Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Product Details

Monel 500 wire is a high-performance nickel-copper alloy designed to deliver superior strength and corrosion resistance. It is widely used in thermal spray applications to provide protective coatings for components exposed to harsh environmental conditions, such as marine environments, chemical processing, and high-temperature applications. Its exceptional performance in resistance to corrosion, oxidation, and mechanical stress makes it a versatile choice for a wide range of industrial applications, including vacuum coating and manufacturing electronic components.

Monel 500 wire ensures that coated surfaces maintain durability and high performance even under extreme conditions, making it an essential material for industries that require long-lasting, reliable protection. Whether you're involved in aerospace, marine engineering, or battery production, Monel 500 is an ideal choice for creating high-quality, protective coatings.

| Element | Inconel 625 | Ni95Al5 | 45CT | Monel 400 | Monel K500 | HC-276 | Cr20Ni80 | S5420 | 0Cr25Al5 | Ni80A120 | Pure Zinc Wire | ZnA15 |

| C | ≤0.05 | ≤0.02 | ≤0.01 | ≤0.1 | ≤0.04 | ≤0.25 | ≤0.02 | ≤0.08 | 0.36-0.48 | ≤0.06 | ≤0.08 | - |

| Mn | ≤0.4 | ≤0.2 | ≤0.2 | 2.5-3.5 | ≤1.5 | ≤1.0 | ≤0.1 | ≤0.06 | ≤0.1 | ≤0.4 | ≤0.7 | ≤0.75 |

| P | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.02 | ≤0.01 | ≤0.01 | ≤0.04 | ≤0.05 | ≤0.025 | ≤0.02 |

| S | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.03 | ≤0.03 | ≤0.025 | - |

| Si | ≤0.15 | ≤0.2 | ≤0.2 | ≤0.15 | ≤0.5 | ≤0.08 | 0.75-1.6 | ≤1 | ≤1 | ≤0.6 | ≤0.5 | ≤0.12 |

| Sn | - | - | - | - | - | - | - | - | - | - | - | ≤0.001 |

| Pb | - | - | - | - | - | - | - | - | - | - | - | ≤0.005 |

| Cd | - | - | - | - | - | - | - | - | - | - | - | ≤0.005 |

| Cr | 21.5-23 | ≤0.2 | 42-46 | - | - | 14.5-16 | 20-23 | 12-14 | 23.26 | ≤0.0015 | - | - |

| Ni | Balance | Balance | Balance | 65-67 | Balance | 27-33 | - | - | - | ≤0.6 | ≤0.6 | Balance |

| Cu | - | - | - | Balance | Balance | - | - | - | - | - | - | ≤0.002 |

| Mo | 8.5-10 | - | - | - | - | 15-17 | - | - | - | - | - | ≤0.01 |

| Ti | ≤0.4 | 0.4-1 | 0.3-1.0 | 2.0-3.0 | 0.35-0.85 | - | - | - | - | - | - | - |

| Al | ≤0.4 | 4-5 | ≤0.5 | ≤0.5 | 2.3-3.15 | - | - | - | - | 4.5-6.5 | 19-20 | ≤0.001 |

| Fe | ≤1.0 | - | ≤0.5 | ≤1.0 | ≤1.0 | 4.0-7.0 | - | - | - | - | - | 14-16 |

| Nb | 3.15-4.15 | - | - | - | - | - | ≤1.0 | - | - | - | - | ≤0.02 |

| Co | - | - | - | - | - | - | - | - | - | - | - | ≤0.05 |

| V | - | - | - | - | - | - | - | ≤0.35 | - | - | - | - |

| W | - | - | - | - | - | 3.0-4.5 | - | - | - | - | - | - |

| Zinc | - | - | - | - | - | - | - | - | - | - | ≥99.95 | 84-86 |

| Impurities | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 | - | - | - | - | - | - |

