Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Inconel bar & Rod

Product Details

Inconel 600 bars are a premium material designed for demanding applications in the chemical processing industry, particularly where high-temperature resistance and corrosion resistance are critical. With their excellent ability to withstand extreme heat and their robust mechanical properties, Inconel 600 bars are widely used in the manufacture of components for chemical reactors, heat exchangers, and various other industrial systems that need to endure aggressive environments.

Made from a nickel-chromium alloy, Inconel 600 bars deliver outstanding performance in both oxidizing and reducing environments, making them ideal for high-stress and high-temperature conditions commonly found in chemical processing plants.

Item | Inconel 600 | Inconel 625 | Inconel 718 | Inconel 825 | ||||

C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

Fe | 6-10 | rest | ≤3 | rest | 7-11 | rest | 5-9 | ≥22 |

P | ≤0.015 | ≤0.02 | ≤0.015 | -- | -- | -- | -- | -- |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

Cu | ≤0.5 | ≤1 | -- | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

Ni | ≥72 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

Co | -- | -- | 10-15 | ≤10 | -- | ≤1 | ≤1 | -- |

Al | -- | 1-1.7 | 0.8-1.5 | ≤0.8 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

Ti | -- | -- | ≤0.6 | ≤1.15 | -- | -- | 2.25-2.75 | 0.6-1.2 |

Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

Nb+Ta | -- | -- | -- | 4.75-5.5 | -- | 4.75-5.5 | 0.7-1.2 | -- |

Mo | -- | -- | 8-10 | 2.8-3.3 | -- | 2.8-3.3 | -- | 2.5-3.5 |

B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

Shape | Size (mm) |

Wire | 0.02-7.50 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Customized |

Sheet/Plate | Customized |

Exceptional Thermal Resistance:

Inconel 600 bars excel in high-temperature environments, withstanding temperatures up to 1,100°C (2,000°F) without significant loss of strength. This makes them ideal for chemical processing equipment and gas turbines.

Superior Corrosion Resistance:

The alloy is highly resistant to oxidation and corrosion, ensuring long-lasting performance in harsh environments where exposure to oxidizing acids, alkalis, and chlorides is common.

Outstanding Mechanical Strength:

Inconel 600 maintains excellent mechanical properties under high temperatures, offering high tensile strength and toughness. This is crucial for components exposed to mechanical stress, such as in the oil and gas industry.

Adaptable Fabrication:

The versatility of Inconel 600 allows it to be easily fabricated into bars, rods, plates, and other custom forms to suit various industrial applications, from aerospace to chemical processing.

Weldability:

Inconel 600 is compatible with conventional welding methods, allowing easy integration into complex systems and ensuring a secure connection in critical equipment.

Thermal Stability:

These bars perform well under fluctuating temperature conditions, maintaining their strength and stability, which is essential for high-performance applications such as heat exchangers and combustion chambers.

Long Service Life:

The combination of high corrosion resistance, thermal stability, and mechanical strength means that Inconel 600 bars have a longer operational lifespan, reducing the need for frequent replacements in demanding industrial environments.

Stress Corrosion Cracking Resistance:

Inconel 600 is engineered to resist stress corrosion cracking, making it suitable for high-stress environments like chemical reactors, where mechanical stress and harsh chemical exposure can lead to material degradation.

Chemical Compatibility:

Inconel 600's resistance to a broad range of chemicals ensures its longevity and reliability in industries where exposure to aggressive substances is common, such as in chemical processing or petrochemical plants.

1. Chemical Processing Equipment:

Inconel 600 bars are widely used in chemical processing industries for the construction of heat exchangers, reactors, and piping systems, where high-temperature performance and corrosion resistance are critical.

2. Aerospace Industry:

The high strength and heat resistance of Inconel 600 make it ideal for aerospace components, including turbine blades, exhaust systems, and other parts exposed to extreme thermal conditions.

3. Power Generation:

In gas turbines and other power generation equipment, Inconel 600 bars help maintain structural integrity and performance under high-temperature, high-stress conditions.

4. Marine Engineering:

The alloy’s excellent corrosion resistance makes Inconel 600 a popular choice for marine applications, such as seawater pumps and valves, that are exposed to corrosive marine environments.

5. Oil & Gas Industry:

Inconel 600 bars are used in downhole tubing and other high-stress components within the oil and gas industry, where they must endure extreme temperatures and aggressive environments.

