Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Hastelloy Alloys

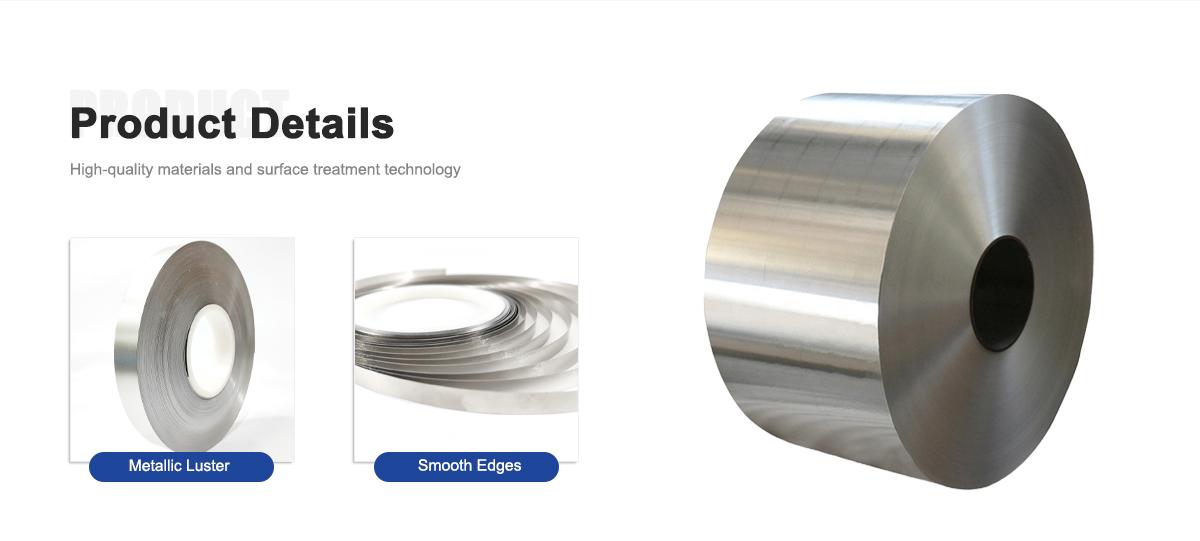

Product Details

Hastelloy C-276 is a versatile, nickel-based corrosion-resistant alloy known for its exceptional durability in severe operational conditions. Its optimized composition provides outstanding resistance to pitting, stress-corrosion cracking, and oxidizing atmospheres up to high temperatures. In hydrogen applications, this high-performance alloy is particularly valued for its superior resistance to hydrogen embrittlement—a common failure mode in standard stainless steels. This makes Hastelloy C-276 an indispensable material for ensuring the safety, longevity, and reliability of systems involved in green hydrogen production, storage, and distribution.

The superior performance of Hastelloy C-276 in hydrogen energy systems stems from its key characteristics:

Withstands exposure to high-pressure hydrogen environments, maintaining ductility and preventing catastrophic failure where other materials degrade.

Excellent resistance to a wide range of aggressive chemicals, including chlorides, sulfuric acid, and phosphoric acid, which may be encountered in hydrogen production processes.

This high-performance alloy can be readily welded and fabricated using standard techniques, allowing for the construction of complex components for hydrogen transport and storage vessels.

Retains its mechanical properties and corrosion resistance over a wide temperature range, suitable for various stages within the hydrogen energy value chain.

A long history of successful use in the most demanding chemical processing and aerospace industries, ensuring dependable performance in critical fuel cell applications.

