Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Nitinol Wires

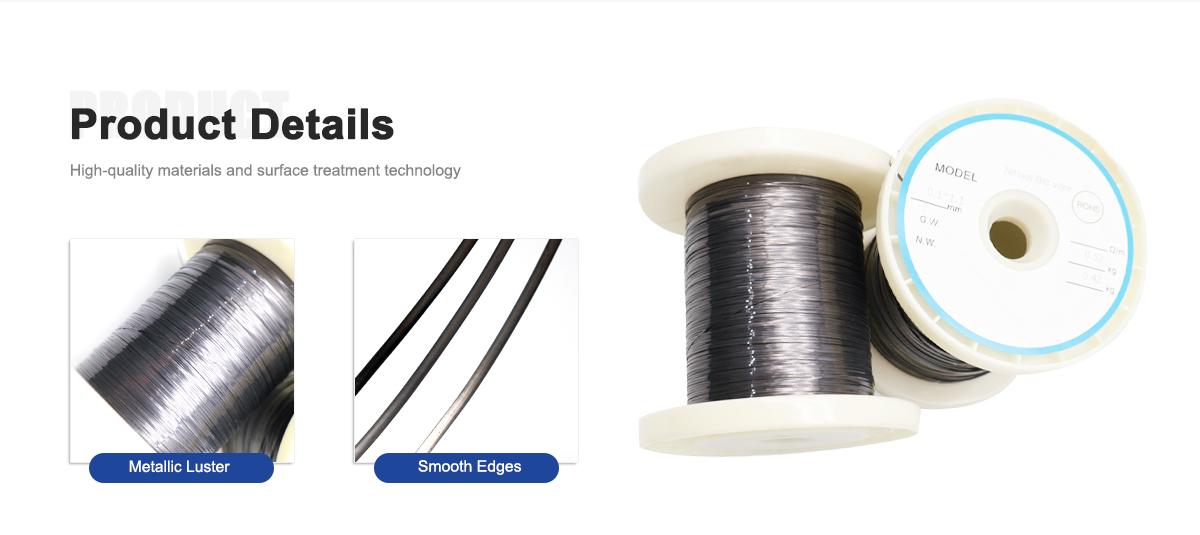

Product Details

Nitinol wire, a premium nickel-titanium alloy (approximately 55% nickel, 45% titanium), is celebrated for its unique shape memory effect and superelasticity. This advanced material effortlessly returns to its original shape upon heating, making it indispensable for medical devices, aerospace components, and smart actuators. Our medical-grade Nitinol wire is meticulously crafted to deliver superior performance in minimally invasive surgeries and precision engineering applications.

Shape Memory Effect: Restores pre-defined shape when heated above its Austenite finish temperature (Af), enabling >8% strain recovery for stents and actuators.

Superelasticity: Offers exceptional flexibility with recoverable strains up to 10%, ideal for kink-resistant guidewires and dynamic structures.

Biocompatibility: No tissue rejection or metallic ion release, ensuring safety for implants like orthodontic arches and vascular stents.

Corrosion Resistance: Withstands harsh environments like acids and seawater, providing a lifespan >12x that of traditional alloys.

High Strength-to-Weight Ratio: Matches steel’s strength while being 40% lighter, perfect for lightweight aerospace and wearable designs.

Broad Temperature Range: Operates reliably from -200°C to 550°C, suitable for extreme conditions in industrial applications.

Precision Manufacturing: Supports ultra-fine diameters (down to Ø0.02mm) and advanced processing like braiding for complex medical and robotic applications.

Applications of Nickel-Titanium Wire (Nitinol)

Aerospace Applications

Structural Components: In the aerospace industry, weight reduction is paramount. NiTi’s lightweight yet strong properties make it ideal for structural components of aircraft, enhancing fuel efficiency and overall performance. Components like wing flaps and landing gear benefit significantly from its application.

Control Actuators: NiTi’s shape memory effect enables it to act as a highly efficient actuator in control systems. When heated, it can change shape, allowing for precise adjustments in aerodynamic surfaces, contributing to improved flight stability and control.

Detailed Photos

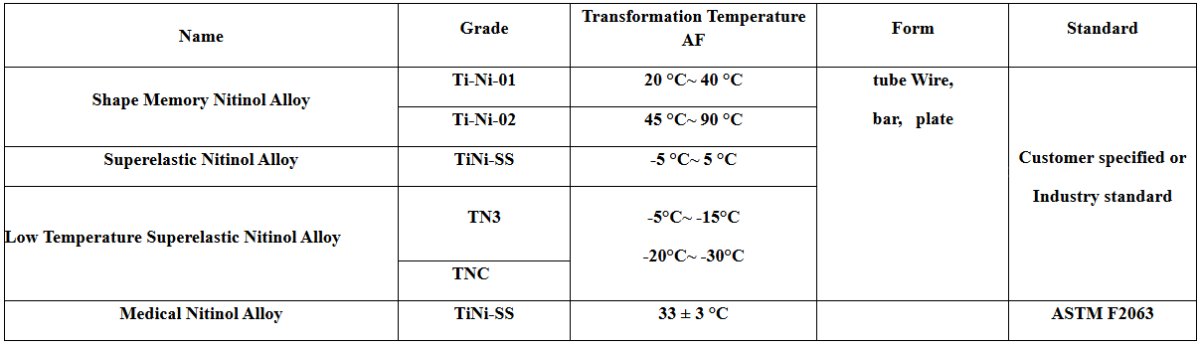

Product Parameters

Recommended products

Company Profile

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

If any requirements and questions, please feel free to reach:

Sophie Wang | Sales +86 19906119641

International Sales Depart.

Jiangsu Victory Technology Co., Ltd

A: NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu

FAQ

Previous article:Flexible NiTi for Advancements in Wearable Technology

Next article:Wear-Resistant NiTi for Innovations in Manufacturing