Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Inconel Pipe

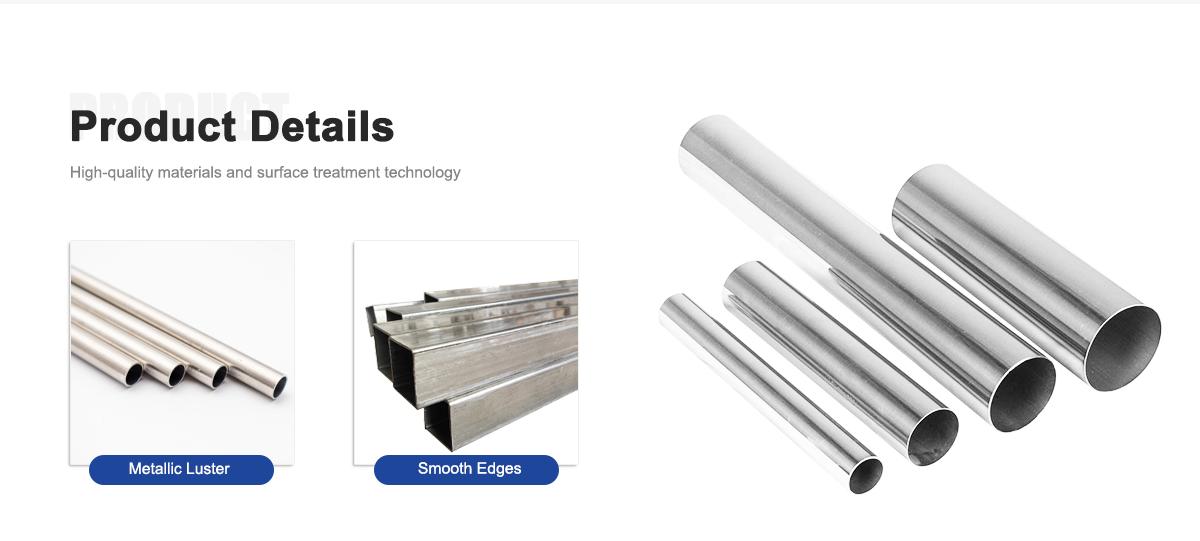

Product Details

Inconel 625 (UNS N06625) is a solid-solution strengthened nickel-based superalloy renowned for its exceptional combination of high strength, fabricability, and corrosion resistance. The addition of niobium and molybdenum provides remarkable resistance to pitting, crevice corrosion, and intergranular attack, making it the material of choice for hydrogen energy infrastructure.

In hydrogen systems, ordinary stainless steels suffer from severe hydrogen embrittlement and stress corrosion cracking under high pressure. DLX Inconel 625 seamless tubes eliminate these risks, offering proven performance in high-pressure hydrogen transportation pipelines, composite pressure vessels liners, hydrogen compressor components, and cryogenic liquid hydrogen transfer lines. DLX Alloy ensures strict quality control, full traceability, and third-party certification (TÜV, SGS, etc.) for every batch.

Outstanding resistance to pitting, crevice corrosion, and chloride stress corrosion cracking; excellent performance against hydrogen sulfide (H2S), CO2, and chloride-contaminated environments often present in hydrogen production.

Minimal susceptibility to hydrogen embrittlement even at pressures exceeding 100 MPa and cryogenic temperatures, ideal for Type IV hydrogen storage tanks and long-distance pipelines.

Minimum tensile strength 830 MPa (Grade 1 annealed) / 930 MPa (Grade 2 solution annealed); maintains mechanical properties from -196°C to 980°C.

Superior fatigue strength and creep rupture properties for cyclic loading in hydrogen refueling stations and transportation trailers.