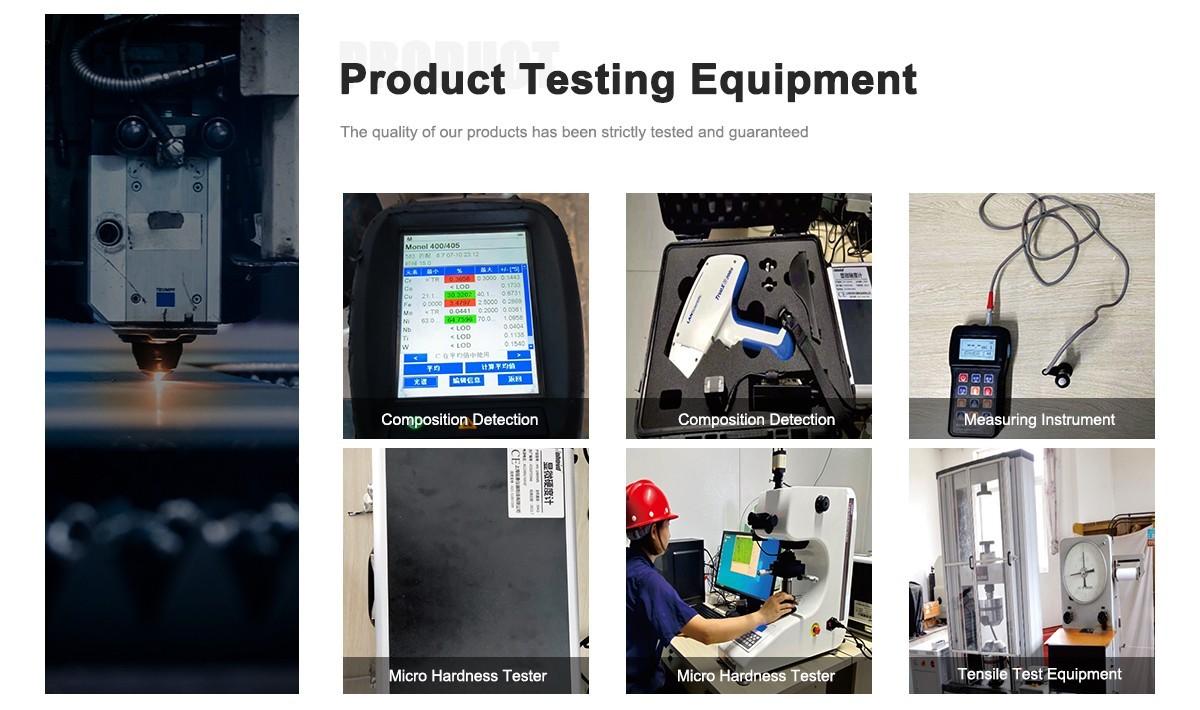

Exceptional Corrosion Resistance: Monel 500 wire is highly resistant to corrosion, particularly in seawater and acidic or alkaline environments, ensuring extended service life and minimal maintenance.

High Mechanical Strength: The wire offers impressive tensile strength, allowing it to withstand heavy mechanical stress and high-pressure applications.

Oxidation Resistance: Monel 500 performs excellently at elevated temperatures, retaining its strength and functionality even in oxidizing environments.

Superb Fabricability: Easy to fabricate into various shapes, Monel 500 wire can be used in diverse industrial processes, enhancing versatility across applications.

Dimensional Stability: Maintains its shape under stress, which is critical for high-performance applications that require high structural integrity.

