Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Product Details

Thermal spray wire is widely used in arc and flange flame spray systems, offering exceptional resistance to corrosion and high temperatures. This makes it an ideal material for coatings that help to resist heat and prevent scaling of conventional low-alloy steels. Thermal spray wire is also used as bond coats to improve the adhesion of top coatings, especially in applications like coatings on molds in the glass industry.

Thermal spray wire comes in various alloys, including Inconel 625, 45CT, Ni95Al5, Monel 400, Monel K500, Hastelloy C276 , and Cr20Ni80. These materials provide robust solutions for industrial applications, ensuring superior performance even in the harshest conditions.

| Element | Inconel 625 | Ni95Al5 | 45CT | Monel 400 | Monel K500 | HC-276 | Cr20Ni80 | S5420 | 0Cr25Al5 | Ni80A120 | Pure Zinc Wire | ZnA15 |

| C | ≤0.05 | ≤0.02 | ≤0.01 | ≤0.1 | ≤0.04 | ≤0.25 | ≤0.02 | ≤0.08 | 0.36-0.48 | ≤0.06 | ≤0.08 | - |

| Mn | ≤0.4 | ≤0.2 | ≤0.2 | 2.5-3.5 | ≤1.5 | ≤1.0 | ≤0.1 | ≤0.06 | ≤0.1 | ≤0.4 | ≤0.7 | ≤0.75 |

| P | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.02 | ≤0.01 | ≤0.01 | ≤0.04 | ≤0.05 | ≤0.025 | ≤0.02 |

| S | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.03 | ≤0.03 | ≤0.025 | - |

| Si | ≤0.15 | ≤0.2 | ≤0.2 | ≤0.15 | ≤0.5 | ≤0.08 | 0.75-1.6 | ≤1 | ≤1 | ≤0.6 | ≤0.5 | ≤0.12 |

| Sn | - | - | - | - | - | - | - | - | - | - | - | ≤0.001 |

| Pb | - | - | - | - | - | - | - | - | - | - | - | ≤0.005 |

| Cd | - | - | - | - | - | - | - | - | - | - | - | ≤0.005 |

| Cr | 21.5-23 | ≤0.2 | 42-46 | - | - | 14.5-16 | 20-23 | 12-14 | 23.26 | ≤0.0015 | - | - |

| Ni | Balance | Balance | Balance | 65-67 | Balance | 27-33 | - | - | - | ≤0.6 | ≤0.6 | Balance |

| Cu | - | - | - | Balance | Balance | - | - | - | - | - | - | ≤0.002 |

| Mo | 8.5-10 | - | - | - | - | 15-17 | - | - | - | - | - | ≤0.01 |

| Ti | ≤0.4 | 0.4-1 | 0.3-1.0 | 2.0-3.0 | 0.35-0.85 | - | - | - | - | - | - | - |

| Al | ≤0.4 | 4-5 | ≤0.5 | ≤0.5 | 2.3-3.15 | - | - | - | - | 4.5-6.5 | 19-20 | ≤0.001 |

| Fe | ≤1.0 | - | ≤0.5 | ≤1.0 | ≤1.0 | 4.0-7.0 | - | - | - | - | - | 14-16 |

| Nb | 3.15-4.15 | - | - | - | - | - | ≤1.0 | - | - | - | - | ≤0.02 |

| Co | - | - | - | - | - | - | - | - | - | - | - | ≤0.05 |

| V | - | - | - | - | - | - | - | ≤0.35 | - | - | - | - |

| W | - | - | - | - | - | 3.0-4.5 | - | - | - | - | - | - |

| Zinc | - | - | - | - | - | - | - | - | - | - | ≥99.95 | 84-86 |

| Impurities | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 | - | - | - | - | - | - |

High mechanical properties: Thermal spray wires offer excellent strength and durability, ensuring longevity even under demanding conditions.

High corrosion resistance: These wires can withstand corrosive environments, which is essential for industries that deal with harsh chemicals and extreme temperatures.

High temperature coefficient of electrical resistance: Thermal spray wire offers superior thermal stability, maintaining its properties even in high-temperature applications.

Thermal spray wire is used across a wide range of industries and applications due to its versatility and high performance. Some common applications include:

For vacuum coating: Thermal spray wire is essential for vacuum coating processes, offering durability and strength to coated components.

