Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Product Details

The HC-276 nickel alloy spray wire is engineered for thermal spray applications, offering exceptional protection against corrosive environments. This alloy wire is designed to provide superior resistance to harsh chemicals, including acids, chlorides, and seawater, ensuring extended service life and enhanced durability in aggressive industrial environments. It is commonly used for coating critical components such as pumps, valves, and heat exchangers, making it an essential material in various industries.

| Element | Inconel 625 | Ni95Al5 | 45CT | Monel 400 | Monel K500 | HC-276 | Cr20Ni80 | S5420 | 0Cr25Al5 | Ni80A120 | Pure Zinc Wire | ZnA15 |

| C | ≤0.05 | ≤0.02 | ≤0.01 | ≤0.1 | ≤0.04 | ≤0.25 | ≤0.02 | ≤0.08 | 0.36-0.48 | ≤0.06 | ≤0.08 | - |

| Mn | ≤0.4 | ≤0.2 | ≤0.2 | 2.5-3.5 | ≤1.5 | ≤1.0 | ≤0.1 | ≤0.06 | ≤0.1 | ≤0.4 | ≤0.7 | ≤0.75 |

| P | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.02 | ≤0.01 | ≤0.01 | ≤0.04 | ≤0.05 | ≤0.025 | ≤0.02 |

| S | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.03 | ≤0.03 | ≤0.025 | - |

| Si | ≤0.15 | ≤0.2 | ≤0.2 | ≤0.15 | ≤0.5 | ≤0.08 | 0.75-1.6 | ≤1 | ≤1 | ≤0.6 | ≤0.5 | ≤0.12 |

| Sn | - | - | - | - | - | - | - | - | - | - | - | ≤0.001 |

| Pb | - | - | - | - | - | - | - | - | - | - | - | ≤0.005 |

| Cd | - | - | - | - | - | - | - | - | - | - | - | ≤0.005 |

| Cr | 21.5-23 | ≤0.2 | 42-46 | - | - | 14.5-16 | 20-23 | 12-14 | 23.26 | ≤0.0015 | - | - |

| Ni | Balance | Balance | Balance | 65-67 | Balance | 27-33 | - | - | - | ≤0.6 | ≤0.6 | Balance |

| Cu | - | - | - | Balance | Balance | - | - | - | - | - | - | ≤0.002 |

| Mo | 8.5-10 | - | - | - | - | 15-17 | - | - | - | - | - | ≤0.01 |

| Ti | ≤0.4 | 0.4-1 | 0.3-1.0 | 2.0-3.0 | 0.35-0.85 | - | - | - | - | - | - | - |

| Al | ≤0.4 | 4-5 | ≤0.5 | ≤0.5 | 2.3-3.15 | - | - | - | - | 4.5-6.5 | 19-20 | ≤0.001 |

| Fe | ≤1.0 | - | ≤0.5 | ≤1.0 | ≤1.0 | 4.0-7.0 | - | - | - | - | - | 14-16 |

| Nb | 3.15-4.15 | - | - | - | - | - | ≤1.0 | - | - | - | - | ≤0.02 |

| Co | - | - | - | - | - | - | - | - | - | - | - | ≤0.05 |

| V | - | - | - | - | - | - | - | ≤0.35 | - | - | - | - |

| W | - | - | - | - | - | 3.0-4.5 | - | - | - | - | - | - |

| Zinc | - | - | - | - | - | - | - | - | - | - | ≥99.95 | 84-86 |

| Impurities | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 | - | - | - | - | - | - |

Superior Corrosion Resistance: This wire provides unmatched protection against a wide variety of corrosive environments, including acids, chlorides, and seawater, making it perfect for use in challenging conditions.

High-Temperature Stability: HC-276 can withstand temperatures up to 1250°C (2282°F), ensuring reliable performance in high-heat industrial applications.

Mechanical Strength: With excellent tensile strength and yield strength, HC-276 guarantees durability and long-term reliability even under mechanical stress.

Ductility: The wire offers outstanding elongation properties, enabling it to withstand mechanical stress without cracking or breaking.

Low Electrical Resistivity: HC-276 maintains consistent performance in environments where electrical conductivity is crucial, such as in electronic and electrical applications.

