Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

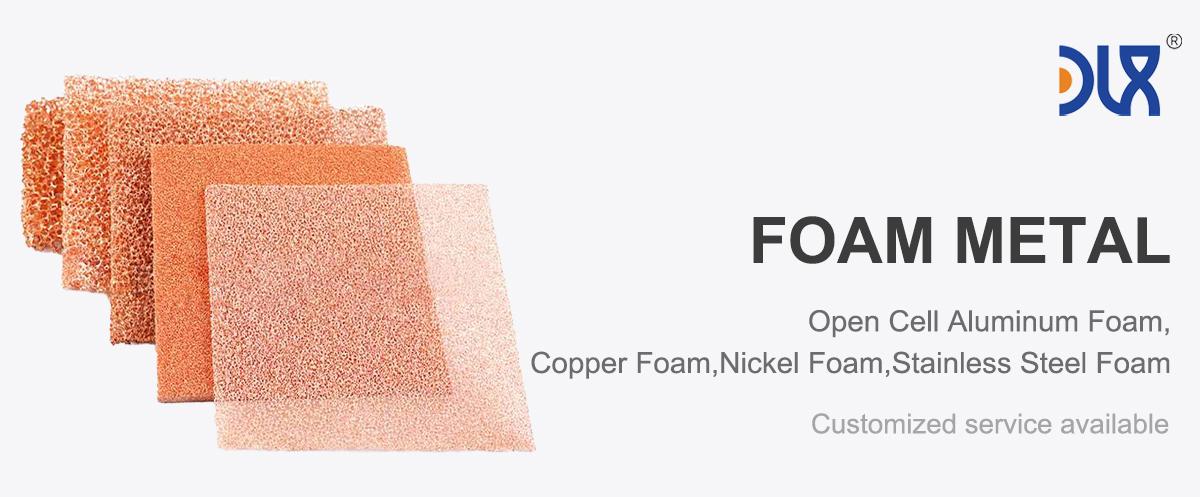

Metal Foam

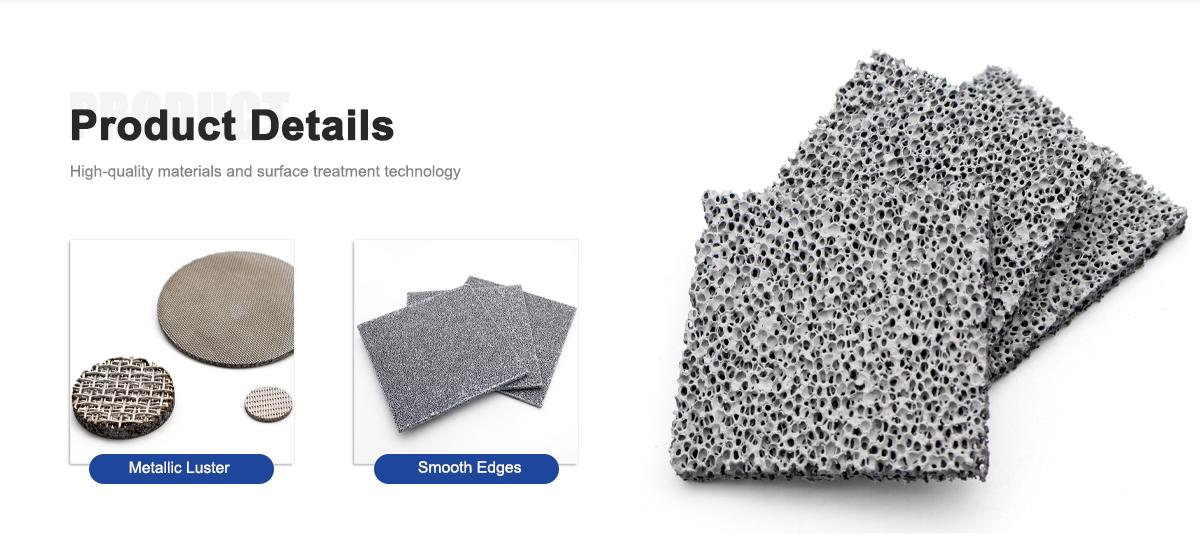

Product Details

Our high-quality Metal Foams, including Copper (Cu), Aluminum (Al), and Nickel (Ni) foams, are designed for advanced applications such as lithium batteries, electromagnetic shielding, and more. These foams provide excellent properties such as high strength, lightweight, and exceptional performance in thermal conductivity, electromagnetic interference (EMI) shielding, and sound absorption.

These porous materials, with their high surface area, are ideal for use in energy storage devices like lithium batteries, where they improve performance, enhance efficiency, and provide better heat dissipation. The metal foams are also widely used in electromagnetic shielding applications, where they protect sensitive components from harmful electromagnetic radiation.

Material | Nickel foam, Sold in sheet |

Dimension | 500*1000, or customized as request |

Thickness | 0.5mm, 1.0mm, 1.5mm, 2.0mm,3.00mm etc |

The aperture | 80 PPI (5-80 PPI available) |

Porosity | 90-98% |

Through Hole Rate | ≥98% |

Bulk density | 0.25-1.00g/cm3 |

Key Features:

Ultra-Light Weight: Metal foams offer a low specific gravity (0.2-0.3), making them significantly lighter than traditional materials such as wood, aluminum, or iron. This lightweight nature is perfect for energy-efficient applications.

Sound Absorption: With a porous structure, these foams exhibit excellent sound absorption properties, particularly effective at high frequencies. Sound insulation performance can be improved further with customized design features.

Electromagnetic Wave Shielding: The material offers about 90 dB electromagnetic shielding effectiveness through a relatively thin layer, making it suitable for electromagnetic interference (EMI) shielding in sensitive electronic applications.

High Temperature Resistance: These metal foams are highly resistant to high temperatures, maintaining structural integrity at up to 1100°C and offering great thermal stability in extreme conditions.

Recyclability: Made from metal, our foams are fully recyclable, making them an eco-friendly solution that supports sustainability.

