Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Inconel bar & Rod

Product Details

Inconel X-750 bars are highly sought-after materials in the power generation industry, especially in gas turbines. With remarkable high-temperature resistance, corrosion resistance, and mechanical strength, these bars are crucial in maintaining the performance and longevity of critical components such as turbine blades and combustion chambers. They are engineered to perform reliably under extreme conditions, ensuring optimal efficiency in aerospace, energy, and industrial applications.

Item | Inconel 600 | Inconel 625 | Inconel 718 | Inconel X750 | Inconel 825 | |||

C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

Fe | 6-10 | rest | ≤3 | rest | 7-11 | rest | 5-9 | ≥22 |

P | ≤0.015 | ≤0.02 | ≤0.015 | -- | -- | -- | -- | -- |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

Cu | ≤0.5 | ≤1 | -- | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

Ni | ≥72 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

Co | -- | -- | 10-15 | ≤10 | -- | ≤1 | ≤1 | -- |

Al | -- | 1-1.7 | 0.8-1.5 | ≤0.8 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

Ti | -- | -- | ≤0.6 | ≤1.15 | -- | -- | 2.25-2.75 | 0.6-1.2 |

Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

Nb+Ta | -- | -- | -- | 4.75-5.5 | -- | 4.75-5.5 | 0.7-1.2 | -- |

Mo | -- | -- | 8-10 | 2.8-3.3 | -- | 2.8-3.3 | -- | 2.5-3.5 |

B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

Shape | Size (mm) |

Wire | 0.02-7.50 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Customized |

Sheet/Plate | Customized |

High-Temperature Resistance: Inconel X-750 bars are designed to withstand temperatures up to 1800°F (982°C), making them ideal for high-temperature environments like gas turbines, jet engines, and industrial furnaces.

Corrosion Resistance: The alloy exhibits outstanding resistance to oxidation and corrosion, particularly in environments with exposure to harsh chemicals, saltwater, and high-pressure conditions.

Mechanical Strength: With superior tensile strength, Inconel X-750 maintains its structural integrity under both thermal and mechanical stresses, ensuring long-term reliability.

Excellent Weldability: Inconel X-750 bars can be easily welded using conventional methods like TIG and MIG welding, making them adaptable for complex engineering projects.

Stress Cracking Resistance: The alloy is engineered to resist stress corrosion cracking (SCC), which is essential in the oil and gas industry where components are subject to mechanical and thermal stresses.

Inconel X-750 bars are widely used in industries where high-performance, high-resistance materials are required. Here are some key application areas:

Gas Turbines & Power Generation

Inconel X-750 is essential in gas turbines for power generation, where it is used in components like turbine blades, combustion chambers, and nozzle assemblies that operate under extreme heat and high-pressure conditions.

Aerospace & Jet Engines

This alloy is a go-to material for aerospace applications, including the manufacturing of turbine blades and engine components that need to withstand thermal stresses and high velocities.

Oil and Gas Industry

Inconel X-750’s excellent corrosion resistance and high-temperature performance make it ideal for use in downhole tubing, pressure vessels, and other equipment exposed to corrosive fluids and high pressures in oil and gas extraction.

Marine Applications

Inconel X-750 is used in marine environments for parts like marine turbine blades and exhaust systems due to its ability to resist the corrosive effects of saltwater and high temperatures.

Petrochemical & Chemical Processing

In the chemical industry, Inconel X-750 is used for reactors, heat exchangers, and piping systems that are exposed to harsh chemicals and high temperatures, ensuring operational reliability and longevity.

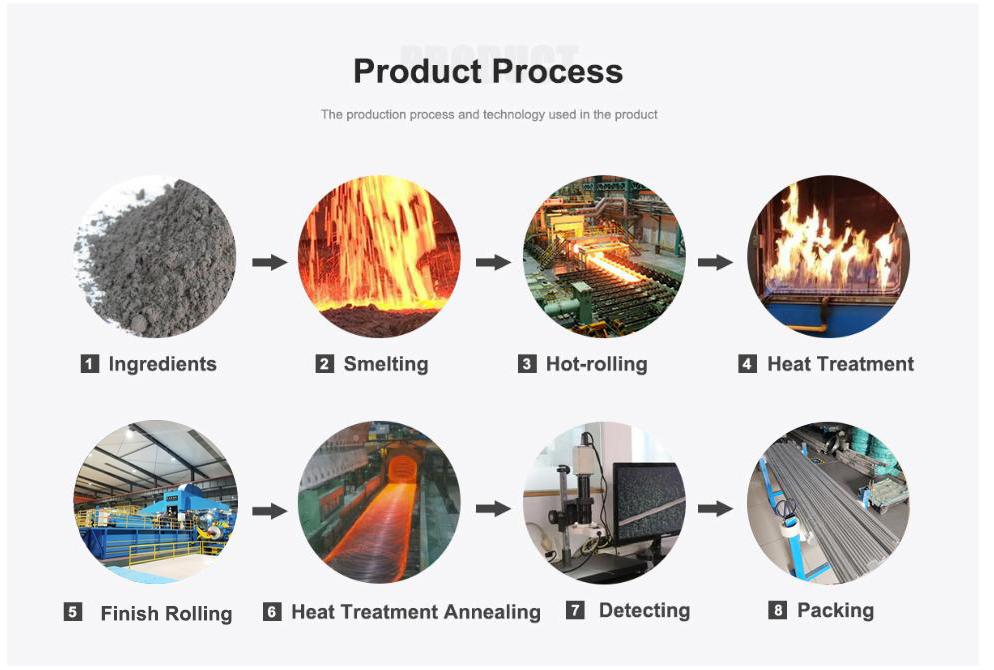

Inconel X-750 bars are manufactured using precise and controlled processes to ensure high-quality material properties:

Melting and Alloying: The process begins with melting the raw materials (nickel, chromium, and other alloying elements) in an electric arc furnace to create a homogeneous alloy mixture.