Ease of Application: Compatible with a range of thermal spray techniques, ensuring uniform coating results for a variety of industrial applications.

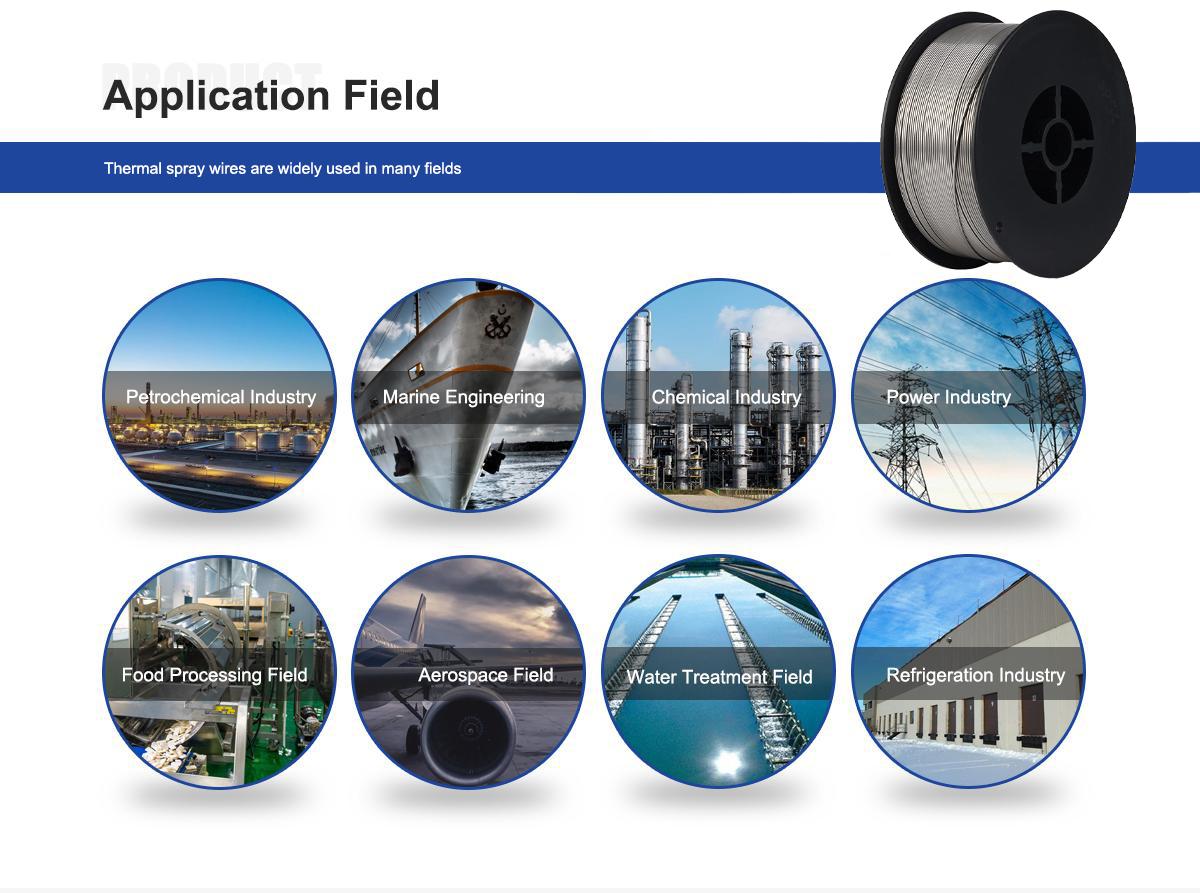

Applications of HC-276 Nickel Alloy Spray Wire

HC-276 spray wire is widely used in industries where materials must endure severe environmental stress. Common applications include:

Thermal Spray Coatings: Protects critical components like pumps, valves, and heat exchangers in industries that face aggressive chemicals or extreme temperatures.

Marine Applications: The wire’s high resistance to corrosion in seawater environments makes it ideal for marine-related equipment.

Chemical Processing: Provides long-lasting protection against chemical attacks in chemical processing plants, ensuring equipment longevity.

Power Generation: Used in power generation systems for thermal spray coatings to protect turbines, reactors, and other vital components.

Oil & Gas: HC-276 wire is essential in the oil and gas industry, where high resistance to corrosive materials is critical.

