation is required.

Automotive Industry:

Turbochargers and Exhaust Components: Used for high-performance engines in turbochargers and exhaust valves, ensuring heat and corrosion resistance.

Marine Applications:

Marine Engine Components: Essential for marine engine parts such as exhaust manifolds, heat exchangers, and turbochargers, providing resistance to saltwater corrosion and high heat.

Nuclear Industry:

Control Rod Assemblies: Utilized in nuclear reactors for critical components such as control rods, where high strength and corrosion resistance in radiation environments are necessary.

Pressure Vessels: Suitable for pressure vessels exposed to both high temperatures and radiation.

Medical Industry:

Surgical Instruments & Implants: L605 is used in medical devices, particularly in surgical instruments and orthopedic implants, providing strength and biocompatibility.

The manufacturing of GH5605 involves precision melting and alloying techniques to achieve the desired mechanical properties. Once the alloy is produced, it undergoes processes such as hot rolling, cold rolling, and heat treatment to enhance its strength, ductility, and resistance to oxidation. The strips can be further fabricated using welding, machining, and forming processes to meet specific application requirements.

Exceptional High-Temperature Performance: Retains strength and structural integrity up to 1800°F (980°C).

Long Service Life: Its combination of corrosion and oxidation resistance ensures extended service life, especially in aggressive and harsh environments.

Versatility in Applications: Suitable for aerospace, automotive, marine, power generation, and chemical processing industries.

Excellent Fabricability: Easily fabricated into complex shapes without compromising its mechanical properties.

High Resistance to Fatigue and Creep: Ideal for components that undergo mechanical stress and thermal cycling over time.

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got ISO9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, Precision Alloy , FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

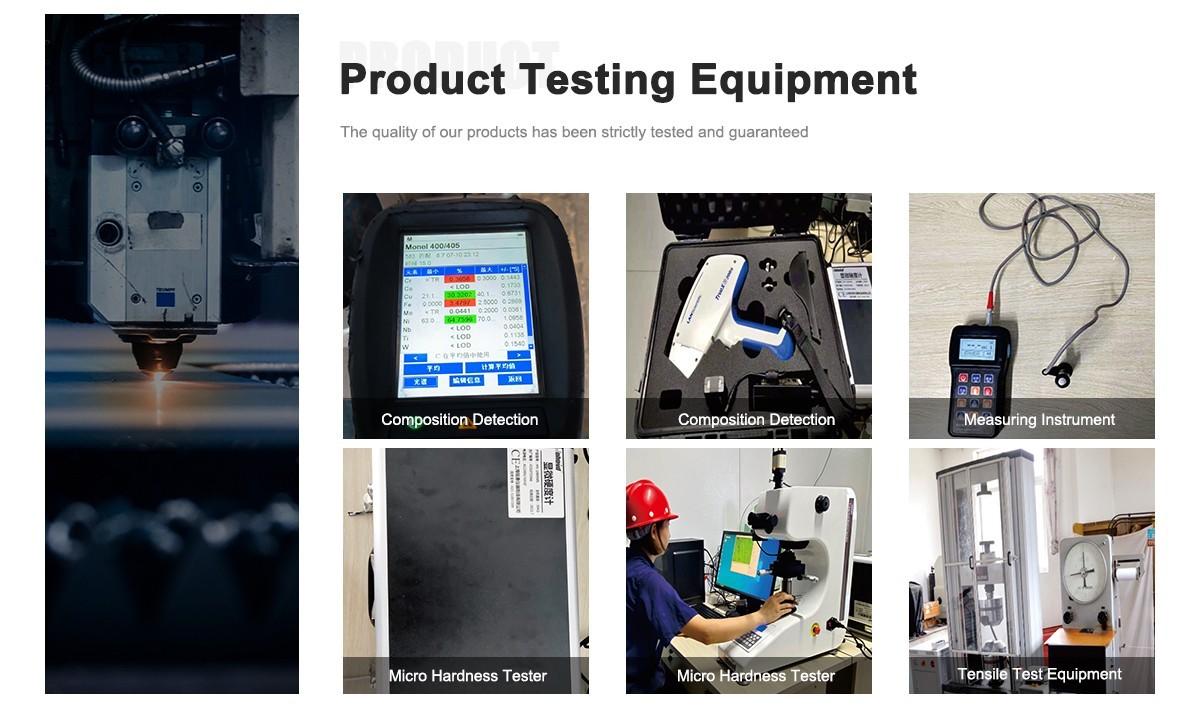

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

1. What is GH5605 used for?

GH5605 (L605) is primarily used in high-performance applications that involve exposure to high temperatures, mechanical stress, and corrosive environments. Common industries include aerospace, power generation, automotive, marine, and chemical processing.

2. What are the key properties of GH5605?

GH5605 offers high-temperature strength, oxidation and corrosion resistance, wear and galling resistance, and excellent creep and fatigue resistance. It retains its mechanical properties at temperatures up to 1800°F (980°C).

3. What industries benefit from GH5605?

Industries such as aerospace, power generation, petrochemical, marine, and automotive rely on GH5605 for components requiring high-temperature strength and corrosion resistance.

4. What is the maximum temperature GH5605 can withstand?

GH5605 can withstand temperatures up to 1800°F (980°C) without compromising its mechanical properties.

5. How is GH5605 fabricated?

GH5605 can be welded, machined, and formed into complex shapes using standard fabrication techniques. It is suitable for both hot and cold working processes.

6. Can GH5605 be used in medical applications?

Yes, GH5605 is used in medical devices, particularly for surgical instruments and implants, due to its high strength, corrosion resistance, and biocompatibility.

7. What is the chemical composition of GH5605?

GH5605 consists mainly of cobalt, chromium, tungsten, and nickel, along with trace amounts of iron. This composition provides excellent strength, oxidation, and corrosion resistance.