Thermal Conductivity: Their strong thermal conductivity ensures that the material can be used in heat exchangers and other heat management applications, providing excellent thermal dissipation.

Breathability and Filtration: The uniform three-dimensional network structure of metal foam allows for effective filtration of gas and fluid, ensuring stable and reliable flow in various applications.

Customizable: The foam can be easily processed to meet specific requirements. It can be cut, bent, or adapted into different shapes, and its aperture can be customized between 0.05mm-25mm with porosity ranging from 50%-98%.

Wide Range of Applications: Our metal foam materials are ideal for energy storage in lithium batteries, electromagnetic shielding for electronic devices, sound insulation, and heat dissipation in a variety of industrial processes.

Applications:

Lithium Battery Materials: Metal foams, especially nickel foams, are used in the energy storage industry for battery electrodes and heat dissipation, improving the efficiency and lifespan of lithium-ion batteries.

Electromagnetic Shielding: These foams are perfect for protecting sensitive components in electronic devices, preventing electromagnetic interference (EMI) from disrupting performance.

Filter Materials: The high porosity and stability make metal foams an excellent choice for filtration applications, particularly in environments where fluids or gases need to be filtered.

Heat Management: Due to their strong thermal conductivity, metal foams are widely used in heat exchangers, radiators, and other thermal management systems to enhance energy efficiency.

Sound Insulation: Metal foams can be used in noise reduction applications, including industrial and commercial settings, offering superior soundproofing capabilities.

Specifications:

Aperture: 0.05mm-25mm (customizable)

Porosity: 50%-98%

Through Porosity: ≥98%

Bulk Density: 0.1-0.8 g/cm³

PPI (Pores per inch): 5-120

Form: Customized sizes and shapes available

Temperature Resistance: ≥1100°C

Thermal Conductivity: >3 W/m.K

Packaging and Delivery:

Packaging: Cartons or wooden cases, ensuring safe and efficient delivery.