Electronics Manufacturing: Its low electrical resistivity and mechanical strength make it useful in applications like electronic components, battery production, and vacuum valves.

Specialized Applications: Also used for vacuum coating, electronic tube components, and heating elements in devices like spark plugs.

In addition to HC-276, we offer a wide range of thermal spray wire options, including:

Inconel 625

45CT

Ni95Al5

Monel 400

Monel K500

Hastelloy C276

Cr20Ni80

These wires are engineered for high mechanical properties, exceptional corrosion resistance, and high-temperature applications, ensuring a perfect match for your specific needs.

Outstanding Corrosion Resistance: With a nickel and molybdenum-rich composition, HC-276 excels in protecting equipment from acids, chlorides, and other aggressive chemicals.

High-Temperature Performance: Withstanding up to 1250°C, this wire is ideal for industries that require materials to perform under extreme heat.

Mechanical Durability: High tensile and yield strengths ensure that the wire retains its integrity even under mechanical stress.

Versatility: Its compatibility with various thermal spray techniques such as arc spraying and flame spraying makes it an adaptable choice for a range of industries.

Reliable Performance in Harsh Environments: Perfect for industries like marine, chemical processing, and oil & gas.

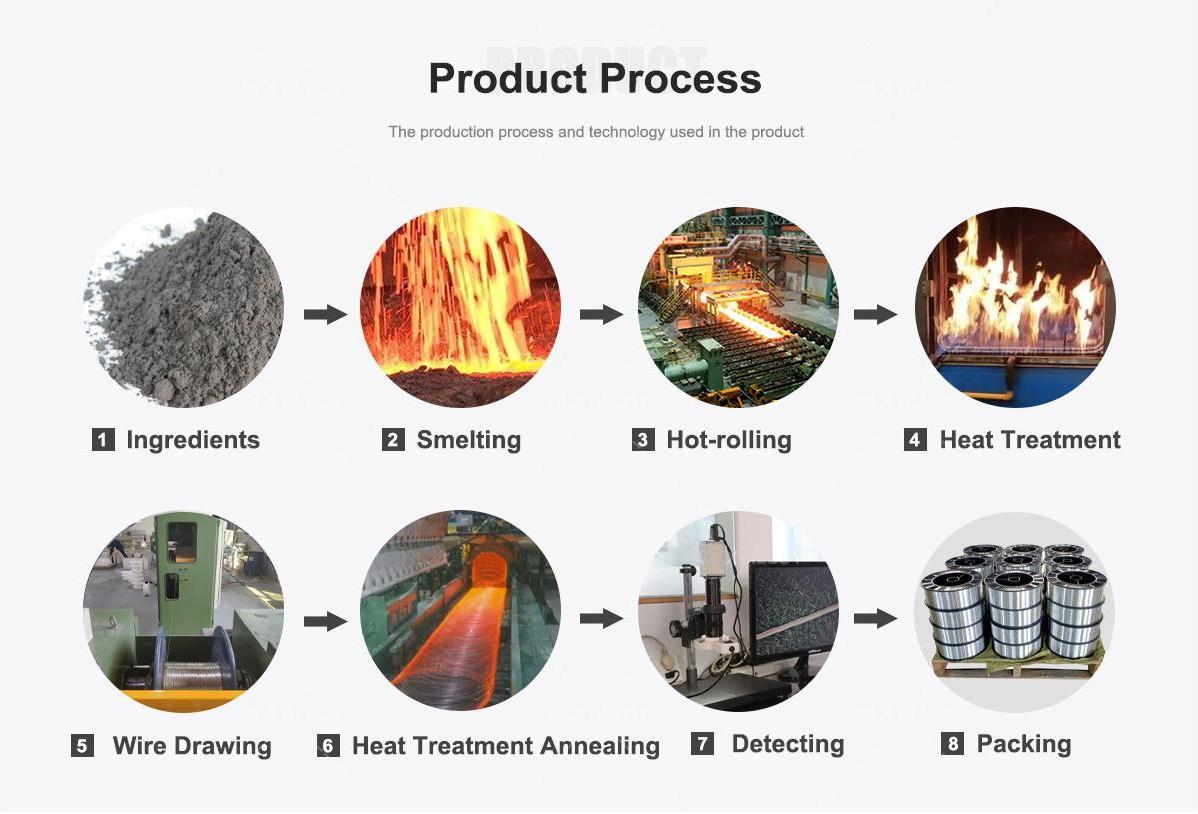

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got ISO9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, Precision Alloy , FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