Valve components: It is used in the manufacturing of valve grids and inner components of vacuum valves, providing enhanced wear resistance and longevity.

Electron tubes: Thermal spray wire is used in components inside electron tubes, where high mechanical strength and corrosion resistance are crucial.

Lead and supporting wires: These wires are also used for making lead and supporting wires for various electrical and mechanical applications.

Electronic components: Commonly used in the production of electronic components, where high conductivity and reliability are required.

Battery production: Thermal spray wire is integral in the manufacturing of batteries, ensuring that components perform efficiently under high-stress conditions.

Strong base of filters: Provides strong bases for filters used in various filtration systems, offering exceptional durability.

Manufacturing heating elements: The wire is used in heating elements and spark-plug heating spirals, crucial for high-temperature electrical applications.

45CT Wire offers numerous advantages, making it an ideal choice for demanding industrial applications. Some of the key benefits include:

High strength: 45CT wire provides excellent tensile strength and durability, suitable for use in applications that require tough, high-performance materials.

Good hardness: Known for its superior hardness, 45CT wire enhances wear resistance, which is crucial in parts exposed to friction and abrasion.

Versatile applications: It can be used in a wide range of industries, including automotive, machinery, and structural components, making it an adaptable material for different production needs.

Excellent machinability: The wire is easy to cut, shape, and form, making it a practical and efficient material for manufacturing.

Cost-effective: Offering a balance of performance and affordability, 45CT wire is an economical choice for industries looking for durability without breaking the bank.

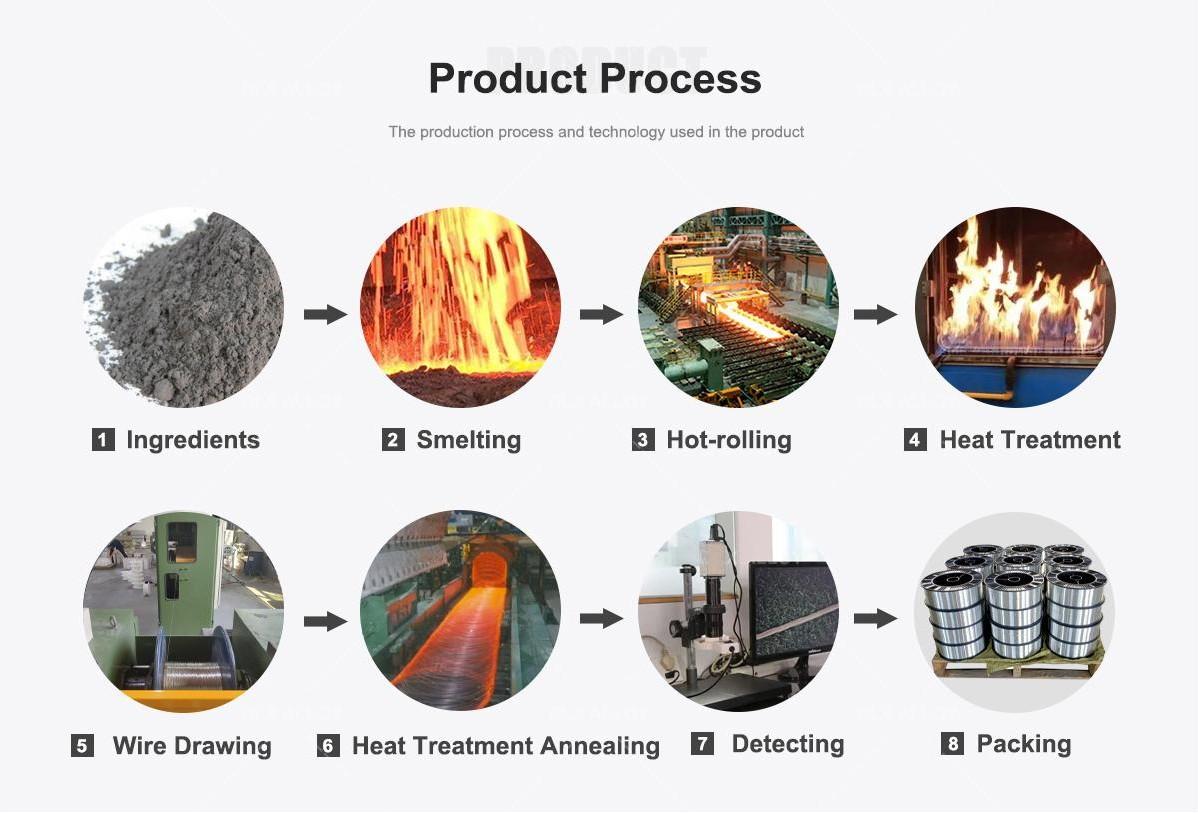

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got ISO9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, Precision Alloy , FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

