Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Inconel Strip

Product Details

Product Description

With a melting range of 1354-1413°C, Inconel 600 demonstrates exceptional resistance to oxidation and carburization in high-temperature environments. Its thermal expansion coefficient of 14.4 µm/m·K ensures dimensional stability under thermal stress. This non-magnetic alloy is widely used in furnace components, chemical processing equipment, and nuclear reactors, thanks to its high strength and corrosion resistance in both oxidizing and reducing atmospheres.

Beyond their exceptional temperature resistance, Inconel Alloys exhibit valuable non-magnetic properties, making them ideal for sensitive applications requiring electromagnetic neutrality. Their thermal efficiency is demonstrated by a heat capacity of 0.431 J/g-°C, enabling effective thermal energy management in demanding operational conditions.

These advanced materials find extensive application across multiple critical industries:

Aerospace systems benefit from their superior strength-to-weight ratio

Chemical processing equipment leverages their exceptional corrosion resistance

Nuclear power generation utilizes their radiation tolerance

Marine technologies employ them for seawater corrosion protection

For engineers specifying materials that must endure extreme thermal cycling and aggressive chemical exposure while maintaining structural integrity, Inconel alloys provide an optimal solution. Their engineered balance of:

Mechanical robustness

Thermal stability

Chemical inertness

makes them the material of choice for mission-critical applications where failure is not an option. The alloys' versatility extends across temperature extremes, from cryogenic conditions to high-heat environments, while maintaining consistent performance characteristics.

Detailed Photos

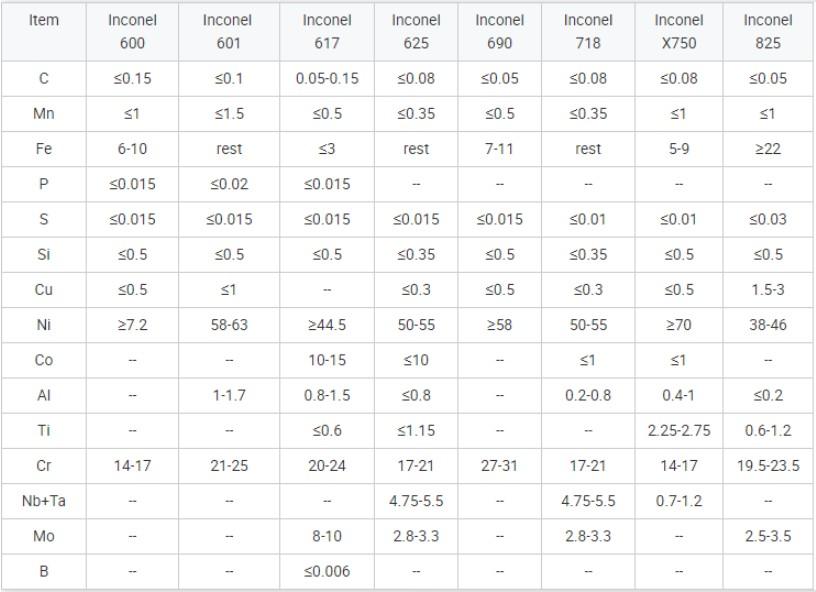

Product Parameters

Recommended products

Company Profile

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

Q: What is DLX Inconel Alloy?

A: DLX Inconel Alloy is a high-strength, nickel-based alloy that is resistant to extreme temperatures, corrosion, and oxidation. It is commonly used in aerospace, chemical processing, and nuclear engineering applications.

Q: Where is DLX Inconel Alloy manufactured?

A: DLX Inconel Alloy is proudly manufactured in China.

Q: What is the model number of DLX Inconel Alloy?

A: The model number of DLX Inconel Alloy is simply "Inconel Alloy."

Q: What are some of the key features of DLX Inconel Alloy?

A: DLX Inconel Alloy is known for its high strength, excellent resistance to corrosion and oxidation, and its ability to withstand extreme temperatures and pressure.

Q: In what industries is DLX Inconel Alloy commonly used?

A: DLX Inconel Alloy is commonly used in aerospace, chemical processing, and nuclear engineering industries due to its exceptional strength and resistance to extreme conditions.