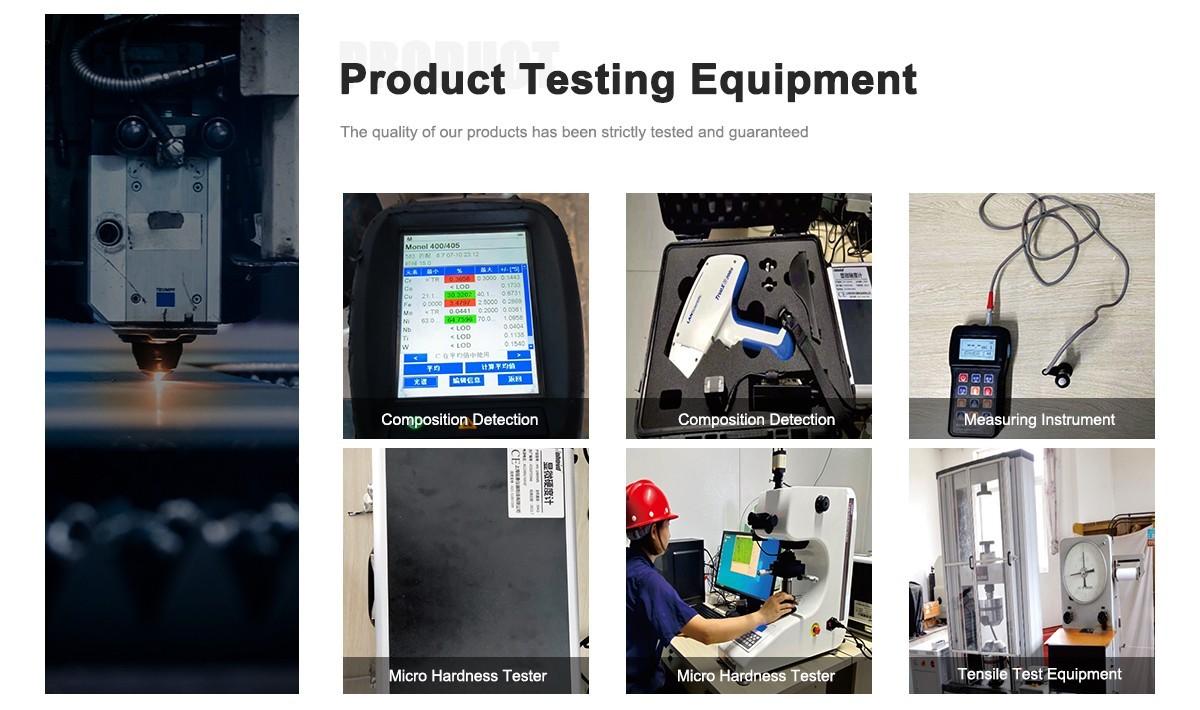

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

FAQ – HC-276 Nickel Alloy Spray Wire

What is HC-276 nickel alloy spray wire used for?

HC-276 is primarily used for thermal spray coatings to protect equipment like pumps, valves, and heat exchangers in harsh chemical and high-temperature environments.

What industries use HC-276 spray wire?

It is commonly used in industries such as chemical processing, marine, power generation, and oil & gas.

What is the maximum temperature resistance of HC-276?

HC-276 can withstand temperatures up to 1250°C (2282°F), making it suitable for high-heat industrial applications.

What makes HC-276 highly resistant to corrosion?

HC-276 contains high levels of nickel and molybdenum, which provide excellent resistance to acids, chlorides, and other aggressive chemicals, including seawater.

What is the minimum nickel content in HC-276 spray wire?

The nickel content in HC-276 is at least 57%.

Can HC-276 be used in seawater environments?

Yes, HC-276 is highly resistant to seawater corrosion, making it ideal for marine applications.

What thermal spray techniques can be used with HC-276?

HC-276 is compatible with various thermal spray processes, including arc spraying and flame spraying, ensuring consistent and efficient coating results.