Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Welcome to Changzhou DLX Alloy Co., Ltd.

Email:sales8@dlx-alloy.com Mobile/Whatsapp:+86 199 0611 9641

Specialized manufacturer of heaters, thermocouples and titanium,over 20 years.

Whatsapp:+86 199 0611 9641

Email:sales8@dlx-alloy.com

Add:NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu,China

Nitinol Wires

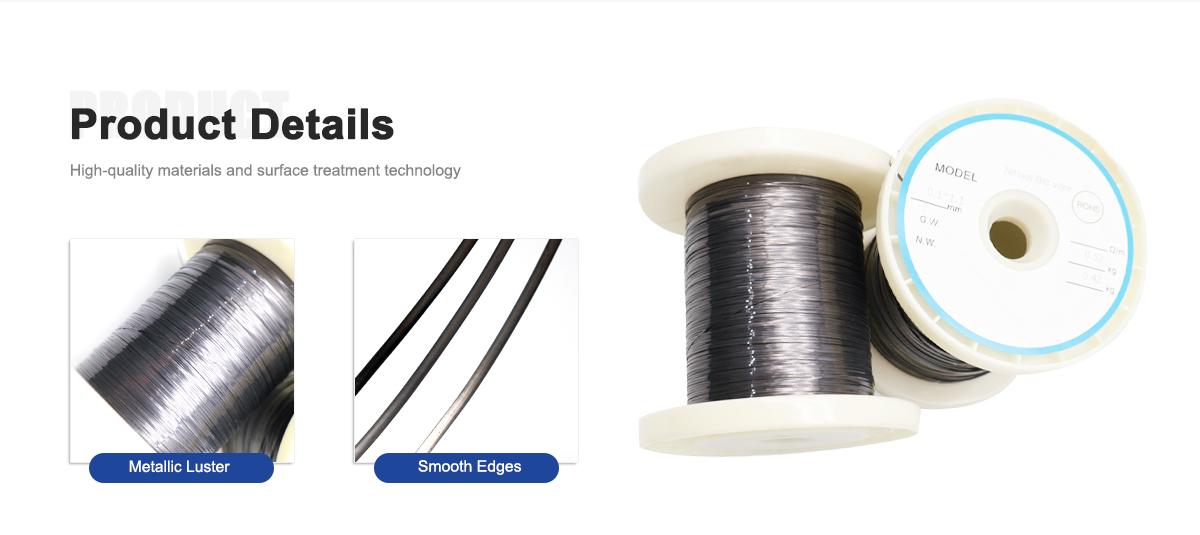

Product Details

Nitinol Wire, a premium nickel-titanium alloy, is celebrated for its unique shape memory effect and superelasticity. Composed of approximately 55% nickel and 45% titanium, this wire can revert to its original shape upon heating, making it a top choice for medical devices, aerospace components, and smart actuators. Our medical-grade Nitinol wire is engineered for precision, offering unmatched flexibility and reliability in critical applications such as stents and guidewires.

Shape Memory Effect: Recovers up to 8% strain when heated above its austenite finish temperature (Af), ideal for self-expanding structures and actuators.

Superelasticity: Provides exceptional elasticity with recoverable deformation, perfect for flexible medical tools and dynamic engineering solutions.

Biocompatibility: Non-toxic with no metallic ion release, ensuring safety for implants like orthodontic wires and vascular stents.

Corrosion Resistance: Withstands aggressive environments like acids and seawater, offering a lifespan up to 10 times longer than stainless steel.

Lightweight Strength: Matches high-strength alloys while being 40% lighter, enabling innovative designs in wearables and aerospace.

Broad Temperature Performance: Operates reliably from -200°C to 500°C, suitable for extreme conditions in industrial and medical settings.

Fine Processing Capability: Supports ultra-thin diameters and complex forming for precision applications.