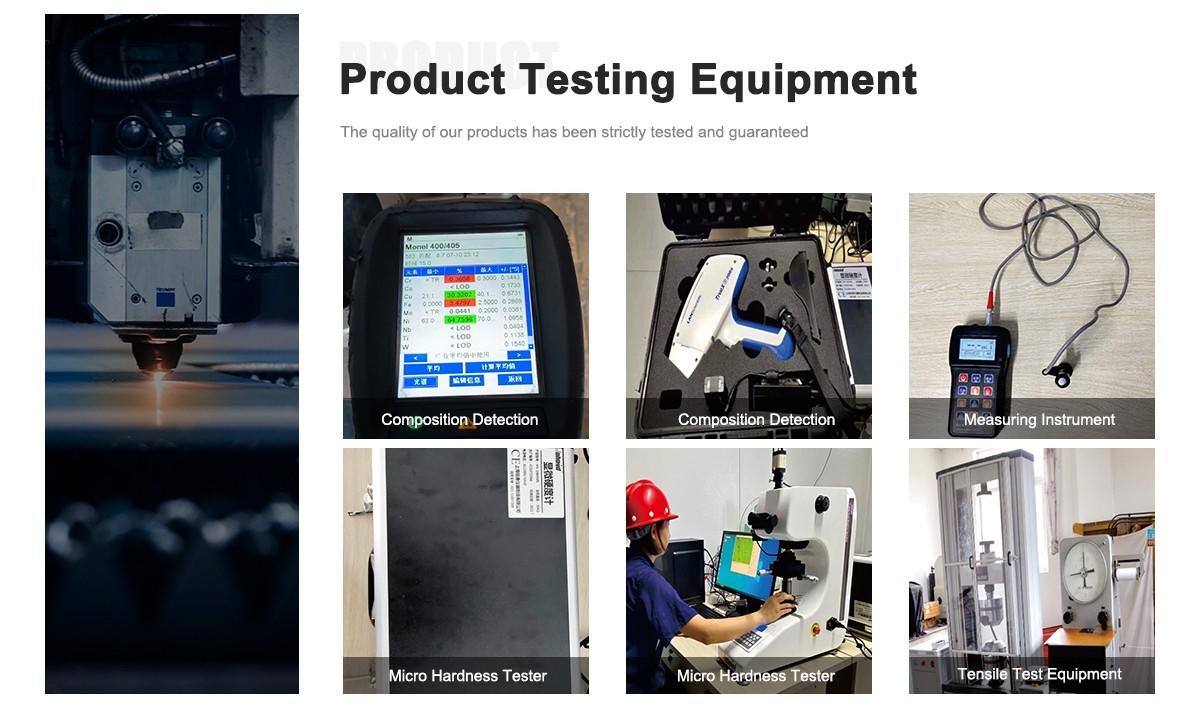

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Q: What is 45CT wire?

A: 45CT wire is a high-strength carbon steel wire known for its durability and hardness, making it ideal for a range of industrial applications.

Q: What are the main applications of 45CT wire?

A: 45CT wire is used in the manufacturing of automotive parts, machinery, and structural components. It's also used for coatings in industries that require corrosion resistance and high-temperature performance.

Q: What are the key benefits of 45CT wire?

A: The key benefits include high strength, good hardness, excellent machinability, and versatility in various industries.

Q: How does 45CT wire perform under stress?

A: 45CT wire offers excellent tensile strength and durability, making it suitable for demanding applications that require performance under high stress.

Q: Is 45CT wire easy to work with?

A: Yes, 45CT wire is easy to cut, shape, and form, simplifying the manufacturing process and increasing efficiency.

Q: How should 45CT wire be stored?

A: Store 45CT wire in a dry, cool environment to prevent corrosion and maintain its high-quality properties.