Hot Rolling: The molten metal is then hot-rolled into bars of the required size and shape. This process ensures that the material achieves the necessary grain structure for optimal mechanical properties.

Heat Treatment: The bars are subjected to heat treatment processes, including solution annealing and aging. These processes enhance the strength, ductility, and corrosion resistance of the alloy.

Cold Working: After heat treatment, the material may undergo cold working to further refine the structure and improve surface finish and tensile properties.

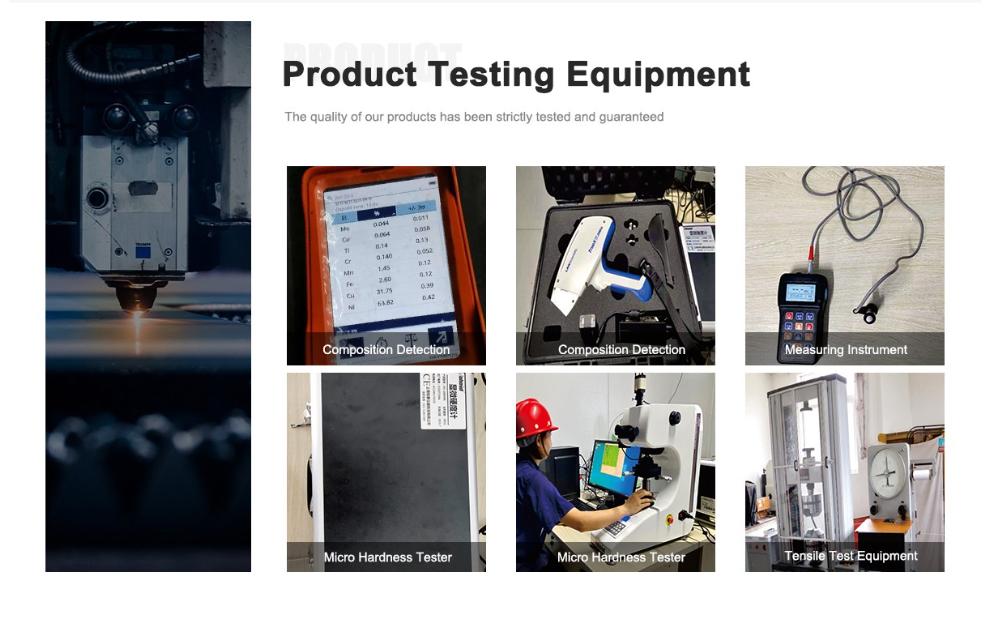

Inspection & Testing: Every batch of Inconel X-750 bars is rigorously inspected and tested to meet international standards. Tests include tensile strength, corrosion resistance, dimensional accuracy, and thermal stability to ensure top-quality performance.

Inconel X-750 bars offer numerous advantages in critical applications:

High-Temperature Stability: The material maintains its strength and structural integrity even at elevated temperatures, making it perfect for high-performance turbines and jet engines.

Corrosion and Oxidation Resistance: Ideal for environments exposed to harsh chemicals, saltwater, and high-pressure conditions, Inconel X-750 excels in corrosion resistance.

Robust Durability: With excellent tensile strength and creep resistance, these bars have an extended service life, reducing the frequency of repairs and downtime in industrial settings.

Adaptability: The material can be used in various forms—bars, rods, plates—allowing for versatility in engineering designs and manufacturing.

Stress Corrosion Cracking Resistance: Inconel X-750 bars can withstand the effects of stress corrosion cracking, which is common in industries like oil and gas, ensuring the longevity of critical equipment.

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got ISO9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, Precision Alloy , FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Q: What is Inconel X-750?

A: Inconel X-750 is a high-performance nickel-chromium alloy designed for use in high-temperature applications, offering exceptional corrosion resistance and mechanical strength. It is commonly used in gas turbines, jet engines, and other extreme conditions.

Q: How does Inconel X-750 perform in high-temperature environments?

A: Inconel X-750 can endure temperatures up to 1800°F (982°C), making it ideal for use in gas turbines, aerospace engines, and other components exposed to extreme heat.

Q: Can Inconel X-750 bars be welded?

A: Yes, Inconel X-750 bars are highly weldable using conventional techniques like TIG and MIG welding, making them adaptable for various engineering applications.

Q: What industries use Inconel X-750 bars?

A: Inconel X-750 is used across aerospace, power generation, oil and gas, marine, and chemical industries, where high strength, corrosion resistance, and heat resistance are crucial.

Q: What are your payment terms?

A: We accept T/T, L/C, D/A, D/P, Western Union, MoneyGram, and PayPal.

Q: What is the lead time for sample orders?

A: The typical lead time for sample orders is 7 days after payment confirmation.