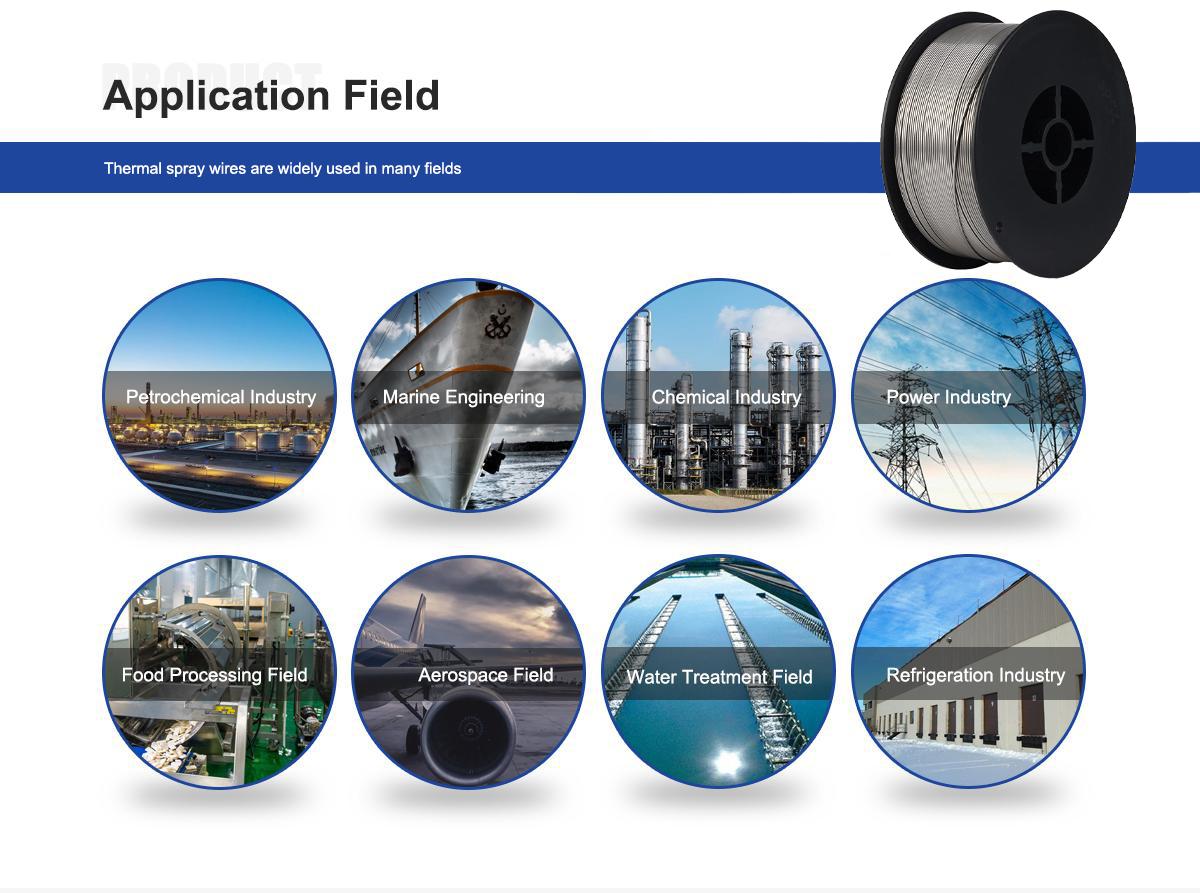

Monel 500 wire is a versatile material used in various industries requiring high strength and corrosion resistance. Here are some of its most common applications:

Marine Engineering: Perfect for use in shipbuilding and offshore platforms where it resists seawater corrosion.

Aerospace Components: Ideal for parts subjected to extreme conditions, such as aircraft engine components and exhaust systems.

Chemical Processing Equipment: Used in reactors, distillation columns, and heat exchangers where resistance to harsh chemicals is essential.

Oil and Gas Industry: Commonly used for making oil well equipment, tubing, and downhole tools due to its ability to withstand high pressures and temperatures.

Electronic Components: Excellent for making reliable electrical components, especially those exposed to harsh conditions or requiring corrosion resistance.

Vacuum Coating: Used in vacuum coating systems to enhance the durability and adhesion of coatings.

