Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Hastelloy Alloys

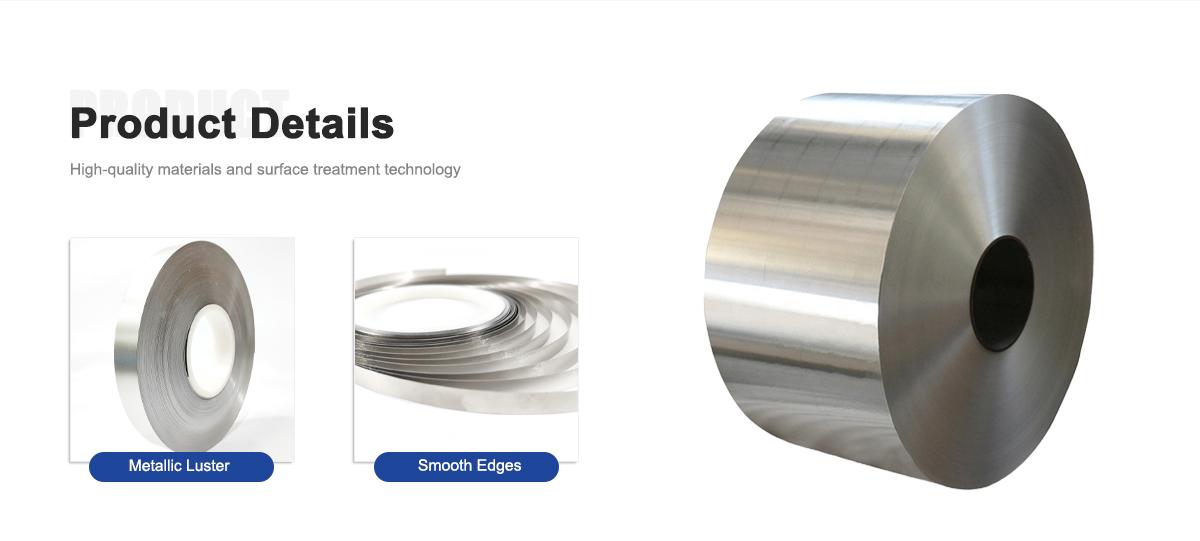

Product Details

Hastelloy C276 Hydrogen Cylinders and Valves are engineered for maximum safety and longevity in the hydrogen economy. As the industry moves towards higher pressures for efficient hydrogen storage and hydrogen transportation, the risk of hydrogen embrittlement in standard materials increases. Our Hastelloy C276 alloy provides an unmatched solution with its excellent resistance to a wide range of corrosive media, including wet chlorine, hypochlorite, and sulfuric acid, which can be present as impurities.

This material is specifically selected for Type IV hydrogen cylinders (with a polymer liner) for the metallic bosses and valves, and is fundamental in constructing the inner shells of stationary hydrogen storage tanks and the intricate components within hydrogen valves and regulators.

The superior performance of Hastelloy C-276 in hydrogen energy systems stems from its key characteristics:

Superior Resistance to Hydrogen Embrittlement: The primary reason for selecting Hastelloy C276 in hydrogen service. Its stable microstructure resects the degradation caused by high-pressure hydrogen, preventing crack initiation and propagation.

Excellent General Corrosion Resistance: Delivers outstanding performance in both oxidizing and reducing environments, making it ideal for hydrogen production, hydrogen storage, and hydrogen transportation where impurity gases may be present.

High Strength and Durability: Maintains excellent mechanical properties at a wide range of temperatures, from cryogenic conditions (as in liquid hydrogen storage) to moderately elevated temperatures, ensuring structural integrity.

Versatility in Fabrication: Hastelloy C276 can be readily welded and fabricated into complex shapes required for hydrogen cylinder necks, valve bodies, and other precision hydrogen components.

Long Service Life & Reliability: Reduces maintenance frequency and replacement costs, offering a total cost-of-advantage for critical hydrogen infrastructure.

| Hastelloy Grade | Hastelloy B | Hastelloy C-276 | Hastelloy C-4 | Hastelloy C-22 | Hastelloy C-59 | Hastelloy G | Hastelloy X |

| Corresponding brand | N10001/ NS321/ ONl65Mo28Fe5/ VN12MV | N10276 / 2.4819/ NS334 / CW12MW | N06455 / 2.4610I 00Cr16Ni65Mo16Ti / NS335 | N06022 / 2.4602/ NS3308 | N06059 / 2.4605/ NS3311 / Alloy59 | N06007 / 2.4618/ NS3402 | N06002 / 2.4665/ GH3536 / GH32 |