6. Nuclear Power Industry:

Inconel 600 is used in nuclear reactors and heat exchangers, where its thermal stability and resistance to radiation-induced corrosion ensure safe and reliable performance.

Alloy Composition:

Nickel (Ni): 72% min

Chromium (Cr): 14-17%

Iron (Fe): 8-10%

Manganese (Mn), Silicon (Si), Carbon (C): Trace amounts

Other Elements: Small quantities of copper, molybdenum, and titanium

Physical Properties:

Density: 8.47 g/cm³

Melting Point: 1,395-1,455°C (2,543-2,651°F)

Tensile Strength: 1030 MPa (min)

Yield Strength: 450 MPa (min)

Elongation: 40% (min)

Hardness: Rockwell B 95 (max)

Temperature Resistance: Up to 1,100°C (2,000°F) with excellent retention of strength and integrity.

Weldability: Excellent weldability with standard methods like TIG, MIG, and stick welding.

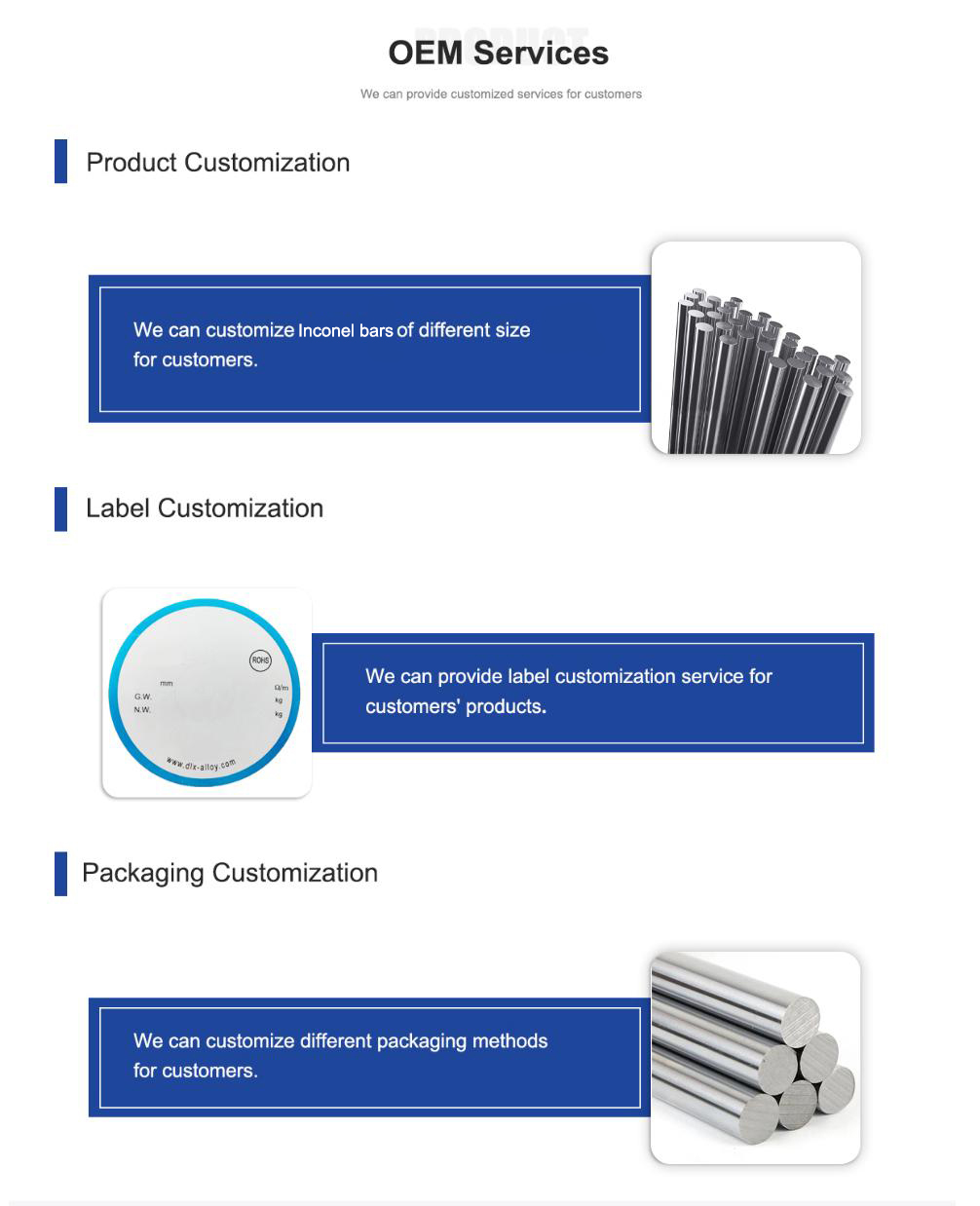

We provide tailored Inconel 600 bars in various diameters, lengths, and surface finishes to meet your specific needs. We also offer precision machining to fit your required dimensions and performance standards. Custom bar lengths and surface finishes such as polished or matte finishes are available upon request.

Packaging:

Inconel 600 bars are securely packaged in wooden crates or pallets with protective padding to ensure safe transit. The packaging is designed to prevent any damage or corrosion during shipping.

Shipping:

Shipping is handled through reputable courier services, and we provide shipping quotes based on your location and order size. Expedited shipping options are available upon request.

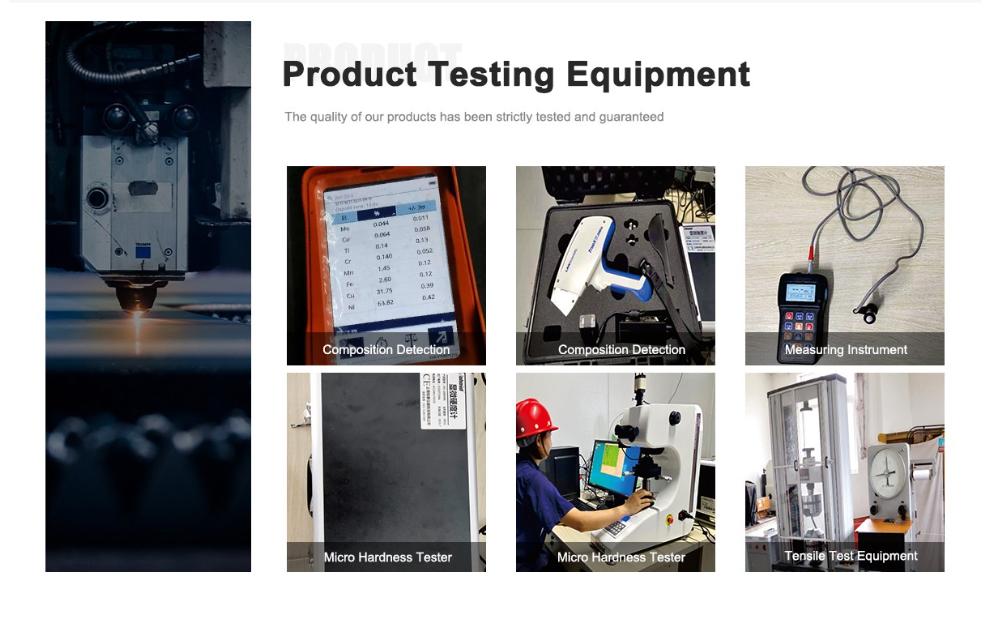

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got ISO9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, Precision Alloy , FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Q1: What industries can benefit from using Inconel 600 bars?

A1: Inconel 600 bars are widely used in industries such as chemical processing, aerospace, oil and gas, power generation, marine engineering, and nuclear power.

Q2: What is the maximum temperature Inconel 600 bars can withstand?

A2: Inconel 600 bars can withstand temperatures up to 1,100°C (2,000°F) without compromising their strength or integrity.

Q3: Can Inconel 600 bars be welded?

A3: Yes, Inconel 600 bars can be welded using standard techniques, such as TIG and MIG welding.

Q4: How long does it take to receive my order?

A4: The typical lead time for Inconel 600 bars is 7-15 days, depending on the quantity and customization requirements.

Q5: Do you offer custom sizes?

A5: Yes, we offer custom lengths, diameters, and surface finishes for Inconel 600 bars to meet your specific needs.

Previous article:Versatile Inconel 825 Bar for Marine Engineering Projects

Next article:Durable Inconel X-750 Bar for Power Generation in Gas Turbines