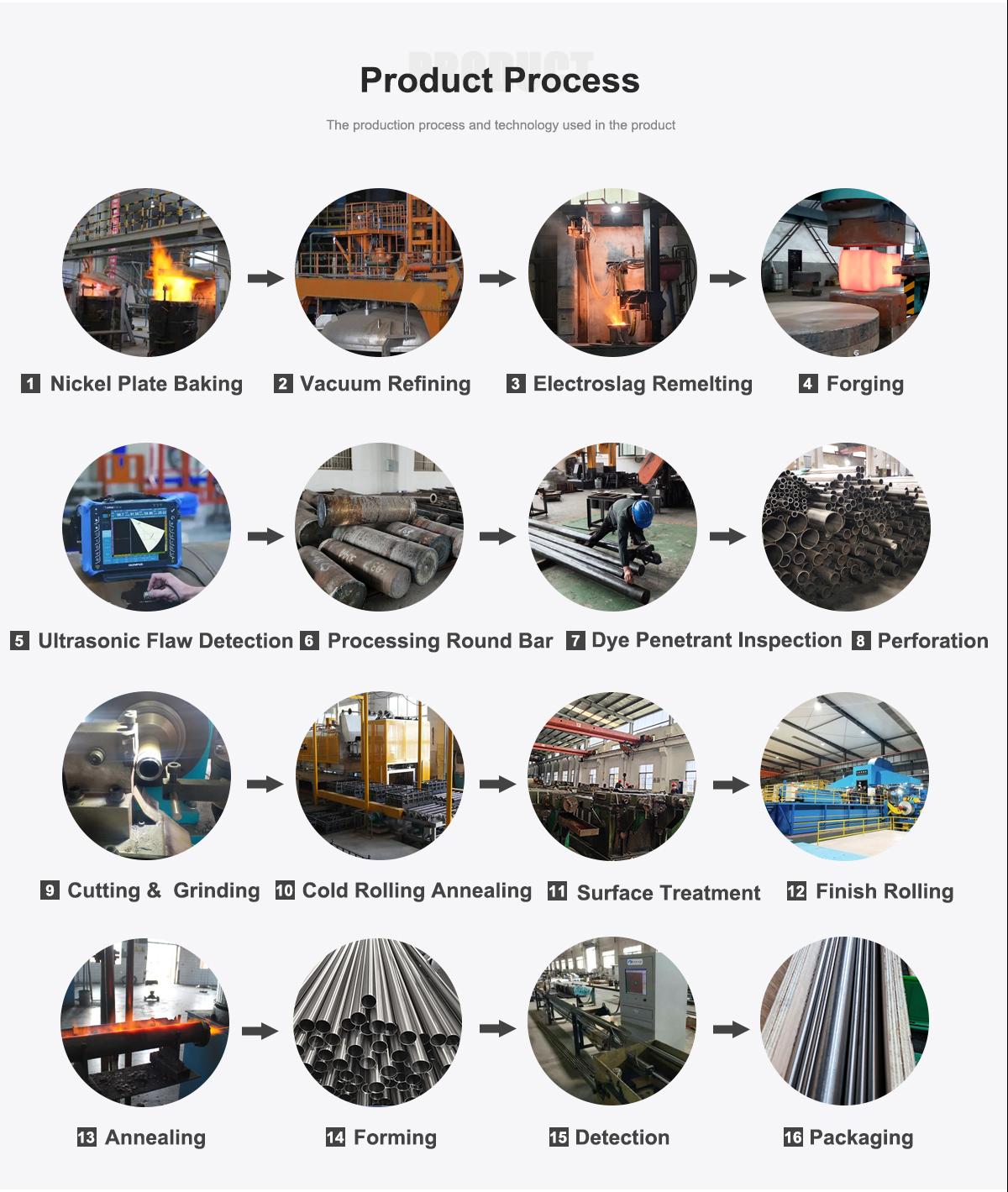

Cold-drawn seamless process ensures no weld seams, eliminating weak points and providing uniform wall thickness for high-pressure applications.

Suitable for cryogenic liquid hydrogen (-253°C) to high-temperature hydrogen processing.