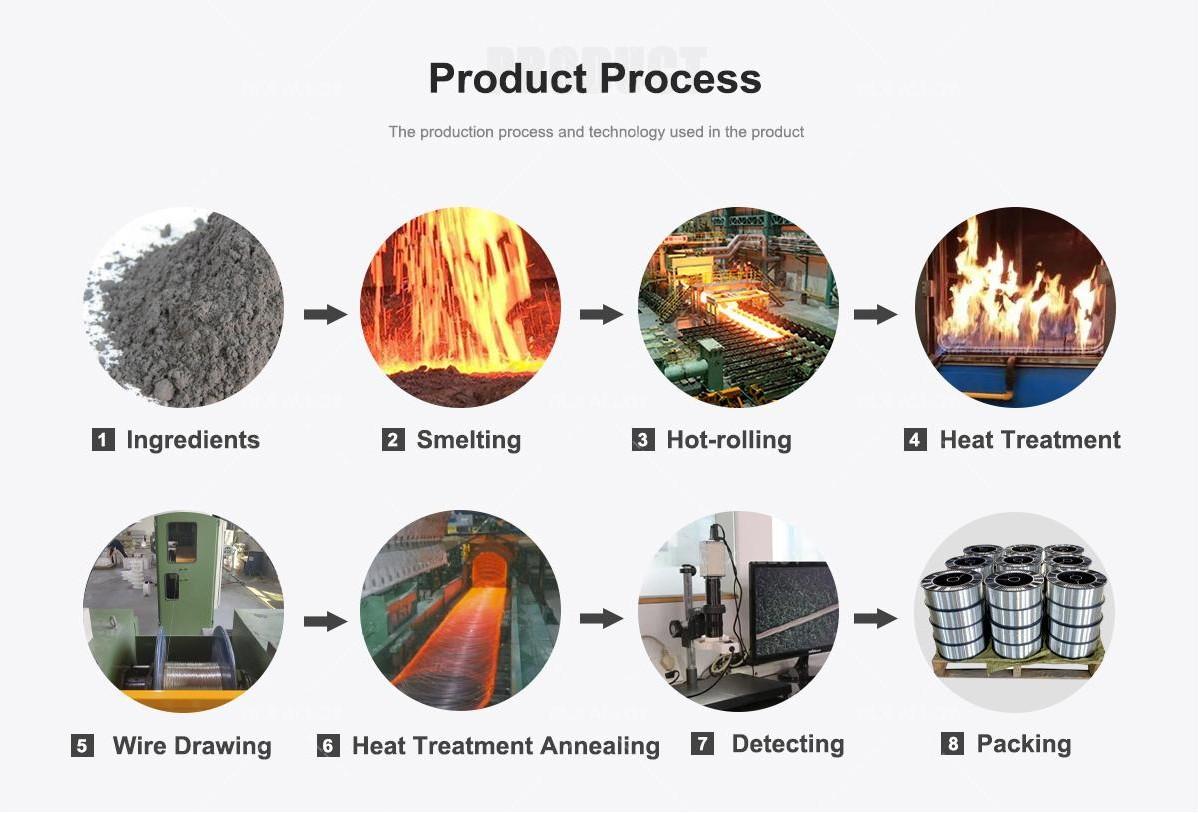

The Monel 500 wire is typically processed using thermal spray techniques such as arc spraying or flame spraying. These processes involve melting the wire and projecting it onto the surface of a substrate to form a durable, corrosion-resistant coating. The wire's excellent flow properties and high melting point ensure smooth coating applications that are both uniform and effective in providing protection against oxidation and corrosion.

Outstanding Durability: The combination of high mechanical strength and corrosion resistance ensures that Monel 500 wire provides long-lasting protection in even the most challenging environments.

High Temperature Performance: Monel 500 maintains its structural integrity in high-temperature applications, making it suitable for industries where extreme heat is a factor.

Versatility Across Industries: From marine engineering to electronics and aerospace, Monel 500 wire can be applied across a wide range of sectors, enhancing performance and protection in each.

Ease of Fabrication: The wire can be easily fabricated into different shapes, providing flexibility for manufacturers and engineers in customizing components for specific needs.

Cost-Effective Maintenance: Its resistance to corrosion and wear reduces the need for frequent maintenance or replacement, making it a cost-effective option in long-term industrial use.

Q1: What is Monel 500 wire made of?

A1: Monel 500 wire is a nickel-copper alloy, known for its excellent strength and corrosion resistance properties.

Q2: Where is Monel 500 wire commonly used?

A2: It is used across various industries, including marine, aerospace, chemical processing, and oil & gas, due to its resistance to harsh environments.

Q3: Can Monel 500 wire withstand high temperatures?

A3: Yes, Monel 500 wire can perform well in high-temperature environments, making it ideal for applications involving heat exposure.

Q4: How does Monel 500 wire compare to other alloys in corrosion resistance?

A4: Monel 500 wire offers superior corrosion resistance compared to many other alloys, particularly in marine and acidic environments.

Q5: Is Monel 500 wire easy to fabricate?

A5: Yes, Monel 500 wire is highly adaptable and can be fabricated into different shapes to meet specific industrial requirements.

Q6: How should Monel 500 wire be stored?

A6: Monel 500 wire should be stored in a dry and cool environment to maintain its quality and avoid corrosion.