Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Inconel Pipe

Product Details

DLX Premium Inconel 718 Tube & Pipe is a precipitation-hardenable nickel-chromium superalloy containing niobium, molybdenum, titanium, and aluminum. Known as GH4169 in China and UNS N07718 globally, it delivers the perfect combination of high yield strength (up to 1,200 MPa after age-hardening), excellent fatigue resistance, and robust corrosion/oxidation resistance – making it the material of choice for next-generation clean hydrogen infrastructure.

Ideal for hydrogen storage tanks, high-pressure hydrogen pipelines, hydrogen transport trailers, and hydrogen compressor/ valve components, our Inconel 718 tubes minimize the risk of hydrogen-induced cracking while maintaining structural integrity under extreme pressure (up to 700-1000 bar) and temperature cycling.

Outstanding Hydrogen Embrittlement Resistance — Virtually immune to hydrogen-induced cracking at pressures exceeding 1000 bar and temperatures from -253°C to 650°C

Exceptional Corrosion Resistance — Resists pitting, crevice corrosion and intergranular attack in hydrogen sulfide, chloride and acidic hydrogen environments

High Mechanical Strength — Yield strength 414–827 MPa (60–120 ksi), tensile strength >827 MPa (120 ksi), excellent fatigue life under cyclic pressure loading

Superior Weldability & Formability — Easily fabricated into seamless tubes, sheets and complex shapes without post-weld heat treatment

Wide Temperature Range — Maintains properties from cryogenic liquid hydrogen storage (-253°C) to high-temperature reforming processes

Long Service Life — Proven 20+ year performance in demanding hydrogen applications with minimal degradation

Certified Quality — Meets ASTM B444, B446, B564, B443, AMS 5599, 5666, ISO 6208 and NACE MR0175/ISO 15156 for hydrogen service