Easy to weld using GTAW/TIG, GMAW/MIG without pre/post-heat treatment in most cases.

| Inconel Size Range | |

| Wire | 0.05-8.0mm |

| Rod/Bar | 8.0-200mm |

| Strip | (0.05-0.5)*(5-200)mm |

| Plate | custom made |

| Tube | custom made |

| Density | 8.40 g/cm3 |

| Ultimate Strength (≥ MPa) | 700 |

| Tensile Strength σb/MPa | 760 |

| Elongation δ5 (%) | 30 |

| Yield Strength σp0.2/MPa | 345 |

| Melting point | 1290-1350°C |

Inconel bars Chemical composition%

Liner material for Type III & Type IV high-pressure hydrogen storage tanks (700–1000 bar onboard vehicles and trailers)

Hydrogen transportation pipelines and tubing systems

Pressure vessels and accumulators in hydrogen refueling stations

Components for liquid hydrogen (LH2) storage tanks and transport dewars

Valves, fittings, flanges and seals in fuel cell and hydrogen compression systems

Cryogenic hydrogen pumps and heat exchangers

On-board hydrogen storage cylinders for fuel cell electric vehicles (FCEV)

Stationary hydrogen storage for renewable energy buffering

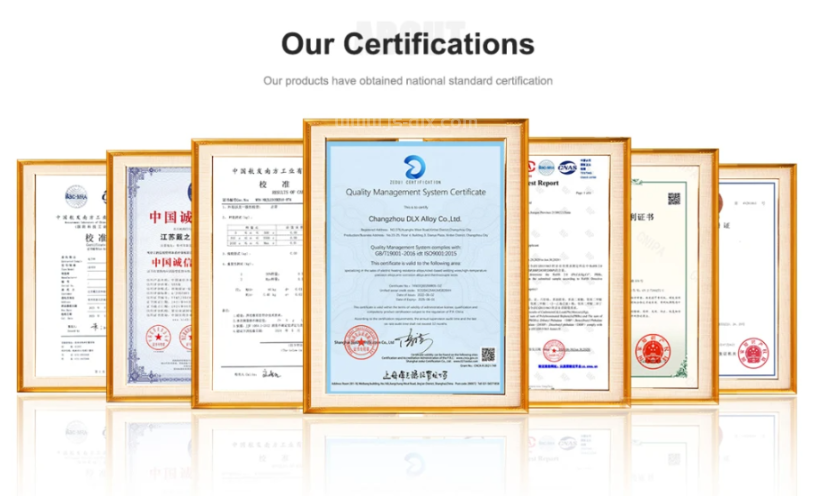

Founded in 2002, CHANGZHOU DLX ALLOY CO., LTD is a leading manufacturer specializing in the research and production of specialized alloy materials. Our factory has earned both the ISO9001 International Quality Management System Certificate and SGS Certification, affirming our commitment to high standards of quality.

We are experts in the entire alloy production process, including melting, drawing, heat treatment, finishing, and rigorous testing. Our product range includes nickel-based, copper-based, and iron-based alloys, such as super alloys, welding materials, anti-corrosion alloys, precision alloys, FeCrAl alloys, NiCr alloys, CuNi alloys, and thermocouples. These are available in various forms including wire, strip, ribbon, bar, tube, and plate.

A: 316L suffers severe hydrogen embrittlement above ~200 bar, while Inconel 625 remains unaffected even at 1000 bar and maintains higher strength, allowing thinner liners and lighter overall tank weight.

A: Yes, fully compliant with ISO 19881, ASME Section VIII Div. 3, and certified for gaseous hydrogen storage systems (GHS) and transportable tanks.

A: Absolutely. Its excellent low-temperature toughness and resistance to hydrogen attack make it ideal for cryogenic LH2 tanks and dewars.

A: Proven performance in commercial systems up to 1000 bar; DLX material has been qualified in multiple 700–900 bar onboard vehicle tanks.

A: Yes, we specialize in ultra-clean, low-roughness seamless tubes and sheets optimized for autofrettage and composite overwrapping.

A: Inconel 625 offers superior corrosion and hydrogen embrittlement resistance, while 718 provides higher strength after age-hardening. 625 is generally preferred for wet/corrosive hydrogen environments and as thin-wall liners.