Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Nitinol Wires

Product Details

Nitinol Wire, a high-performance nickel-titanium alloy, is renowned for its shape memory and superelastic properties. With a balanced composition of nickel (approx. 54-56%) and titanium, it excels in applications requiring shape recovery and flexibility, such as minimally invasive surgical tools, robotics, and automotive sensors. Our Nitinol wire is crafted to meet stringent quality standards, ensuring durability and precision for cutting-edge industries.

Shape Memory Effect: Returns to pre-defined shape upon heating above its transformation temperature, enabling >7% strain recovery for actuators.

Superelasticity: Offers remarkable kink resistance and recoverable strain, ideal for dynamic medical devices and flexible structures.

Biocompatibility: Certified for medical use with zero tissue rejection, perfect for stents, catheters, and orthodontic applications.

Superior Corrosion Resistance: Resists degradation in harsh chemical and marine environments, extending lifespan beyond traditional alloys.

High Strength-to-Weight Ratio: Provides strength comparable to steel but 45% lighter, supporting lightweight designs in aerospace and wearables.

Extreme Temperature Stability: Performs consistently from -150°C to 550°C, suitable for cryogenic and high-heat applications.

Precision Manufacturing: Available in ultra-fine diameters (down to 0.02mm) with advanced braiding and shaping for complex designs.

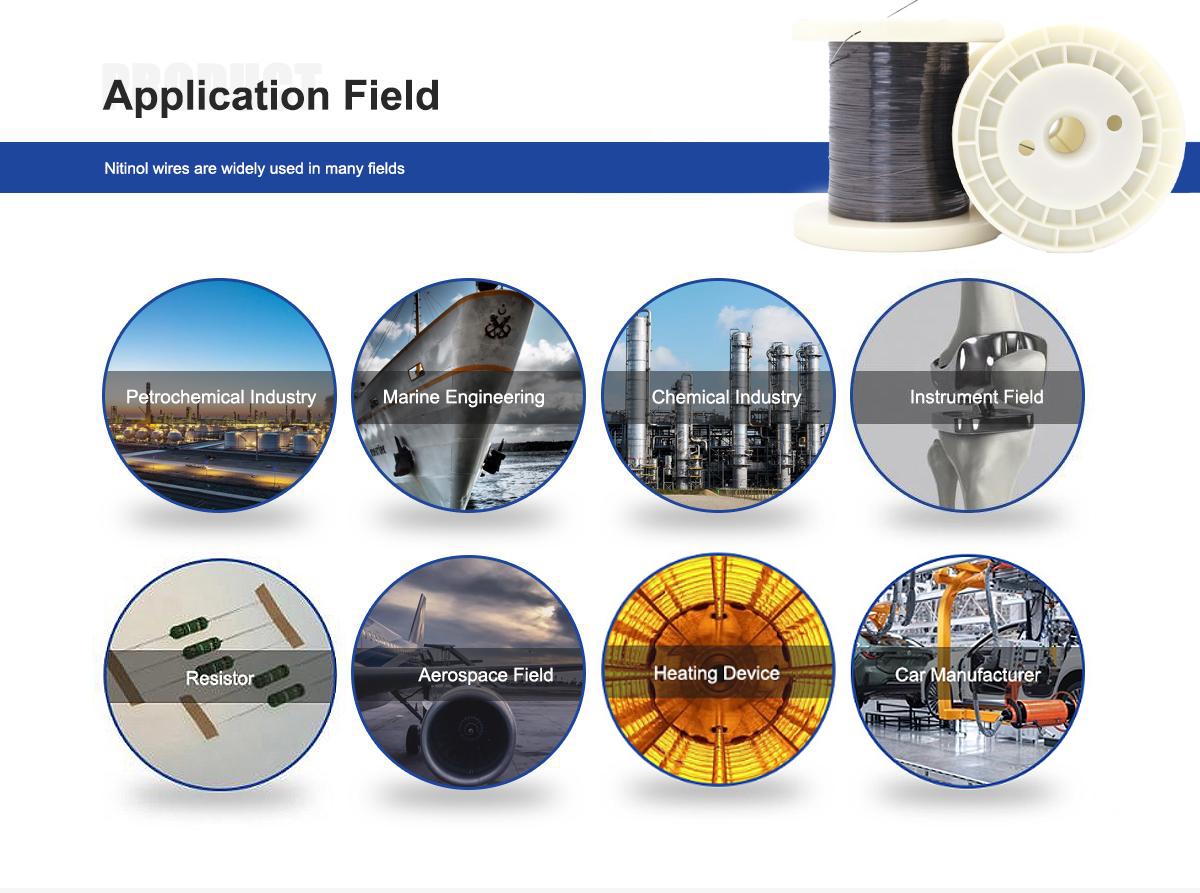

Applications of Nickel-Titanium Wire (Nitinol)

Automotive Applications

Shape Memory Alloys: In automotive applications, NiTi can be utilized in systems such as adaptive cruise control. Its ability to respond to environmental changes allows for seamless adjustments in vehicle components, enhancing safety and performance.