| Hastelloy Grade | Hastelloy B | Hastelloy C-276 | Hastelloy C-4 | Hastelloy C-22 | Hastelloy C-59 | Hastelloy G | Hastelloy X |

| Corresponding brand | N10001/ NS321/ ONl65Mo28Fe5/ VN12MV | N10276 / 2.4819/ NS334 / CW12MW | N06455 / 2.4610I 00Cr16Ni65Mo16Ti / NS335 | N06022 / 2.4602/ NS3308 | N06059 / 2.4605/ NS3311 / Alloy59 | N06007 / 2.4618/ NS3402 | N06002 / 2.4665/ GH3536 / GH32 |

| Chemical composition% | |||||||

| C≤ | 0.05 | 0.01 | 0.015 | 0.015 | 0.01 | 0.05 | 0.05-0.15 |

| Mn≤ | 1 | 1 | 1 | 0.5 | 0.5 | 1.0-2.0 | 1 |

| P≤ | 0.04 | 0.04 | 0.04 | 0.02 | 0.015 | 0.04 | 0.04 |

| S≤ | 0.03 | 0.03 | 0.03 | 0.02 | 0.01 | 0.03 | 0.03 |

| Si≤ | 1 | 0.08 | 0.08 | 0.08 | 0.01 | 1 | 1 |

| Cr≤ | ≤1 | 14.5-16.5 | 14.0-18.0 | 14.0-18.0 | 22.0-24.0 | 21.0-23.5 | 20.5-23.0 |

| Ni≤ | the base | the base | the base | the base | the base | the base | the base |

| Mo | 26.0-30.0 | 15.0-17.0 | 14.0-17.0 | 12.5-14.5 | 15.0-16.5 | 5.5-7.5 | 8.0-10.0 |

| Cu | ≤0.50 | 1.5-2.5 | |||||

| N | W:3.0-4.5 | W:2.5-3.5 | W:≤1.0 | W:0.2-1.0 | |||

| Nb | 1.75-2.50 | ||||||

| Other | V:0.20-0.40 Co:≤2.50 Fe:4.0-60. | V:≤0.35 Co:≤2.50 Fe:4.0-7.0 | Ti:≤0.70 Co:≤2.0 Fe:≤3.0 | V:≤0.35 Co:≤2.5 Fe:2.0-6.0 | AI:0.10-0.40 Co:≤0.30 Fe:≤1.50 | Co:≤2.5 Fe:≤18.0-21.0 | Co:≤0.5-2.5 Fe:≤17.0-20.0 |

This hydrogen resistant alloy is specified for numerous critical applications within the hydrogen energy sector:

High-Pressure Hydrogen Storage Vessels and Cylinders

Piping and Tubing for Hydrogen Transport

Components within Electrolyzers for Green Hydrogen Production

Fuel Cell Stack Components and Bipolar Plates

Valves, Fittings, and Fasteners in Hydrogen Service

Compressor Parts for Hydrogen Refueling Stations

Founded in 2002, CHANGZHOU DLX ALLOY CO., LTD is a leading manufacturer specializing in the research and production of specialized alloy materials. Our factory has earned both the ISO9001 International Quality Management System Certificate and SGS Certification, affirming our commitment to high standards of quality.

We are experts in the entire alloy production process, including melting, drawing, heat treatment, finishing, and rigorous testing. Our product range includes nickel-based, copper-based, and iron-based alloys, such as super alloys, welding materials, anti-corrosion alloys, precision alloys, FeCrAl alloys, NiCr alloys, CuNi alloys, and thermocouples. These are available in various forms including wire, strip, ribbon, bar, tube, and plate.

A: Standard stainless steels are highly susceptible to hydrogen embrittlement, especially under high pressure, leading to loss of ductility and cracking. Hastelloy C-276, as a hydrogen resistant alloy, maintains its mechanical integrity and resembrittlement, ensuring long-term safety and reliability in hydrogen storage and transport systems.

A: Yes. Hastelloy C-276 retains excellent mechanical strength and corrosion resistance at elevated temperatures, making it suitable for various stages within hydrogen production and processing where heat is a factor.

A: We supply Hastelloy C-276 in various forms to meet your fabrication needs, including sheet, strip, plate, bar, wire, pipe, and tubing, specifically for hydrogen energy components.

A: Absolutely. Hastelloy C-276 is known for its excellent weldability. It can be readily fabricated using common welding methods without undergoing post-weld heat treatment, which is crucial for constructing large hydrogen transport and storage vessels.