Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

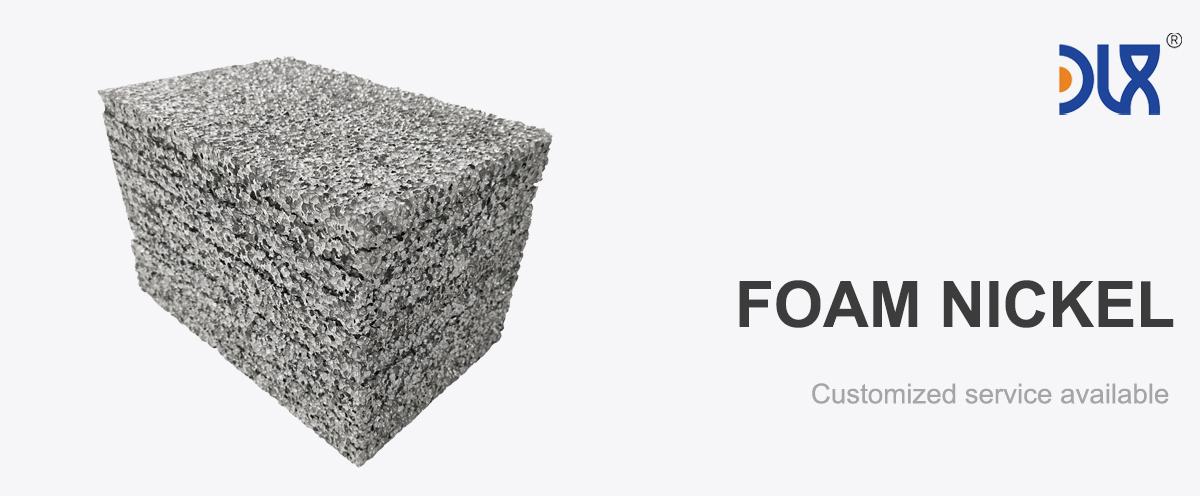

Metal Foam

Product Details

Nickel foam is an advanced, spongy porous metal known for its exceptional performance in a wide range of applications, including electromagnetic shielding, filtering, sound absorption, and heat dissipation. Its unique porous structure provides a high surface area, making it ideal for use in industries such as electronics, hydrogen storage, chemical processing, and many others.

As a versatile material, nickel foam offers outstanding thermal conductivity, sound absorption, and electromagnetic wave shielding, making it an indispensable component in various fields. It can also function as a catalyst carrier, a filter for fluid systems, and a magnetic flow conductor for magnetic particles.

Our nickel foam is designed to meet customized specifications, ensuring maximum performance and efficiency for your specific requirements.

Material | Nickel foam, Sold in sheet |

Dimension | 500*1000, or customized as request |

Thickness | 0.5mm, 1.0mm, 1.5mm, 2.0mm,3.00mm etc |

The aperture | 80 PPI (5-80 PPI available) |

Porosity | 90-98% |

Through Hole Rate | ≥98% |

Bulk density | 0.25-1.00g/cm3 |

Lightweight and High Surface Area:

Nickel foam is extremely lightweight with a specific gravity of 0.2-0.3, making it significantly lighter than wood, aluminum, and iron, providing more efficient performance in various applications.

Superior Sound Absorption:

With a porous structure, nickel foam exhibits excellent sound absorption properties, especially at high frequencies, and can be further optimized for low frequencies by modifying its sound-absorbing structure.

Electromagnetic Wave Shielding:

Nickel foam can shield electromagnetic waves effectively, offering a shielding effectiveness of approximately 90 dB with a thin material thickness, making it highly effective in electronic and communication devices.

Ease of Processing:

Nickel foam is easy to process, with the ability to be bent, lowered, and adhered to various surfaces, enabling easy integration into complex systems and designs.

High-Temperature Resistance:

It maintains its stable form even under extreme temperatures up to 1100°C, making it suitable for use in high-heat environments and applications that require thermal resistance.

100% Recyclable:

Nickel foam is environmentally friendly, as it can be fully recycled without any loss of quality, making it a sustainable option for industries concerned with waste reduction.

Strong Thermal Conductivity:

The high thermal conductivity of nickel foam makes it an ideal choice for heat exchange applications, allowing efficient heat dissipation and temperature regulation.

Breathability and Filtration:

Nickel foam features a uniform, three-dimensional network structure, which ensures stable gas and fluid flow, making it highly effective as a filter material in fluid filtration systems.

Insulation and Noise Shielding:

Additional processing can enhance its sound insulation properties, offering excellent noise reduction and heat shielding for industrial applications.

Aesthetic and Practical:

Nickel foam can be treated to improve its appearance, making it suitable for interior decoration and various design purposes while still maintaining its functional properties.

Aperture:

0.05mm - 25mm (Customizable to meet specific requirements)

Porosity:

50% - 98%

Through Porosity:

≥98%

Bulk Density:

0.1 - 0.8 g/cm³

PPI (Pores Per Inch):

5 - 120

Size:

Custom sizes available to meet project-specific needs

Nickel foam is used in various industries for a wide range of applications:

Electromagnetic Shielding:

Protects sensitive electronics and components from electromagnetic interference (EMI), ensuring the smooth functioning of devices in high-frequency environments.

Sound Absorption:

Used in noise control solutions for applications that require superior sound absorption, such as in industrial environments, audio equipment, and automotive industries.