| Chemical composition% | |||||||

| C≤ | 0.05 | 0.01 | 0.015 | 0.015 | 0.01 | 0.05 | 0.05-0.15 |

| Mn≤ | 1 | 1 | 1 | 0.5 | 0.5 | 1.0-2.0 | 1 |

| P≤ | 0.04 | 0.04 | 0.04 | 0.02 | 0.015 | 0.04 | 0.04 |

| S≤ | 0.03 | 0.03 | 0.03 | 0.02 | 0.01 | 0.03 | 0.03 |

| Si≤ | 1 | 0.08 | 0.08 | 0.08 | 0.01 | 1 | 1 |

| Cr≤ | ≤1 | 14.5-16.5 | 14.0-18.0 | 14.0-18.0 | 22.0-24.0 | 21.0-23.5 | 20.5-23.0 |

| Ni≤ | the base | the base | the base | the base | the base | the base | the base |

| Mo | 26.0-30.0 | 15.0-17.0 | 14.0-17.0 | 12.5-14.5 | 15.0-16.5 | 5.5-7.5 | 8.0-10.0 |

| Cu | ≤0.50 | 1.5-2.5 | |||||

| N | W:3.0-4.5 | W:2.5-3.5 | W:≤1.0 | W:0.2-1.0 | |||

| Nb | 1.75-2.50 | ||||||

| Other | V:0.20-0.40 Co:≤2.50 Fe:4.0-60. | V:≤0.35 Co:≤2.50 Fe:4.0-7.0 | Ti:≤0.70 Co:≤2.0 Fe:≤3.0 | V:≤0.35 Co:≤2.5 Fe:2.0-6.0 | AI:0.10-0.40 Co:≤0.30 Fe:≤1.50 | Co:≤2.5 Fe:≤18.0-21.0 | Co:≤0.5-2.5 Fe:≤17.0-20.0 |

This hydrogen resistant alloy is specified for numerous critical applications within the hydrogen energy sector:

High-Pressure Hydrogen Storage Vessels and Cylinders

Piping and Tubing for Hydrogen Transport

Components within Electrolyzers for Green Hydrogen Production

Fuel Cell Stack Components and Bipolar Plates

Valves, Fittings, and Fasteners in Hydrogen Service

Compressor Parts for Hydrogen Refueling Stations

Excellent Corrosion Resistance: Outstanding performance in a wide range of harsh environments, including oxidizing and reducing media, such as wet chlorine, hypochlorite, and sulfuric acid.

Superior Resistance to Hydrogen Embrittlement: Maintains structural integrity and ductility in high-pressure hydrogen environments, making it a top choice for hydrogen storage and transport.

High Strength & Durability: Exhibits excellent mechanical properties and long-term stability across a broad temperature range, from cryogenic to moderately high temperatures.

Good Fabricability & Weldability: Can be readily formed and welded using standard techniques, facilitating the manufacturing of complex components.

Versatile Applications: Widely used in demanding industries such as chemical processing, pollution control, pulp and paper production, and the growing hydrogen energy sector.

Founded in 2002, CHANGZHOU DLX ALLOY CO., LTD is a leading manufacturer specializing in the research and production of specialized alloy materials. Our factory has earned both the ISO9001 International Quality Management System Certificate and SGS Certification, affirming our commitment to high standards of quality.

We are experts in the entire alloy production process, including melting, drawing, heat treatment, finishing, and rigorous testing. Our product range includes nickel-based, copper-based, and iron-based alloys, such as super alloys, welding materials, anti-corrosion alloys, precision alloys, FeCrAl alloys, NiCr alloys, CuNi alloys, and thermocouples. These are available in various forms including wire, strip, ribbon, bar, tube, and plate.

A: Standard stainless steels are highly susceptible to hydrogen embrittlement, especially under high pressure, leading to loss of ductility and cracking. Hastelloy C-276, as a hydrogen resistant alloy, maintains its mechanical integrity and resembrittlement, ensuring long-term safety and reliability in hydrogen storage and transport systems.

A: Yes. Hastelloy C-276 retains excellent mechanical strength and corrosion resistance at elevated temperatures, making it suitable for various stages within hydrogen production and processing where heat is a factor.

A: We supply Hastelloy C-276 in various forms to meet your fabrication needs, including sheet, strip, plate, bar, wire, pipe, and tubing, specifically for hydrogen energy components.

A: Absolutely. Hastelloy C-276 is known for its excellent weldability. It can be readily fabricated using common welding methods without undergoing post-weld heat treatment, which is crucial for constructing large hydrogen transport and storage vessels.

Previous article:Reliable Hastelloy C22 Solution for Hydrogen Infrastructure

Next article:Leading Supplier of Hastelloy C276 for Hydrogen Energy