Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Inconel Strip

Product Details

Product Description

Optimized for punishing environments, Inconel 718 delivers high tensile/yield strength at 700°C, with a melting range of 1260-1340°C. Strengthened by precipitation hardening, it resists oxidation and sulfidation, making it ideal for jet engines, rockets, and cryogenic hardware.

Non-magnetic traits cater to MRI tech and navigation devices. Its 0.431 J/g-°C heat capacity ensures thermal energy management.

Industry uses:

Aerospace (radiation-hardened components)

Oil/gas (sulfuric corrosion defense)

Power (high-temperature creep resistance)

Marine (deepwater hydrogen immunity)

Competitive edges:

Extreme stress rupture longevity

Thermal fatigue-resistant grain structure

Corrosion-inhibiting passive layer

Performance stability across temperature extremes

Vital for advanced hypersonics, molten salt reactors, and high-pressure acid systems, Inconel Alloys surpass traditional materials.

Detailed Photos

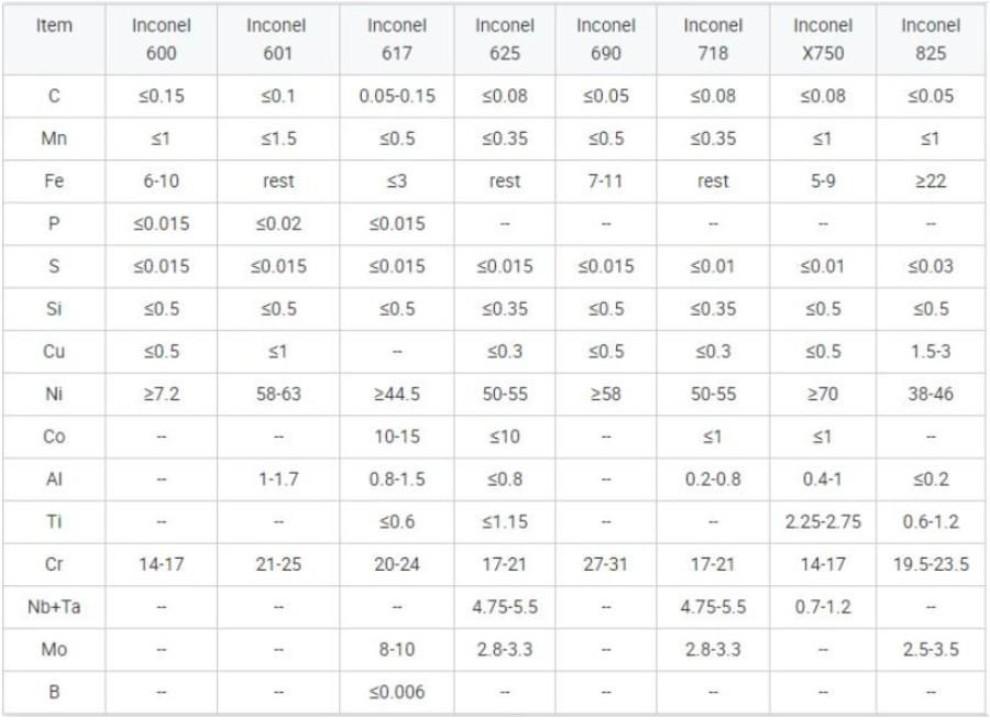

Product Parameters

Recommended products

Company Profile

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

Q: What is DLX Inconel Alloy?

A: DLX Inconel Alloy is a high-strength, nickel-based alloy that is resistant to extreme temperatures, corrosion, and oxidation. It is commonly used in aerospace, chemical processing, and nuclear engineering applications.

Q: Where is DLX Inconel Alloy manufactured?

A: DLX Inconel Alloy is proudly manufactured in China.

Q: What is the model number of DLX Inconel Alloy?

A: The model number of DLX Inconel Alloy is simply "Inconel Alloy."

Q: What are some of the key features of DLX Inconel Alloy?

A: DLX Inconel Alloy is known for its high strength, excellent resistance to corrosion and oxidation, and its ability to withstand extreme temperatures and pressure.

Q: In what industries is DLX Inconel Alloy commonly used?

A: DLX Inconel Alloy is commonly used in aerospace, chemical processing, and nuclear engineering industries due to its exceptional strength and resistance to extreme conditions.