Filtration and Fluid Flow:

Acts as a filter material for gases and liquids, ensuring efficient filtration while maintaining high flow rates.

Heat Dissipation:

Ideal for heat exchange applications, nickel foam efficiently dissipates heat in systems such as heat exchangers, cooling systems, and electronic devices.

Catalyst Carriers:

Nickel foam is an excellent support material for catalytic processes, offering a large surface area and high porosity for optimal catalyst performance.

Hydrogen Storage Media:

Utilized as a storage medium for hydrogen gas, nickel foam's structure ensures efficient absorption and release in energy applications.

Why Choose DLX Nickel Foam?

Customizable Specifications:

We offer nickel foam in a wide range of apertures, porosity, and sizes to meet the specific needs of your project. Our flexible manufacturing process ensures that we can accommodate even the most demanding applications.

High-Quality Materials:

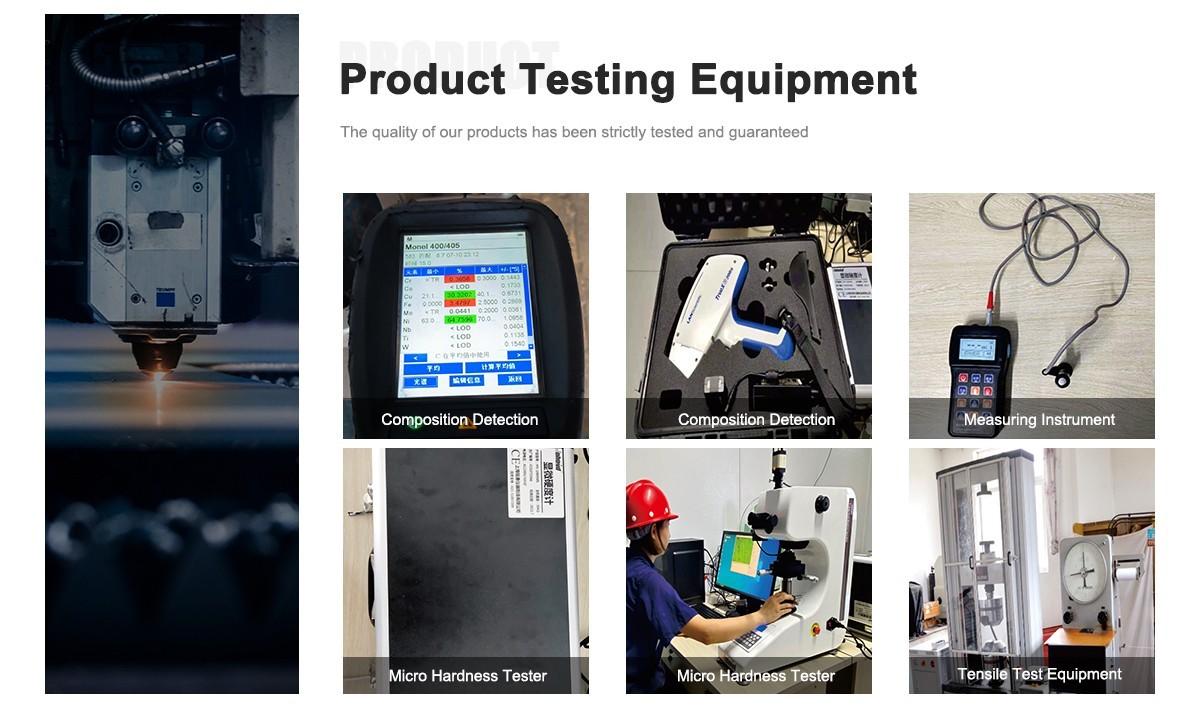

Our nickel foam is manufactured to the highest standards, ensuring superior performance and reliability. Each batch is rigorously tested for consistency and quality control.

Sustainability:

Nickel foam is 100% recyclable, making it an environmentally friendly choice for your business. By choosing our product, you contribute to sustainability without compromising on quality.

Technical Support:

Our experienced team is available to assist with product selection, application advice, and customization, ensuring you get the best results for your specific requirements.

Packaging:

Nickel foam is securely packed in cartons or wooden cases to protect it during transit. Custom packaging options are available upon request.

Shipping:

We provide reliable shipping solutions to ensure timely delivery to your location. Shipping costs will vary based on the order size and destination. A tracking number will be provided for your convenience.

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got ISO9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, Precision Alloy , FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications. We also provide chemical analysis reports for every FeCrAl alloy, NiCr alloy, and other products purchased.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

1. How can I contact your company?

You can contact us via email, telephone, fax, Skype, WhatsApp, WeChat, or mobile phone. We are always ready to assist you with your inquiries.

2. What are your working hours?

Our working hours are Monday to Saturday, 7:30 AM to 5:00 PM (Beijing time, GMT+08:00). We have public holidays during May 1-3, October 1-7, and Chinese New Year. Please feel free to email us during these times if you have any urgent questions.

3. Do you provide free samples?

Yes, we offer free samples for testing. However, buyers are responsible for the shipping costs.

4. What are your payment terms?

We accept various payment methods, including T/T, L/C, D/A, D/P, Western Union, MoneyGram, and PayPal.

5. What is the lead time for delivery?

The lead time for samples is typically 7 days after payment confirmation. Bulk orders may take longer depending on customization and order volume.