Suspension Systems: NiTi enhances automotive suspension systems by providing a dynamic response to road conditions. This leads to improved ride comfort, better handling, and an overall enhanced driving experience, making vehicles safer and more enjoyable to drive.

Detailed Photos

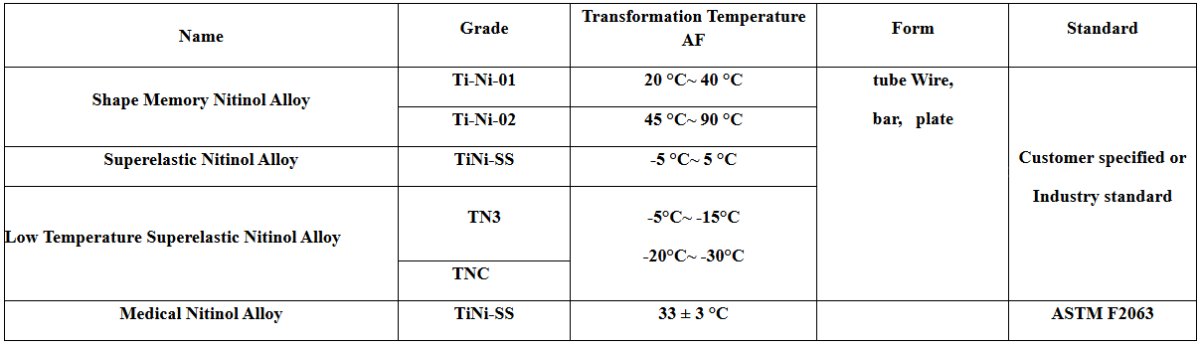

Product Parameters

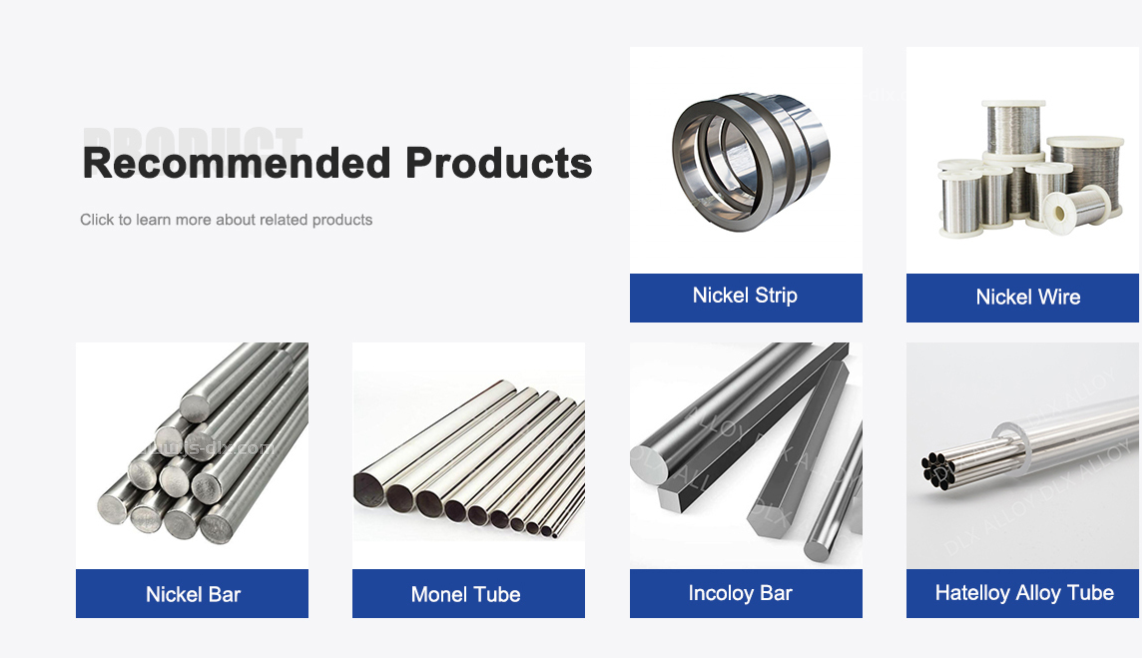

Recommended products

Company Profile

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

If any requirements and questions, please feel free to reach:

Sophie Wang | Sales +86 19906119641

International Sales Depart.

Jiangsu Victory Technology Co., Ltd

A: NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu

FAQ

Previous article:Smart-Responsive NiTi for Sensor Applications

Next article:Fatigue-Resistant NiTi for Enhancing Industrial Automation