Delivery: Lead time typically takes 20-30 days, depending on the order size.

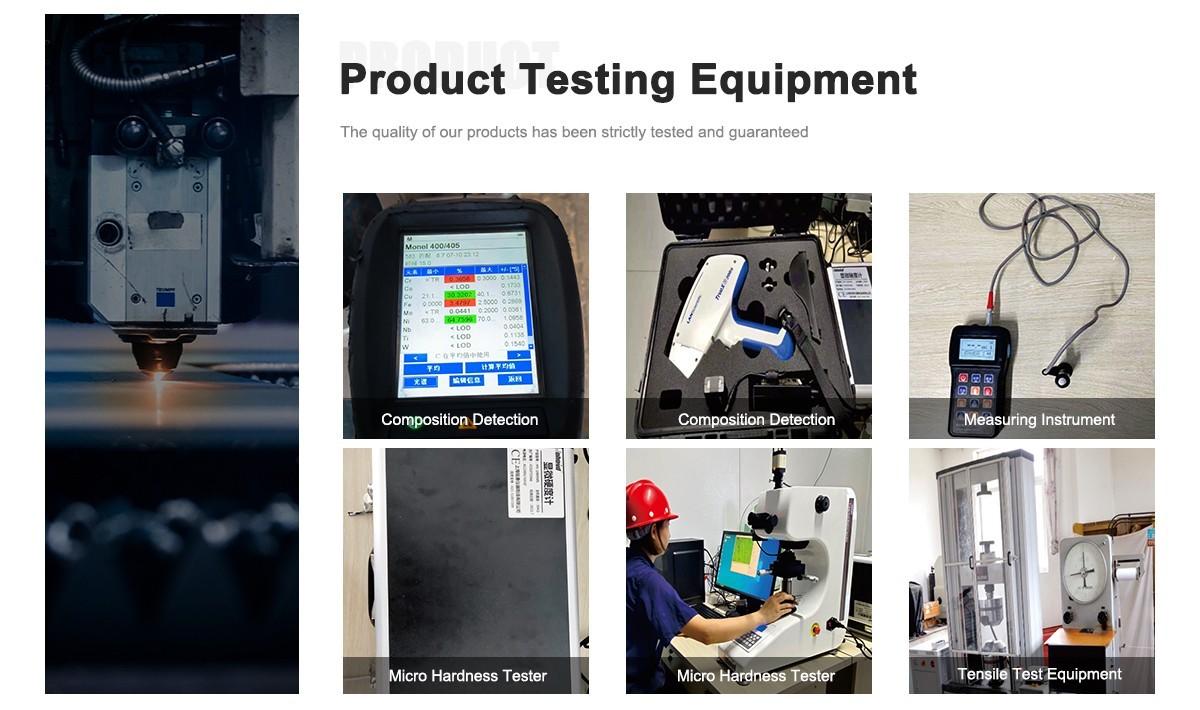

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got ISO9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, Precision Alloy , FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

FAQ:

How can I contact your company?

We are available through email, phone, fax, Skype, WhatsApp, WeChat, or mobile phone. Feel free to reach out through your preferred method.

What are your working hours?

Monday-Saturday: 7:30 AM - 5:00 PM (Beijing time, GMT+08:00). We observe public holidays during May 1-3, Oct 1-7, and Chinese New Year. Please email us during holidays if you have any questions.

Do you provide free samples?

Yes, we offer free samples for testing, though buyers are responsible for the shipping costs.

What are your payment terms?

We accept T/T, L/C, D/A, D/P, Western Union, MoneyGram, and PayPal.

What is the lead time?

Sample lead time is typically 7 days after payment confirmation. For large orders, delivery times may vary but are generally around 20-30 days.