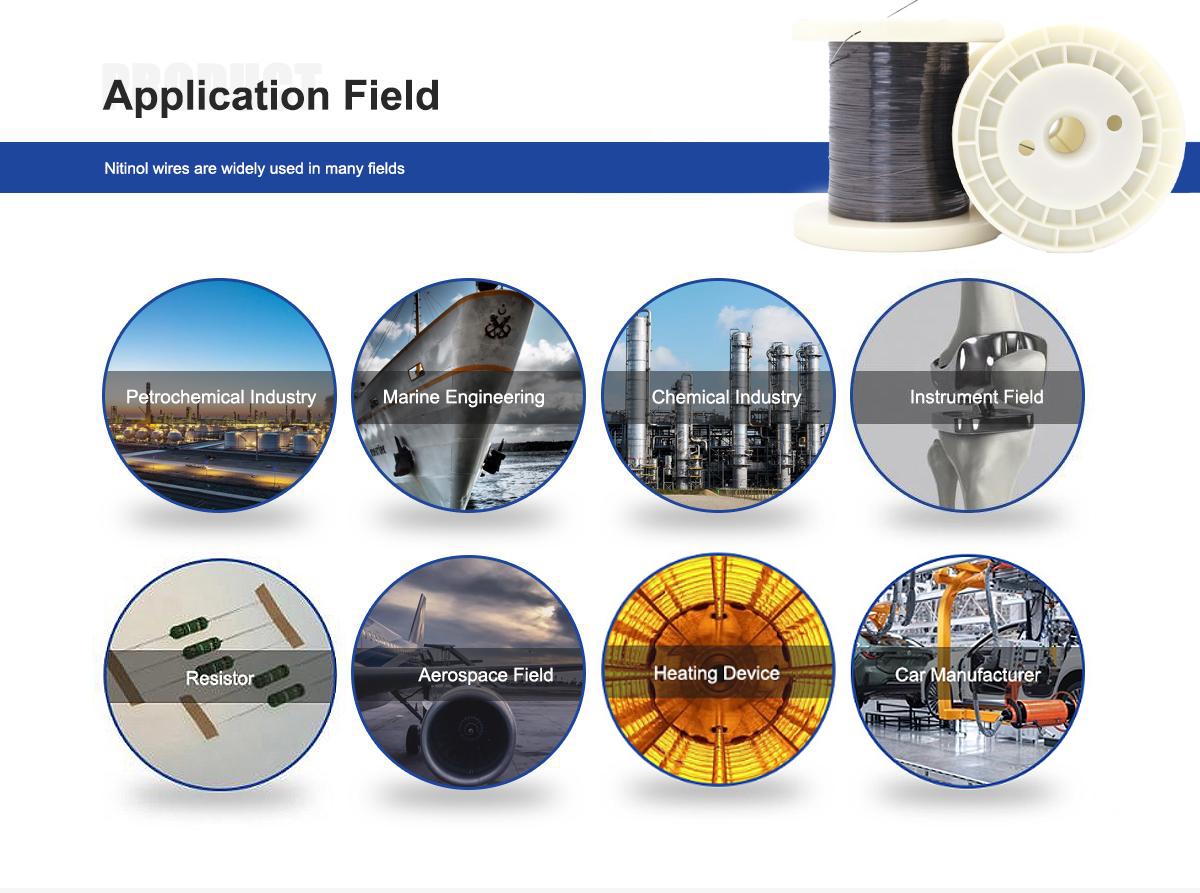

Applications of Nickel-Titanium Wire (Nitinol)

Robotics Applications

Artificial Muscles: NiTi is at the forefront of robotics innovation, particularly in creating soft actuators that mimic human muscle. These artificial muscles can be used in prosthetics and robotic systems, allowing for smoother and more natural movements, which are essential for tasks requiring fine motor skills.

Flexible Joints: The flexibility and resilience of NiTi make it perfect for robotic joints. They can withstand repeated movements without fatigue, enabling robots to perform complex tasks in manufacturing, surgery, and even exploration.

Detailed Photos

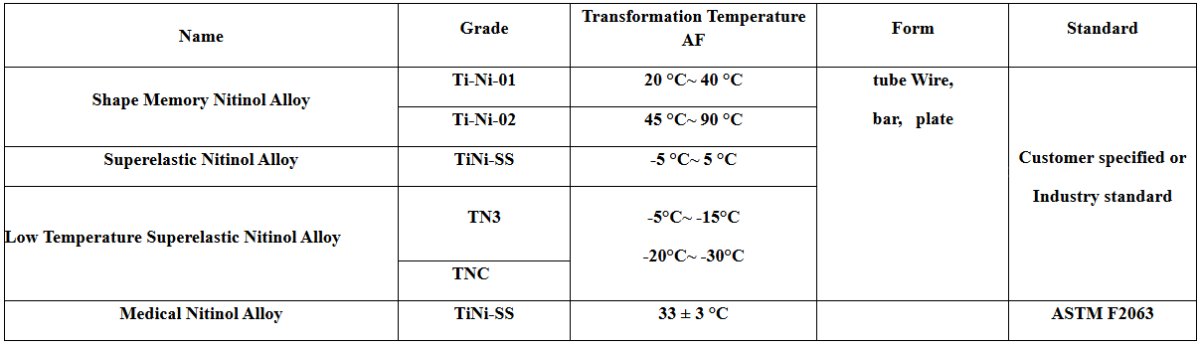

Product Parameters

Recommended products

Company Profile

Our company Principle is " Quality first, Customer first".

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

If any requirements and questions, please feel free to reach:

Sophie Wang | Sales +86 19906119641

International Sales Depart.

Jiangsu Victory Technology Co., Ltd

A: NO.32 West Taihu Road, Xinbei District, Changzhou, Jiangsu

FAQ

Previous article:High-Toughness NiTi for Improvements in Sports Equipment

Next article:Flexible NiTi for Advancements in Wearable Technology