Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

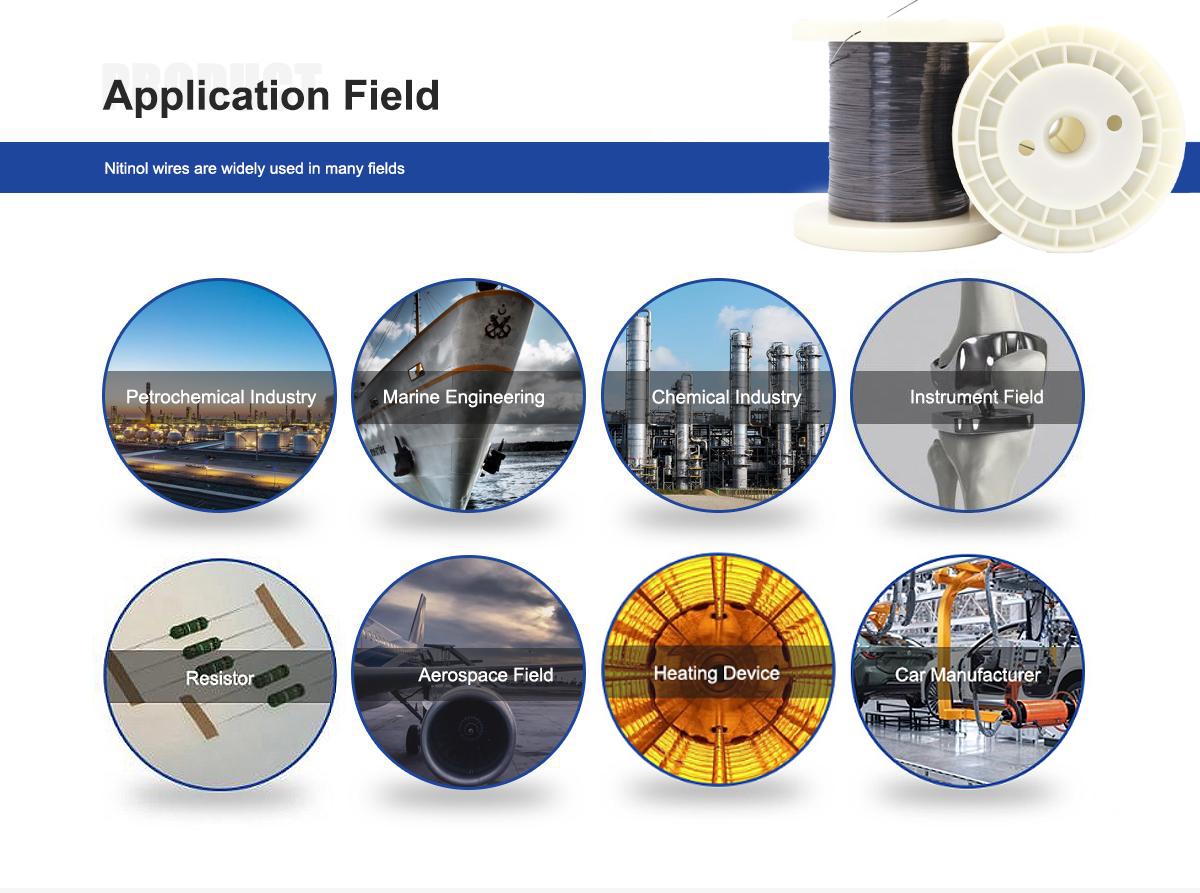

Nitinol Wires

Product Details

Nitinol wire, a remarkable nickel-titanium alloy, is renowned for its shape memory effect and superelasticity. This advanced material can return to its original shape after deformation when heated, making it ideal for applications in medical devices, aerospace, and automotive industries. Available in various diameters and grades, our Nitinol wire ensures high performance and reliability in demanding environments.

Shape Memory Effect: Returns to predefined shape upon heating.

Superelasticity: Exhibits exceptional flexibility and resilience without permanent deformation.

Biocompatibility: Safe for use in medical implants and devices.

Corrosion Resistance: Withstands harsh environments and chemicals.

High Strength-to-Weight Ratio: Lightweight yet durable for structural applications.

Self-Healing Materials: Research into NiTi’s potential for self-healing materials is promising. These materials could revolutionize product design, allowing items to recover from damage, thus extending their lifespan and reducing waste.

Eco-Friendly Solutions: NiTi is being explored for applications in renewable energy technologies, such as solar panels that can adjust their angle for optimal sunlight exposure, enhancing energy efficiency in sustainable solutions.

Orthopedic Devices: NiTi’s unique properties allow for the creation of implants and supports that adapt to body movements, providing better alignment and reducing discomfort for patients recovering from surgery or injury.

Assistive Devices: Innovations in assistive technologies using NiTi improve mobility for individuals with disabilities, allowing for devices that are both functional and comfortable, enhancing the quality of life.

Recommended products

Company Profile

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

If any requirements and questions, please feel free to reach:

Sophie Wang | Sales +86 19906119641

International Sales Depart.

Jiangsu Victory Technology Co., Ltd

A: NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu

FAQ

Previous article:Highly Conductive NiTi for Innovations in Electronic Devices

Next article:Eco-Friendly NiTi for Exploring Renewable Energy