| Inconel Size Range | |

| Wire | 0.05-8.0mm |

| Rod/Bar | 8.0-200mm |

| Strip | (0.05-0.5)*(5-200)mm |

| Plate | custom made |

| Tube | custom made |

| Density | 8.40 g/cm3 |

| Ultimate Strength (≥ MPa) | 700 |

| Tensile Strength σb/MPa | 760 |

| Elongation δ5 (%) | 30 |

| Yield Strength σp0.2/MPa | 345 |

| Melting point | 1290-1350°C |

Inconel bars Chemical composition%

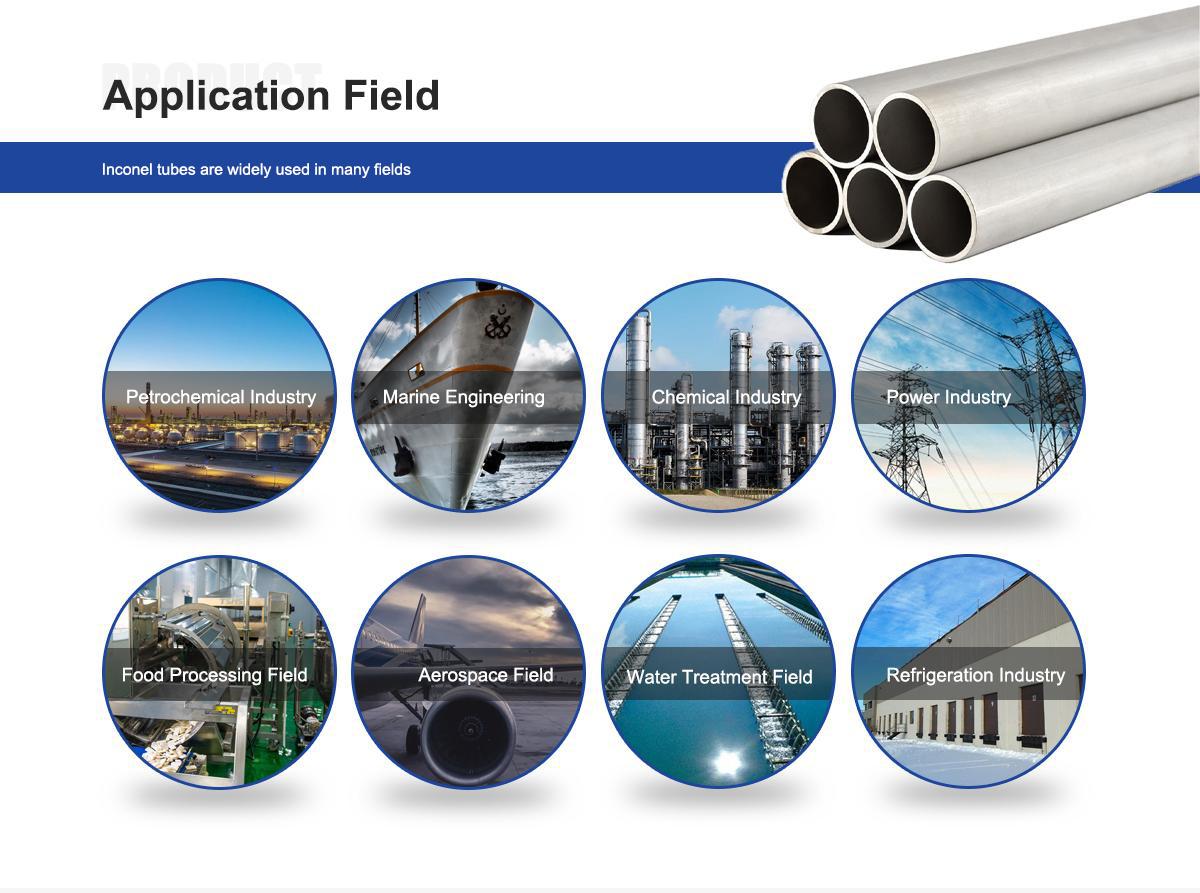

High-pressure gaseous hydrogen storage tanks (700–1000 bar)

Liners for Type IV composite hydrogen storage cylinders

Hydrogen transportation pipelines and trailer tubing

Components in hydrogen refueling stations (HRS)

High-pressure valves, fittings, and manifolds in fuel cell systems

Cryogenic hydrogen storage and transfer lines

On-board vehicle hydrogen tanks and fuel lines

Founded in 2002, CHANGZHOU DLX ALLOY CO., LTD is a leading manufacturer specializing in the research and production of specialized alloy materials. Our factory has earned both the ISO9001 International Quality Management System Certificate and SGS Certification, affirming our commitment to high standards of quality.

We are experts in the entire alloy production process, including melting, drawing, heat treatment, finishing, and rigorous testing. Our product range includes nickel-based, copper-based, and iron-based alloys, such as super alloys, welding materials, anti-corrosion alloys, precision alloys, FeCrAl alloys, NiCr alloys, CuNi alloys, and thermocouples. These are available in various forms including wire, strip, ribbon, bar, tube, and plate.

Q: Is Inconel 718 suitable for high-pressure hydrogen storage?

A: Yes. Inconel 718 (GH4169) exhibits excellent resistance to hydrogen embrittlement and is widely approved for gaseous hydrogen service up to 1000 bar and 700°C in standards like ASME and ISO 15156.

Q: What is the difference between Inconel 718 and Inconel 625 for hydrogen applications?

A: Inconel 718 offers much higher strength (especially after age-hardening) and better fatigue resistance, making it preferred for structural components like tank liners and pipelines. Inconel 625 has superior general corrosion resistance but lower strength.

Q: Can DLX supply Inconel 718 tubes certified for hydrogen service?

A: Absolutely. We provide material test certificates, hydrogen compatibility reports, and compliance with NACE/ISO requirements upon request.

Q: What heat treatment is recommended for hydrogen applications?

A: Solution-annealed + age-hardened (AMS 5663) condition provides the optimal balance of strength and hydrogen embrittlement resistance.

Q: Do you offer Inconel 625 (GH3625) tubes for hydrogen as well?

A: Yes, contact us for our dedicated Inconel 625 hydrogen-grade tubing solutions.